Basic Info.

Product Description

Welding Wire Er70-G CO2 Gas Shielded Solid Er100s-G

ER100S-G is 690 N/mm2 grade high toughness low alloy steel solid welding wire which is shielded by rich-argon gas. It has excellent welding performance with smooth arc and low spatter level which is permitted for all-positions welding work.

Application: ER100s-g is mainly used in shipbuilding, pipelines, engineering machinery, containers, petrochemicals, boilers, pressure vessels, overweight buildings, high-rise buildings, and structures, etc..

Model No.: AWS A5.28 ER100S-G

Flux containing: Not containing flux

Gas: required

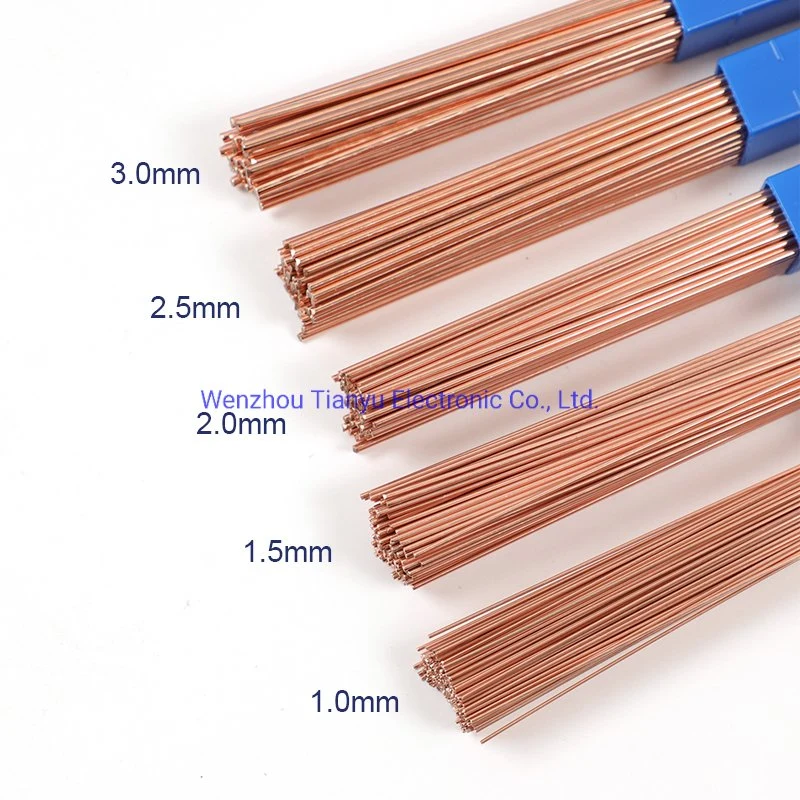

Diameter: Φ0.6mm. Φ0.8mm, Φ0.9mmΦ1.0 mm.Φ1.1 mm.Φ1.2 mmΦ1.6 mm,Φ2.0mm

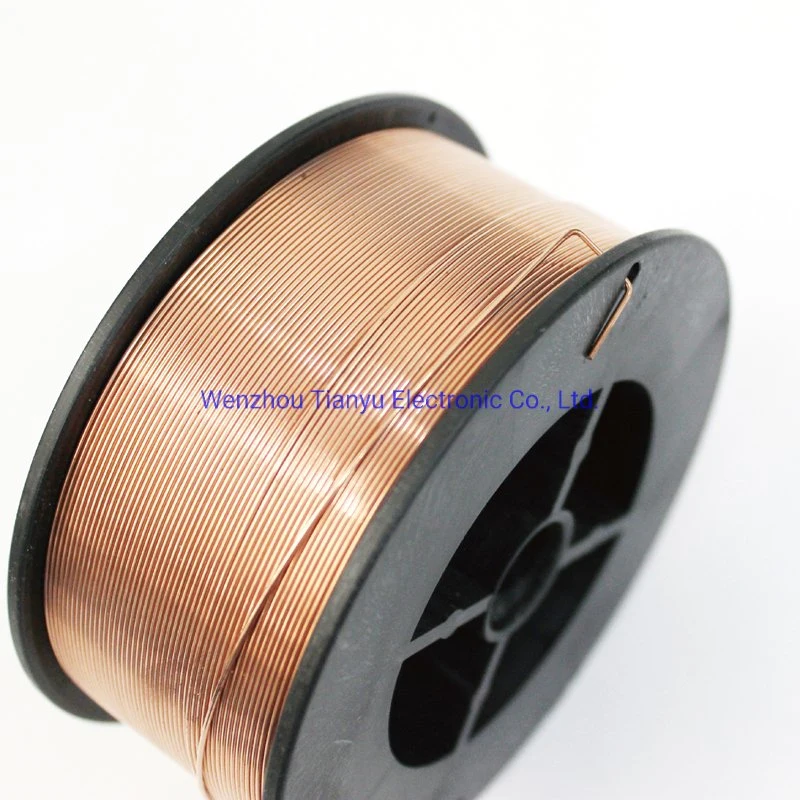

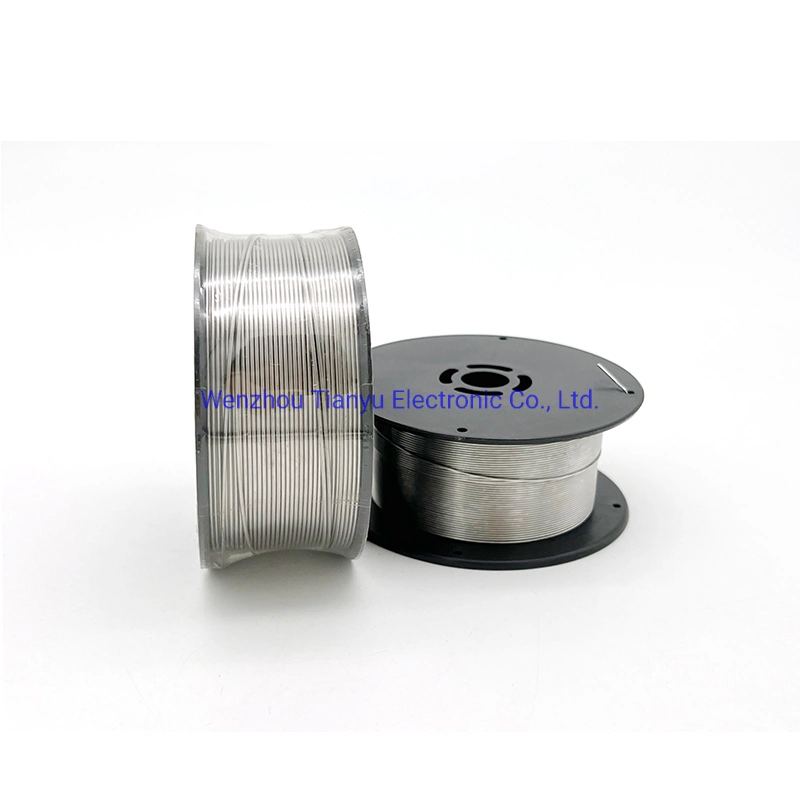

Type: Rolling wire(MIG) Rod(TIG)

Weight: spool(1kg,5kgs,15kgs,20kgs), drum packing(125kgs, 250kgs,350kgs)

Export Markets: Global

Description: A gas shield copper coated carbon steel welding wire for fabrication of mild steel.It provides excellent usability with stable arc, less spatter, good bead appearance. The weld metal has excellent mechanical performance and less sensitive to pores

