Basic Info.

Model NO.

hard facing weldingwire

Net Weight

Net Weight: 5kg/Spool,15kg/Spool,20kg/Spool

Flux Content

1.3%

Color

Brass Surface

Transport Package

5kg/Spool, 15kg/Spool, 20kg/Spool

Specification

ER70S-6

Trademark

solid

Origin

Shandong China

HS Code

722992000

Production Capacity

1000000metric Ton

Product Description

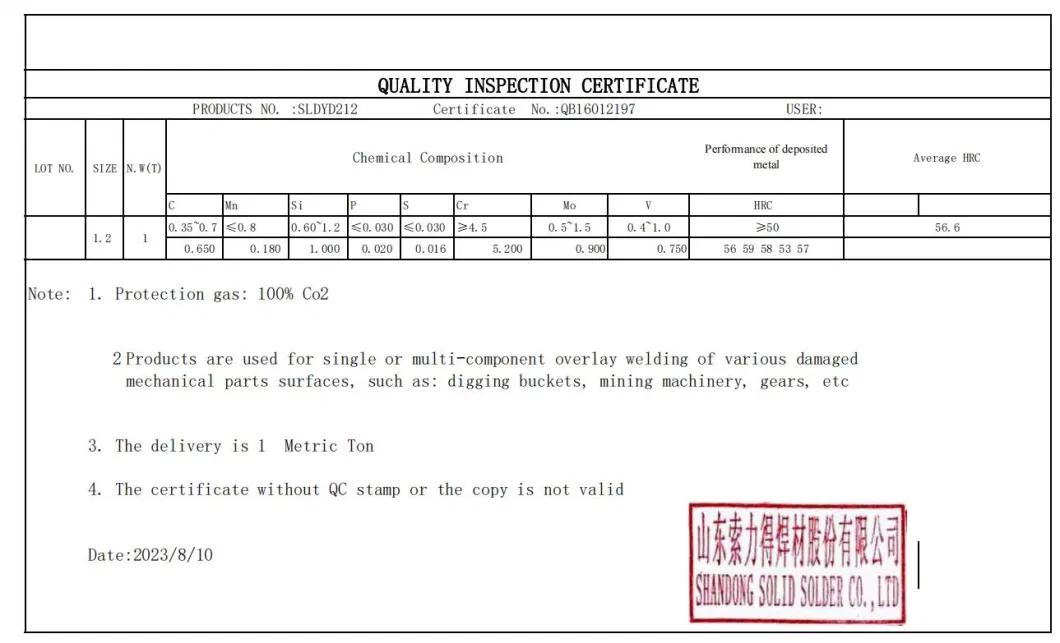

hard facing welding wire SLDYD212 HRC 56.6

Quick Details

Place of Origin: Shandong China (Mainland) Brand Name: Solid Brand Model Number: SLDYD212

Material: CO2 Diameter: 2 0.8, 1.0, 1.2, 1.6mm Melting Point: 1300

Net Weight: 5kg/spool, 15kg/spool, 20kg/spool Flux Content: 1.3% Color: Brass Surface Coated: Copper

ISO: 9001 type1: Aluminium welding wire(MIG, TIG) type2: Stainless steel wire(MIG, TIG)

Packaging & DeliveryPackaging Detail:

-spool packed on pallet

-Delivery Detail: Within 10 days

Specifications SLDYD212(CO2 welding wire)

1. Gas shielded welding wire

2. Excellent working performace, stable welding quality

3. Pass ISO9001

We are manufacturer and adopt elaboration management.

1. Our welding wire can be welding with shielding gas ( C02, CO2+Ar...)

2. Our welding wire is with excellent welding technological properties, fast melting rate, stable arc, less spatter, high depositing efficiency, beautiful seam...It is suitable for all positions.

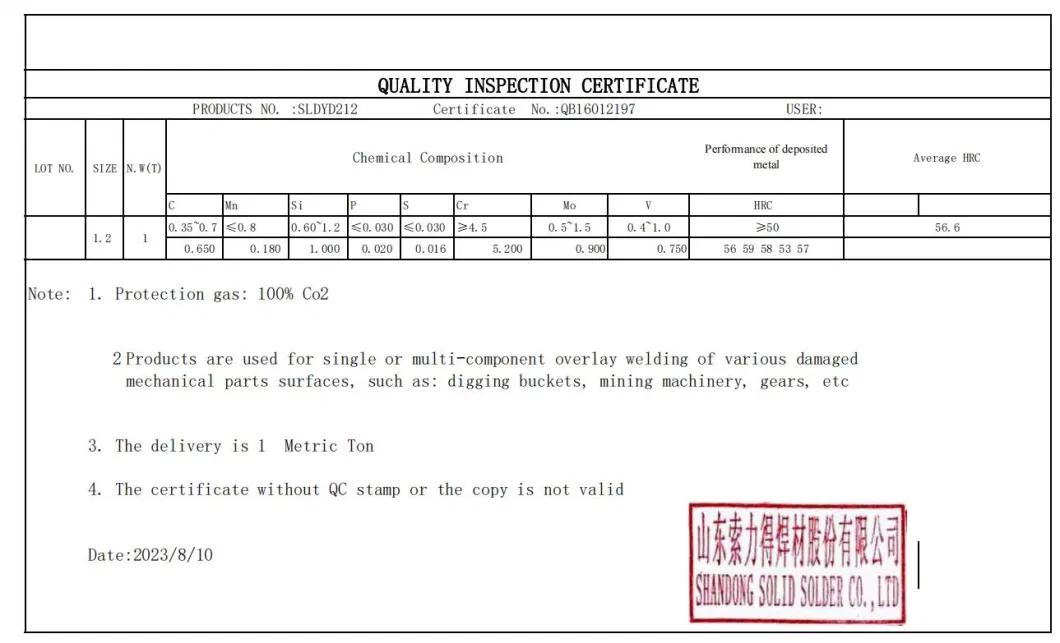

Quick Details

Place of Origin: Shandong China (Mainland) Brand Name: Solid Brand Model Number: SLDYD212

Material: CO2 Diameter: 2 0.8, 1.0, 1.2, 1.6mm Melting Point: 1300

Net Weight: 5kg/spool, 15kg/spool, 20kg/spool Flux Content: 1.3% Color: Brass Surface Coated: Copper

ISO: 9001 type1: Aluminium welding wire(MIG, TIG) type2: Stainless steel wire(MIG, TIG)

Packaging & DeliveryPackaging Detail:

-spool packed on pallet

-Delivery Detail: Within 10 days

Specifications SLDYD212(CO2 welding wire)

1. Gas shielded welding wire

2. Excellent working performace, stable welding quality

3. Pass ISO9001

We are manufacturer and adopt elaboration management.

1. Our welding wire can be welding with shielding gas ( C02, CO2+Ar...)

2. Our welding wire is with excellent welding technological properties, fast melting rate, stable arc, less spatter, high depositing efficiency, beautiful seam...It is suitable for all positions.