Basic Info.

Surface

Copper Coated or Copper Free

Packing Type

5kg/15kg/20kg/250kg/350kg

Shield Gas

100% CO2

Sample

Free Sample

Specification

0.6/0.8/0.9/1.0/1.2/1.4/1.6/2.0mm

Trademark

TYUE

Origin

China

HS Code

722330000

Production Capacity

7500000tons/Year

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 120.00cm

Package Gross Weight

15.500kg

Product Description

Product Description

CO2 Mig Welding Wire ER70S-6 Gas Shielded

MIG welding wire AWS A5.18 ER70S-6,is a kind of carbon steel shielded welding wire. The melting speed of welding wire is fast when welding. It has stable arc, low spatters and beautiful appearance. Good corrosion-resistant on surface of base material. Decrease the probability of blowhole formation. All position welding has good performance CO2 or Ar+CO2 can be used as shielded gas.

Confirm with Standard:

GB/T ER50-6/ DIN SG2/ JIS YGW12

AWS ER70S-6/ BS A18/ EN G3Si1

Main Characteristics:

1. Low welding costs.

2. High productivity and low electricity consumption.

3. Easy to operate. All-position welding.

4. Very low hydrogen content in the weld and lower nitrogen content. Excellent crack-resistance.

5. Little deformation after welding.

6. Wide applicability. Suitable for welding thin, medium and thick plates.

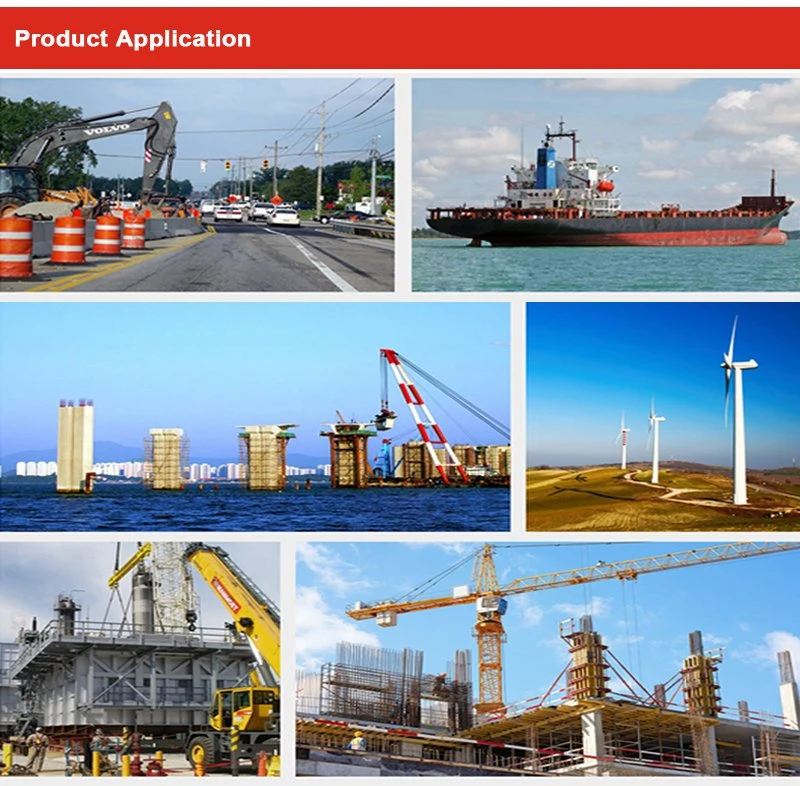

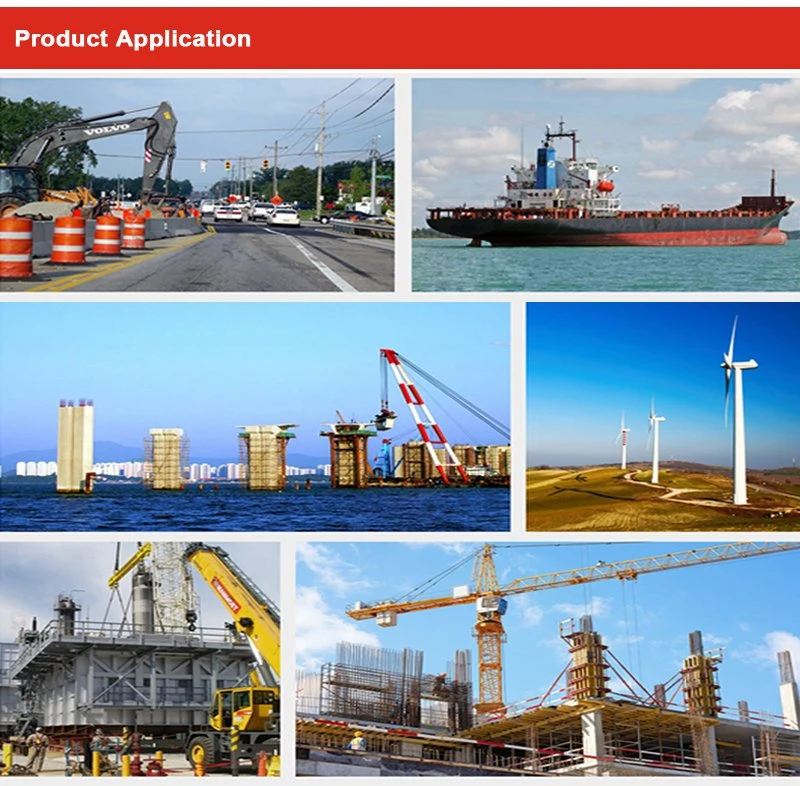

Application:

AWS A5.18 ER70S-6

1. Used for welding all kinds of 500MPa structural steel parts.

2. Used for welding all kinds of 500MPa plates and pipes.

Chemical Composition(%)

Mechanical Properties of Deposited Metal

Reference Current(DC+)

CO2 Mig Welding Wire ER70S-6 Gas Shielded