Application: Used for carbon steel and alloy steel with500MPA tensile strength structures welding, and highspeed welding of sheet plates and pipelines

Diameters: 0.6mm-4.0mm

Chemical Composition of Deposited Metal (%)

Model | Secifications | C | Mn | Si | S | P | Cr | Ni | Cu | Mo | Ti | V |

ER80S-B2 | 0.6mm 0.8mm 0.9mm 1.0mm 1.2mm 1.4mm 1.6mm 2.0mm | 0.07-0.12 | 0.4-0.7 | 0.4-0.7 | ≤0.025 | ≤0.025 | 1.2-1.5 | ≤0.2 | ≤0.35 | 0.4-0.65 | - | - |

ER80S-G | ≤0.1 | 1.2-1.6 | ≤0.06 | ≤0.02 | ≤0.025 | 0.3-0.9 | 0.2-0.6 | 0.2-0.5 | - | - | - | |

ER90S-G | ≤0.1 | 1.4-1.8 | 0.5-0.8 | ≤0.025 | ≤0.025 | - | 0.7-1.5 | ≤0.5 | 0.3-0.6 | ≤0.12 | - | |

ER100S-G | ≤0.1 | 1.4-1.8 | 0.5-0.8 | ≤0.025 | ≤0.025 | 0.15-0.25 | 1.2-1.6 | ≤0.5 | 0.3-0.6 | ≤0.1 | - | |

ER110S-G | ≤0.1 | 1.4-1.8 | 0.4-0.7 | ≤0.025 | ≤0.025 | - | 1.6-2.4 | ≤0.5 | 0.3-0.6 | - | - |

Mechanical Properties of Deposited Metal (%)

Model | Yield point Rm(Mpa) | Tensile strength Rel/Rp0.2(Mpa) | Elongation A(%) | KV2(J) Temp(ºC) | KV2(J) AKV(J) |

ER80S-B2 | 620 | 520 | 22.5 | -20 | - |

ER80S-G | ≥550 | ≥450 | ≥22 | -20 | ≥60 |

ER90S-G | ≥620 | ≥490 | ≥19 | -20 | ≥47 |

ER100S-G | ≥690 | ≥610 | ≥16 | -20 | ≥27 |

ER110S-G | ≥790 | ≥690 | ≥17 | -20 | ≥27 |