Basic Info.

Model NO.

seamless and welded

ASTM A790

ASTM A790 Uns S31803 Duplex Steel Pipe and Tube/

Transport Package

Bundle

Specification

ASTM A790

Trademark

C&N

Origin

China

Production Capacity

500tons/Month

Product Description

Uns S31803 Pipe Suppliers, We stock and Supply Duplex S31803 Rectangular and Square pipe in various size, check Duplex S31803 Seamless Tube Specification.

ASTM A790 S31803 Pip

ASTM A790 UNS S31803 Pipe

Super Duplex Stainless Steel is a highly alloyed, good performance duplex steel with a pitting resistance. Super duplex offers good resistance to pitting and crevice corrosion.Super duplex is suited for use in aggressive environments. It has good resistance to stress corrosion cracking in chloride and sour environments and has good resistance to erosion corrosion and corrosion fatigue.

Application:

Oil and gas industry equipment.

Offshore platforms, heat exchangers, process and service water systems, fire - fighting systems, injection and ballast water system.

Chemical process industries, heat exchangers, vessels, and piping.

Desalination plants, high pressure RO - plant and seawater piping.

Mechanical and structural components, high strength, corrosion - resistant parts.

power industry FGD systems, utility and idustrial scrubber systems, absorber towers, ducting, and piping.

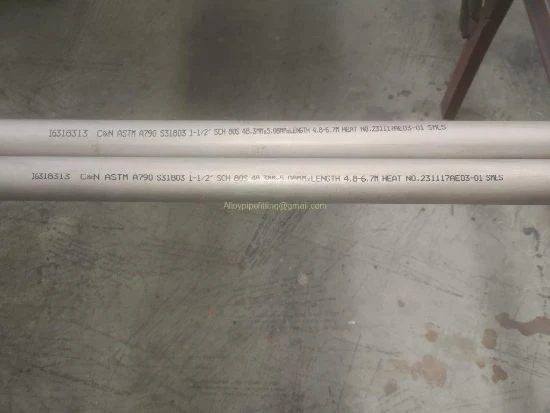

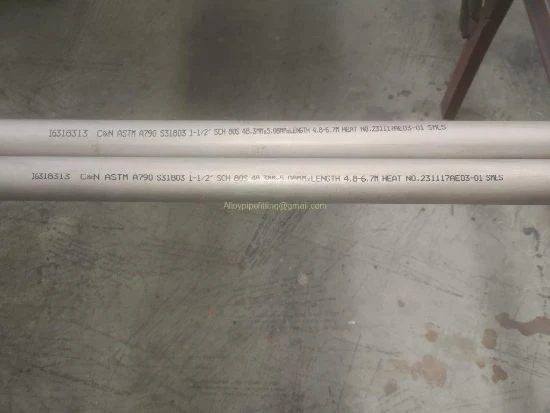

ASTM A790 S31803 8 SCH 10S

ASTM A790 UNS S31803 Pipe MI Test

ASTM A790 UNS S31803 Pipe Thickness Measurement

ASTM A790 UNS S31803 Pipe Dimension Measurement

2507 should be hot worked between 18750F and 22500F. This should be followed by a solution anneal at 19250F minimum and a rapid air or water quench.

Cold Forming:

Most of the common stainless steel forming methods can be used for cold working 2507. The alloy has a higher yield strength and lower ductility than the austentic steels so fabricators may find that higher forming forces, increased radius of bending and increased allowance for springback are necessary. Deep Drawing, stretch forming and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel. When forming requires more than 10% cold deformation, a solution anneal and quench are recommended.

Heat Treatment:

2507 should be solution annealed and quenched after hot or cold forming solution annealing should be done at a minimum of 19250F. (1025 - 1125 centigrade) Annealing should be followed immediately by a rapid air or water quench to obtain maximum corrosion resistance, heat treated products should be pickled and rinsed.

Welding:

2507 possesses good weldability and can be joined to itself or other materials by shielded metal arc welding, gas tungsten arc welding, plasma arc welding, flux cored wire or submerged arc welding. 2507/P100 filler metal is suggested when welding 2507 because it will produce the appropriate duplex weld structure.

Material Standards And Grades ASTM A790 UNS S31803 Pipe

ASTM A790 S31803 Pip

ASTM A790 UNS S31803 Pipe

Detailed description

- Standard: JIS, ANSI, ASTM, GB, DIN, EN

- Place of Origin: ShangHai, China (Mainland)

- Brand Name: C&N HuiTong

- Model Number: seamless and welded

- Steel Grade: UNS32750

- Application: Oil and gas industry equipment.Chemical process industries

- Certification: SGS,TUV

- Thickness: SCH10S to SCHXXS

- Outer Diameter: DN15 ~DN1200

Super Duplex Stainless Steel is a highly alloyed, good performance duplex steel with a pitting resistance. Super duplex offers good resistance to pitting and crevice corrosion.Super duplex is suited for use in aggressive environments. It has good resistance to stress corrosion cracking in chloride and sour environments and has good resistance to erosion corrosion and corrosion fatigue.

Application:

Oil and gas industry equipment.

Offshore platforms, heat exchangers, process and service water systems, fire - fighting systems, injection and ballast water system.

Chemical process industries, heat exchangers, vessels, and piping.

Desalination plants, high pressure RO - plant and seawater piping.

Mechanical and structural components, high strength, corrosion - resistant parts.

power industry FGD systems, utility and idustrial scrubber systems, absorber towers, ducting, and piping.

