Basic Info.

Model NO.

AWS E308-16

Slag Characteristic

Acidic

Stainless Steel Welding Rod Type

Chromium Stainless Steel

Function

Surfacing Electrode, Low Hydrogen Type Electrode, Hardfacing Electrode, High Efficient Iron Powder Electrode, Gravity Electrode, Moisture-Proof Electrode, Stainless Electrode

Welding Power

DC/AC

Transport Package

5kg/Box, 20kg/Carton

Specification

2.5mm/3.2mm/4.0mm

Trademark

TYUE

Origin

China

HS Code

831110000

Production Capacity

5000000 Ton/Year

Product Description

WENZHOU TIANYU ELECTRONIC CO., LTD.

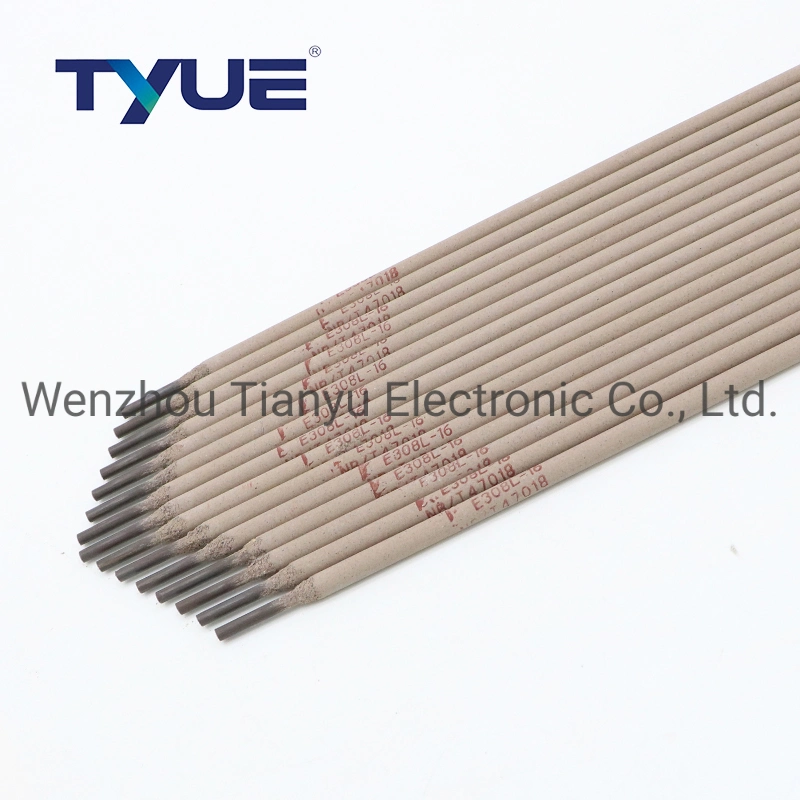

Stainless Steel Welding Electrode/Rod

AWS A5.4 E308L-16

GB/T 983 E308L-16

ISO 3581-B-ES308L-16

APPLICATIONS:

It is suitable for welding low carbon 00cr18ni9 stainless steel structure, also can be used to the corrosion resistance of stainless steel structure,such as the 0cr19ni11ti, whose working temperature below 300 ºC, it is mainly used for manufacture of synthetic fiber, fertilizer, oil and other equipment.

FEATURES:

AWS E308L-16 is a coated rutile type of ultra-low carbon Cr18Ni9 stainless steel electrode.Both AC and DC can be used and can be all-position welding. It can reach excellent welding performance, stable arc, little spatter, easy slag removal and good weld appearance. The deposited metal has good resistance to intergranular corrosion.

ATTENTION:

1.Electrode must be approved by 320-350 ºC for 1 hour before welding, dry the electrode when use it.

2. The rust, oil, water and other impurities of the weld must be removed before welding.

3.Recommended DC power supply, because AC welding has a shallow penetration, the current should not be too large, in order to avoid the coating redness and cracking.

4. To minimize the amount of heat input and welding electrode oscillating amplitude shoulds not be too big.

5.Preheat and interlayer-temperature should remain below 150 ºC

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF

SIZE:

2.0*300mm(350mm)

2.5*300mm(350mm)

3.2*350mm

4.0*350mm(400mm)

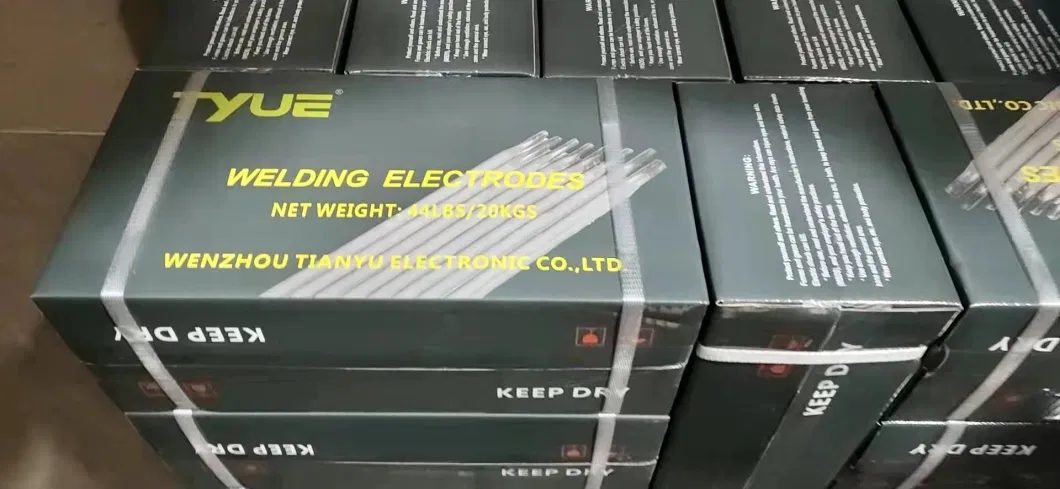

PACKING:

5kg/inner box,

20kg (4box)/outer carton,

1000kgs=1ton=50cartons packed on a pallet.

SPECIFICATION DATA:

| Chemical Composition Deposited Metal (%) | ||||||||

| C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| ≤0.04 | 0.5~2.5 | ≤0.90 | ≤18~21 | 9~11 | ≤0.03 | ≤0.04 | ≤0.75 | ≤0.75 |

| Mechanical Properties of Deposited metal | ||||||||

| Test Item | Tensile Strength ós (Mpa) | Elongation δ5(%) | ||||||

| Guranteed | ≥520 | ≥35 | ||||||

| Sizes & Recommended Current (AC or DC) | |||||

| Welding rod diameter (mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 |

| welding current (A) | 25~50 | 50~80 | 80~110 | 110~160 | 160~200 |

PRODUCT PICTURE:

| FAQ |

Q: What is delivery time / lead time ?

A: 2-3 weeks.

Q: What is your minimum order ?

A: 3000kgs/each size. (MOQ for stainless steel welding electrode)

Q: What is your payment term ?

A: 50% T/T in advance, 50% balance paid before shipment.

Q: Can we visit your factory ?

A: Yes. Welcome to visit our factory at any time.

Q: Can you provide free sampe ?

A: Yes. Free samples are available for you.