- Overview

- Company Profile

- FAQ

Basic Info.

Product Description

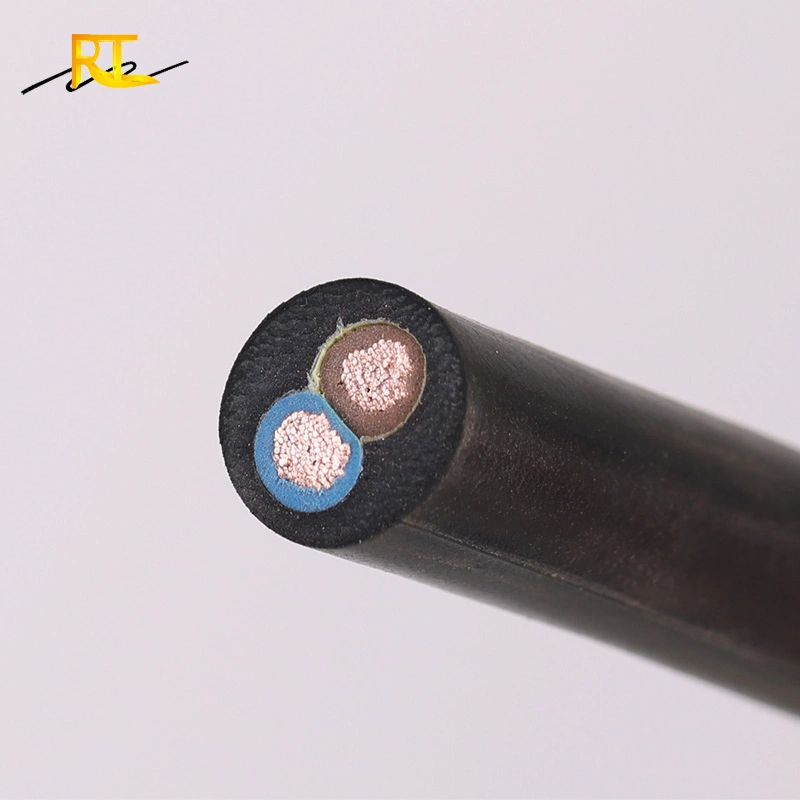

Flexible Copper Conductor Rubber Insulated Electric Welding Wire Cable 16mm2

- Conductor: Stranded Bare Copper acc. to IEC 60228, EN 60228, VDE 0295, class 5

- Insulation: Synthetic Rubber, EI4 acc. to DIN VDE 0282 part 1 + HD 22.1

- Conductor Color Coding: acc. to HD 308 (VDE 0293-308)

- Conductor Stranding: from 2 conductors stranded in layers

- Jacket: Synthetic Rubber, EM2 acc. to DIN VDE 0282 part 1 + HD 22.1

- Jacket Color: Black

H07RN-F Cable Technical Data:

- Nominal Voltage: Uo/U 450/750 volts

- Testing Voltage U: 2500 volts acc. to DIN VDE 0282 part 2 + HD 22.2

- Min. Bending Radius: 15 x O.D.

H07RN-F Cable Ratings & Approvals:

- Temperature Range: -25°C to +60°C

- VDE

- CE

Working voltage and temperature:

H07RN-F model rated voltage U0/U IS 450/750V

H05RN-F model rated voltage U0/U IS 300/500V

H05RR-F model rated voltage U0/U IS 300/500V

Long time allow working temperature of wire core cant be higher than 60C

| Type | Nominal Section (mm²) | Structurer of Conductor Core No./Dia.(mm) | Insulation Thickness (mm) | Jacket Thickness (mm) | Overall Diameter (mm) | Rated Voltage | Max. Conductor Resistance at 20ºC (Ω/KM) |

