- Overview

- Product Description

Basic Info.

Product Name

Stainless Steel 304 Braided Mesh Metal Flexible Ho

Working Pressure

1.6/2.5MPa

Working Temperature

-10ºC-+300ºC

Installation Length

Support Customization

Transport Package

Based on Customer′s Needs

Specification

DN8-DN400

Trademark

FLK

Origin

Wenzhou, Zhejiang, China

HS Code

7307210000

Production Capacity

10000ton/Year

Product Description

| Product Description | ||||

| Product Name | Stainless Steel Braided Hose | |||

| Standard | ASTM JIS GB BS EN DIN | |||

| Material | 201 202 303 304 304L 309S 310 310S 314 316 316L 630 840 904L and so on | |||

| Inner Tube Material | Buna-N PVC EPDM and other materials | |||

| Type | Single head pipe, Braided pipe , Shower pipe | |||

| Fitting Type | Flat, Ball, Bell, Welded outer wire | |||

| Inside Diameter | 8.5-56.5mm | |||

| Outside Diameter | 9.5-58mm | |||

| Package | Standard or Customized | |||

| MOQ | 100pcs | |||

| Application | Mainly used for electrical line protection and household faucets, toilets, showers and other pipe connectors | |||

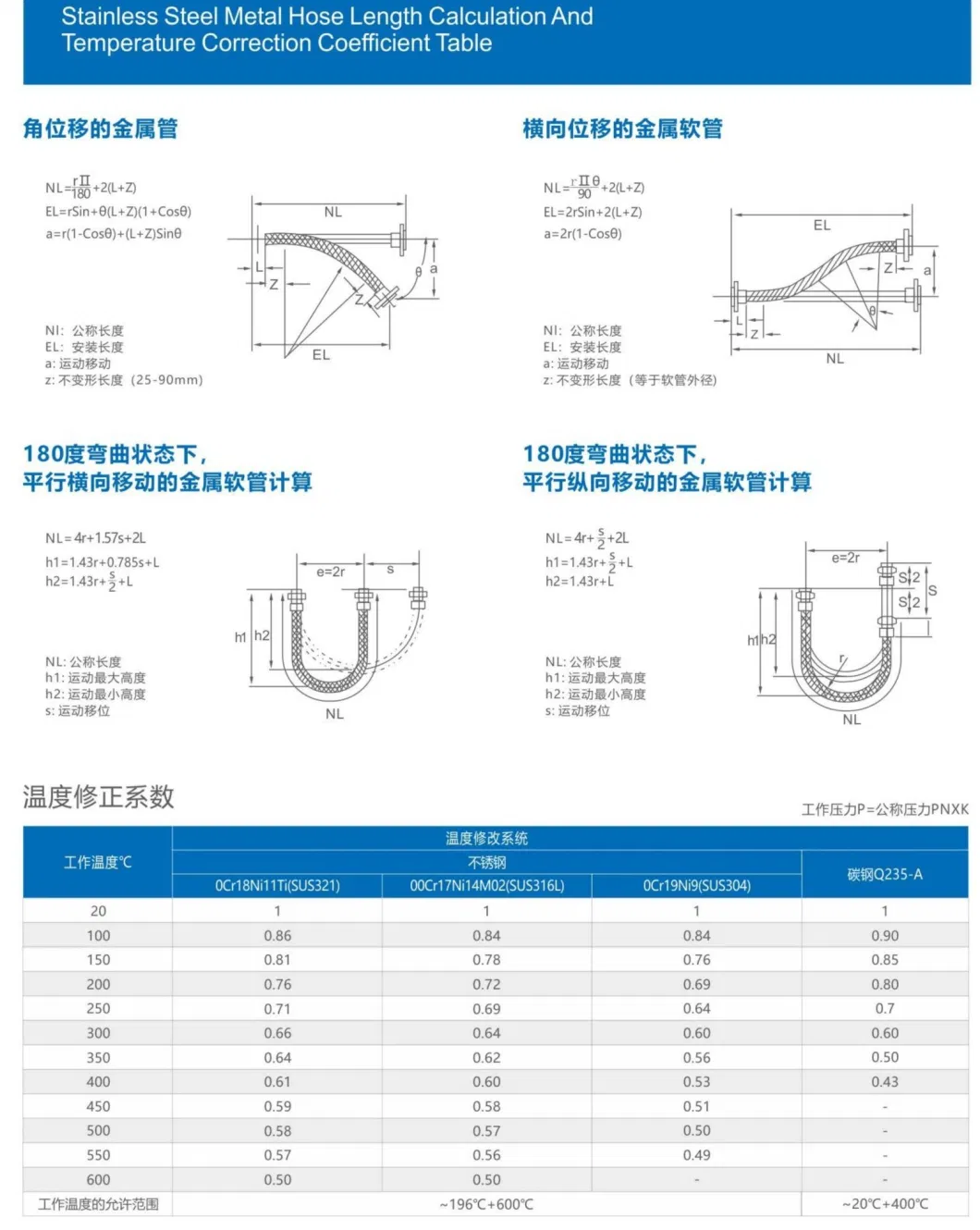

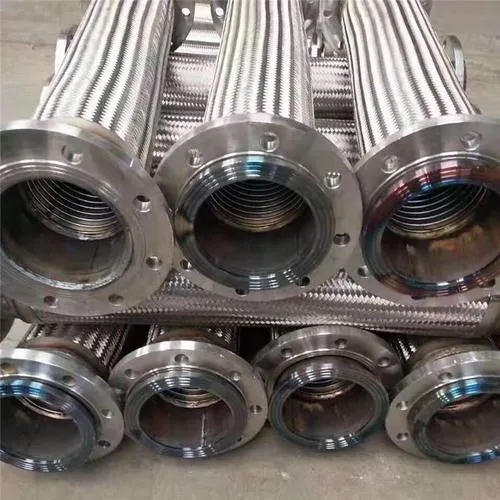

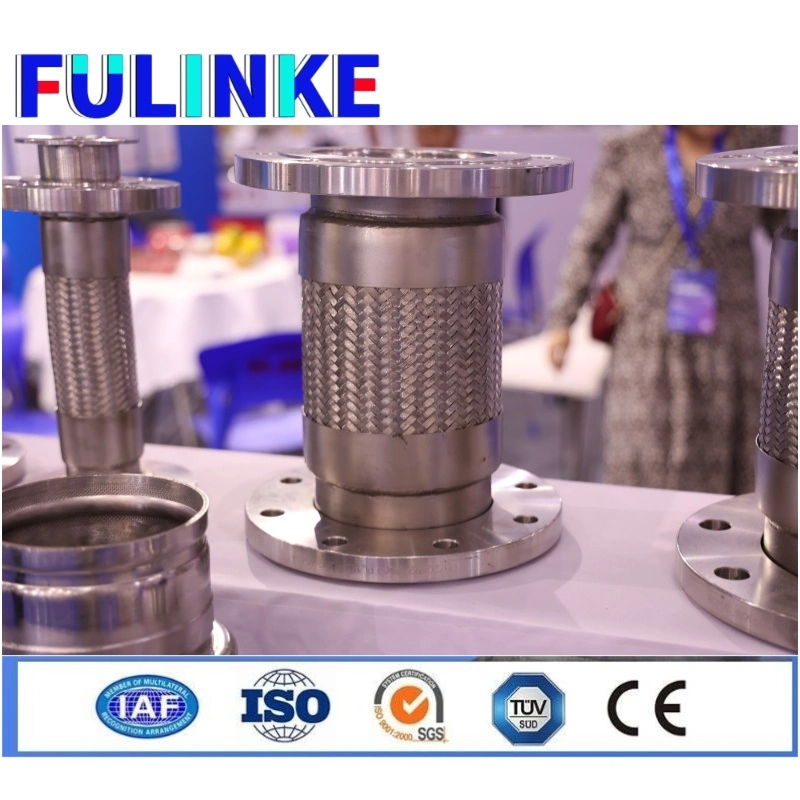

Metal hose is composed of metal bellows, braided metal mesh sleeves, joints, and three other major components.

1. Metal bellows: as the body of the metal hose, metal bellows have spiral and ring types. My factory's spiral metal hose, with a diameter of 6–10 mm, is a seamless, thin-walled metal tube. Bad spin molding, with a diameter of 15–400 mm, is a thin-walled metal tube with seams extruded from the ring bellows.

2. mesh sleeve: mesh sleeve by a number of metal wires or metal bands (stainless steel) in a certain order to weave into a mesh cage-like set on the surface of the bellows. It can not only ensure that the radial, axial static load and fluid flow along the pipeline when the pulsating effect of the conditions can work safely and reliably, but also ensure that the corrugated part of the direct acceptance of bumping, friction, collision and other aspects of mechanical damage.