MIG welding wire AWS A5.18 ER70S-6,is a kind of carbon steel shielded welding wire. The melting speed of welding wire is fast when welding. It has stable arc, low spatters and beautiful appearance. Good corrosion-resistant on surface of base material. Decrease the probability of blowhole formation. All position welding has good performance CO2 or Ar+CO2 can be used as shielded gas.

| Detail Information | |||

| Product Name: | Cooper Cotaed Welding Wire ER70S-6 | Model: | ER70S-6 |

| Brand: | TYUE | Diameter: | 0.8/0.9/1.0/1.2/1.6mm |

| Weight: | 5kg/15kg/20kg/250/350kg | Surface: | Cooper Plating |

| Spool Material: | Black Plastic Spool/steel | Packing: | Color Box/bucket |

| OEM: | Accept | Diameter Of Spool: | 100/200/270/300mm |

Confirm with Standard:

GB/T ER50-6/ DIN SG2/ JIS YGW12

AWS ER70S-6/ BS A18/ EN G3Si1

Main Characteristics:

1. Low welding costs.

2. High productivity and low electricity consumption.

3. Easy to operate. All-position welding.

4. Very low hydrogen content in the weld and lower nitrogen content. Excellent crack-resistance.

5. Little deformation after welding.

6. Wide applicability. Suitable for welding thin, medium and thick plates.

Application:

AWS A5.18 ER70S-6

1. Used for welding all kinds of 500MPa structural steel parts.

2. Used for welding all kinds of 500MPa plates and pipes.

Chemical Composition(%)

| Chemical Composition | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu |

| Guarantee Value | 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 | ≤0.50 |

| General Result | 0.077 | 1.45 | 0.87 | 0.013 | 0.012 | 0.017 | 0.031 | 0.002 | 0.004 | 0.125 |

Mechanical Properties of Deposited Metal

| Test Item | Rm(MPa) | ReL/Rp0.2(MPa) | A(%) | KV2(J) |

| -40ºC | ||||

| Guarantee Value | ≥500 | ≥420 | ≥22 | ≥47 |

| General Result | 555 | 450 | 29 | 77/95/83 |

Reference Current(DC+)

| Size(mm) | Current range (A) | GAS flow rate(L/min) |

| Φ0.8 | 50~100 | 15 |

| Φ1.0 | 50~220 | 15~20 |

| Φ1.2 | 80~350 | 15~25 |

| Φ1.6 | 170~550 | 20~25 |