| H07RN-F | 1X1.5 | 30/0.25 | 0.8 | 1.4 | 6.2±0.2 | 450/750V | 13.3 |

| 1X2.5 | 49/0.25 | 0.9 | 1.4 | 6.6±0.2 | 450/750V | 7.98 | |

| 1X4 | 56/0.3 | 1 | 1.5 | 7.9±0.3 | 450/750V | 4.95 | |

| 1X6 | 84/0.3 | 1 | 1.6 | 8.7±0.3 | 450/750V | 3.3 | |

| 2X1 | 32/0.2 | 0.8 | 1.3 | 8.3±0.3 | 450/750V | 19.5 | |

| 2X1.5 | 30/0.25 | 0.8 | 1.5 | 9.3±0.3 | 450/750V | 13.3 | |

| 2X2.5 | 49/0.25 | 0.9 | 1.7 | 11.2±0.4 | 450/750V | 7.98 | |

| 2X4 | 56/0.3 | 1 | 1.8 | 12.8±0.4 | 450/750V | 4.95 | |

| 2X6 | 84/0.3 | 1 | 2 | 14.4±0.4 | 450/750V | 3.3 | |

| 3X1 | 32/0.2 | 0.8 | 1.4 | 9±0.3 | 450/750V | 19.5 | |

| 3X1.5 | 30/0.25 | 0.8 | 1.6 | 10.1±0.4 | 450/750V | 13.3 | |

| 3X2.5 | 49/0.25 | 0.9 | 1.8 | 12.1±0.4 | 450/750V | 7.98 | |

| 3X4 | 56/0.3 | 1 | 1.9 | 13.9±0.4 | 450/750V | 4.95 | |

| 3X6 | 84/0.3 | 1 | 2.1 | 15.4±0.5 | 450/750V | 3.3 | |

| 4X1 | 32/0.2 | 0.8 | 1.5 | 10±0.4 | 450/750V | 19.5 | |

| 4X1.5 | 30/0.25 | 0.8 | 1.7 | 11.1±0.4 | 450/750V | 13.3 | |

| 4X2.5 | 49/0.25 | 0.9 | 1.9 | 13.3±0.4 | 450/750V | 7.98 | |

| 4X4 | 56/0.3 | 1 | 2 | 15.2±0.5 | 450/750V | 4.95 | |

| 4X6 | 84/0.3 | 1 | 2.3 | 17.2±0.5 | 450/750V | 3.3 | |

| 5X1 | 32/0.2 | 0.8 | 1.6 | 11±0.4 | 450/750V | 19.5 | |

| 5X1.5 | 30/0.25 | 0.8 | 1.8 | 12.2±0.4 | 450/750V | 13.3 | |

| 5X2.5 | 49/0.25 | 0.9 | 2 | 14.6±0.5 | 450/750V | 7.98 | |

| 5X4 | 56/0.3 | 1 | 2.2 | 16.9±0.5 | 450/750V | 4.95 | |

| 5X6 | 84/0.3 | 1 | 2.5 | 19.1±0.6 | 450/750V | 3.3 |

| Type | Nominal Section (mm²) | Structurer of Conductor Core No./Dia.(mm) | Insulation Thickness (mm) | Jacket Thickness (mm) | Overall Diameter (mm) | Rated Voltage | Max. Conductor Resistance at 20ºC (Ω/KM) |

| H03RN-F | 1X0.5 | 16/0.2 | 0.6 | 0.6 | 3.4 | 39 | |

| 1X0.75 | 24/0.2 | 0.6 | 0.6 | 3.6 | 26 | ||

| H05RN-F | 2X0.75 | 24/0.2 | 0.6 | 0.8 | 6.3 | 26 | |

| 2X1 | 32/0.2 | 0.6 | 0.8 | 6.7 | 19.5 | ||

| 3X0.75 | 24/0.2 | 0.6 | 0.9 | 6.8 | 26 | ||

| 3X1 | 32/0.2 | 0.6 | 0.9 | 7.2 | 19.5 |

| Welding Cable Data Sheet | ||||||

| Nominal Section (mm²) | Structure of conductor | Overall Diameter (mm) | Max. Conductor Resistance at 20ºC | Approx. Weight (KG/KM) | ||

| Core No./Dia.(mm) | Min. | Max. | Ω/KM | YH | YHF | |

| 10 | 322/0.2 | 7.1 | 9.2 | 19.1 | 146 | 154 |

| 16 | 513/0.2 | 8.8 | 11 | 1.16 | 219 | 231 |

| 25 | 798/0.2 | 10.1 | 12.7 | 0.758 | 318 | 332 |

| 35 | 1121/0.2 | 11.4 | 14.2 | 0.554 | 426 | 440 |

| 50 | 1596/0.2 | 13.2 | 16.5 | 0.386 | 593 | 610 |

| 70 | 2214/0.2 | 15.3 | 19.2 | 0.272 | 790 | 818 |

| 95 | 2997/0.2 | 17.1 | 21.4 | 0.206 | 1066 | 1103 |

| 120 | 1702/0.3 | 19.2 | 23.5 | 0.161 | 1349 | 1393 |

| 150 | 2135/0.3 | 21.2 | 26.4 | 0.129 | 1688 | 1699 |

| 185 | 1443/0.4 | 22.2 | 28.3 | 0.106 | 1984 | 2020 |

Ruitian Cable established in 2008, is a professional manufacturer engaged in research, development, production, sale and service of power cable, solar cable, control cable, electric wire, rubber cable, aerial bundle cable, high temperature cable ect. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.

Ruitian Cable established in 2008, is a professional manufacturer engaged in research, development, production, sale and service of power cable, solar cable, control cable, electric wire, rubber cable, aerial bundle cable, high temperature cable ect. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.

We have many advanced equipment including testing, insulation, shielding, cabling and packing. In addition, With continuous efforts of production improvements and high quality management, we have obtained certificates TUV, C E, I S O 9 0 0 1, I S O 1 4 0 0 1 and Industrial Products Manufacture Certificate. Has exported to Europe, America, Southeast Asia, Middle east, Australia, Africa. Our products gain wide praises all around the world. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.

We warmly welcome customers from all around the world to cooperate with us for common success.

1).When can I get the price?

We usually quote within 6 hours after we get your inquiry. If you are very urgent to get the price, pleasecall us or tell us in your e-mail so that we will regard your inquiry priority.

(2).How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. Sample is free, but the freight charge should be paid.

(3).How long can I expect to get the sample?

After you pay the freight charge and send us confirmed files,the samples will be ready for delivery in 37 days. The samples will be sent to you via express and arrive in 3~5 days. You can use your own express account orprepay us if you do not have an account.

(4).What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order.The best record we keep is delivering 10 kilometers cable within a week. Generally speaking, we suggest that you start inquiry two months before the date you would like to get the products at your country.