3. Fitting: Fitting is a metal hose and piping or equipment connected to the components; it ensures that the fluid in the piping system works properly. The most commonly used fittings are threaded connections, quick coupling and flange connections. The most commonly used fittings are threaded, quick couplings and flanged. Metal hose with a diameter of 6–40 is mainly used in threaded connections and quick coupling. Quick couplings are made according to user requirements. Medium and large diameters (40–400) are mainly connected by flanges. It can also be made into a flange-type quick coupling. The joints are made of carbon steel, stainless steel, brass and other materials. The flange standard is according to JB81-94: production joints and metal hose joints are welded (6–10) and arc welding (15–400) welded. The metal hoses in our factory are inflated, leakage checked and hydrostatic tested. (1.35–1.5 working pressure).

Q1. Where is your factory?

A1: Our company's processing center is located in Wenzhou, Zhejiang, China.

Equipped with various types of machinery and equipment, such as laser cutting machines and mirror polishing machines, we can provide a variety of personalized services according to customer needs.

Q2. What are your company's main products?

A2: Our main products are stainless steel plates, coils, round or square tubes, bars, channel steel pipe fittings, etc.

Q3. How do you control quality?

A3: Factory testing and certification are provided upon shipment, and third-party inspection is available.

Q4. What are your company's strengths?

A4: We have many professionals and technicians, more competitive prices and better after-sales service than other stainless steel companies.

Q5. How many countries have you exported to?

A5: Exported to more than 50 countries, mainly from the United States, Russia, United Kingdom, Kuwait, Egypt, Turkey, Jordan,

India etc.

Q6. Can you provide samples?

A6: There are small samples in the store. We can provide samples for free. The customer needs to bear the shipping cost.

Customized samples will take about 5-7 days.