Basic Info.

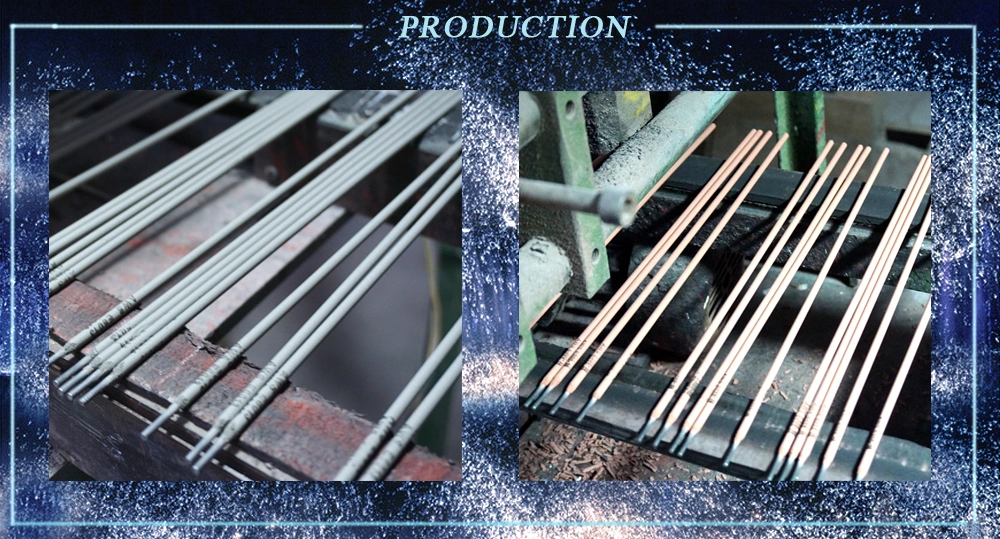

Product Description

Stainless Steel Flux Welding Wire AWS E309LT1-1 for down position welding

Type : AWS E309LT1-1

Material : Stainless Steel Flux Welding Wire

Feature : good at down position welding

Chemical Compisition

| Chemical composition of deposited metal(%) | ||||||||

| C | Mn | Mo | Si | S | P | Ni | Cr | Cu |

| 0.025 | 1.54 | 0.18 | 0.45 | 0.01 | 0.01 | 13.50 | 24.22 | 0.25 |

Description

AWS E309LT1-1 is one flux cored of stainless steel welding wire with ultra low carbon. The weld metal has good mechanical properties, corrosion resistance and crack resistance. Also AWS E309LT1-1 has good welding process performance, stable arc, small splash, Good shape, can be all -position welding.

Used in petrochemical, pressure vessel and other industries

Advantages

1.Little Spatter

2. Excellent welding process

3. Very good for machinable

4.Pure nickel core

5. Both AC and DC applicable

6. Weldment: no need to preheat, good crack resistibility and process-ability

Packaging & shipping

For stainless steel MIG Flux cored wire:

15kg/coil, into carton box, 1 ton/pallet;

OR as clients' requirement

For stainless steel TIG wire:

5kg/plastic tube, 500kgs per wooden case.

Delivery:

Time: Normally ready goods within 8 to 25 days.

Term: CIF CNF FOB EXW

Guaranteed

Gas AWS E309LT1-1 Mig soldering wire flux core welding

1.Best price offer

2.On-time delivery

3.Strict quality control

4.The most comprehensive and the most attentive service

ATTENTION:

1. The surface impurities such as oil stain, rust and water must be removed completely at the welding place to prevent welding Pores, cracks,

etc. will be produced during welding, and metal will be ground out on and around the groove surface during cleaning Luster.

2. In order to obtain good mechanical properties of the welding seam, it is recommended to use pure shielding gas for welding .The flow rate of

protective gas is 20-25l / min, and the dry elongation is 15-25mm .It's better to be in between.

3. the above welding methods, conditions and specifications are for reference only before welding formal products, process qualification

should be carried out according to their own welding characteristics.

About us

We are Hangzhou Lin an Dayang Welding Material Co., Ltd., one of leading manufacturing enterprises in China,specialized in making consumables like welding electrodes, welding wire, for 25years.