ASTM A790 S31803 8 SCH 10S

ASTM A790 UNS S31803 Pipe MI Test

Chemical composition%

| C | Cr | Ni | Mo | N | Others |

| 0.020 | 25 | 7 | 4.0 | 27 | S=0.001 |

| Pren= (Cr%)+3.3 (Mo%)+16 (N%) not less than 40 | |||||

Mechanical Performance:

| Ultimate Tensile Strength, Ksi | 116min |

| 0.2%Offset Yield Strength 0.2%, Ksi | 80min |

| 0.1%Offset Yield Strength 0.2%, Ksi | 91min |

| Elongation in 2 inches, % | 15 min |

| Hardness Rockwell C | 32 max |

| Impact Energy, ft. - lbs. | 74min |

Low Temperature Impact Properties:

| Temperature 0F | RT | 34 | - 4 | - 40 |

| Ft - lbs | 162 | 162 | 155 | 140 |

| Temperature 0F | - 76 | - 112 | - 148 | - 320 |

| Ft - lbs | 110 | 44 | 30 | 7 |

Elevated temperature Tensile Properties:

| Temperature 0F | 68 | 212 | 302 | 392 | 482 |

| 0.2%Offset Yield Strength, Ksi | 80 | 65 | 61 | 58 | 55 |

| Ultimate Tensile Strength, Ksi | 116 | 101 | 98 | 95 | 94 |

ASTM A790 UNS S31803 Pipe Thickness Measurement

ASTM A790 UNS S31803 Pipe Dimension Measurement

Processing:

Hot forming2507 should be hot worked between 18750F and 22500F. This should be followed by a solution anneal at 19250F minimum and a rapid air or water quench.

Cold Forming:

Most of the common stainless steel forming methods can be used for cold working 2507. The alloy has a higher yield strength and lower ductility than the austentic steels so fabricators may find that higher forming forces, increased radius of bending and increased allowance for springback are necessary. Deep Drawing, stretch forming and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel. When forming requires more than 10% cold deformation, a solution anneal and quench are recommended.

Heat Treatment:

2507 should be solution annealed and quenched after hot or cold forming solution annealing should be done at a minimum of 19250F. (1025 - 1125 centigrade) Annealing should be followed immediately by a rapid air or water quench to obtain maximum corrosion resistance, heat treated products should be pickled and rinsed.

Welding:

2507 possesses good weldability and can be joined to itself or other materials by shielded metal arc welding, gas tungsten arc welding, plasma arc welding, flux cored wire or submerged arc welding. 2507/P100 filler metal is suggested when welding 2507 because it will produce the appropriate duplex weld structure.

What is ASTM A790 uns S31803 material?

STM A790 UNS S31803 is a specification in duplex steel material. The material is an alloy of steel with chromium and molybdenum in it. The addition of these materials makes the pipes stronger and much corrosion resistant. The SA 790 UNS S31803 one of the super duplex grades which is stronger and corrosion resistant.What is a material equivalent to uns S31803?

S31803 is a duplex stainless steel based on a chromium content of 22% and can also be referenced as DIN 1.4462 and ASTM A182 F51 when supplied as round bar.Is S31803 the same as 2205?

Duplex S31803, also known as stainless steel grade 2205, is a standardized formulation that conforms to UNS specification regulations. Its temperature range is typically listed as -50° to 300° C (-58° to 572° F); outside of this range, its performance characteristics degrade.Material Standards And Grades ASTM A790 UNS S31803 Pipe

| ASTM Specification | ASTM A790/ASME SA790 |

|---|---|

| Standard | NF, JIS, GB, EN, AISI, ASTM, TOCT, SAE, DTD, DS, ASME, DIN, AMS, |

| Size of ASTM A790 UNS S31803 Seamless Pipe | Wall thickness.: 0.05- 20 milimeter, 4 - 219 milimeter |

| Size of Welded Pipe | 5.0 to 1219.02 milimeter |

| size of ASTM A790 UNS S31803 EFW Pipe | 5.0 to 1219.02 milimeter |

| Seamless Tube Size | 3.35 milimeter To 101.6 milimeter OD |

| ASTM A790 UNS S31803 Welded Tube Size | 6.35 milimeter To 152 milimeter OD |

| Bwg & Swg | 18 Swg., 14 20 Swg., Swg. Swg., 12 16 Swg., 10 Swg. |

| ASTM A790 UNS S31803 Tubing wall thickness | 0.020″ -0.220″, (custom wall thicknesses available) |

| Pipe Schedule | SCH20, SCH40S, SCH80, SCH10, SCH60, SCH40, XXS, XS, STD, SCH120, SCH140, SCH80, SCH5, SCH10S, SCH160, SCH30 |

| Length | Standard & Cut length , Single Random, Double Random Pipe |

| Finish | AP (Annealed & Pickled), BA (Bright & Annealed), NO.1, 2B, Polished, MF, HL, NO.4, Mirror finish, BA, 8K etc |

| End | Plain End, Beveled End, Treaded Pipe, Screwed ends |

| Form | Hydraulic, Rectangular, Coiled, Square, Hollow, Round, Straight Pipes/tubes, "U" Shape, Pan Cake Coils, Boiler, LSAWetc. |

| Application | Dairy Pipe, Oil Pipe/tube, Gas Pipe/tube, Fluid Pipe/tube, Boiler Tube, Heat exchanger Tube |

| Type | Seamless /ERW/ EFW / Welded / Fabricated /CDW /DOM/CEW ASTM A790 UNS S31803 Pipe |

| Marking | Heat No. (Or as per need.), Thickness, OD, Grade, Standard Length |

| Value Added Service | Expansion and Draw as per needed Length and Size, , Polish (Comilimeterercial and Electro), Machining, Annealed & Pickled Bending Etc. |

| Specialize in | Large Diameter ASTM A790 UNS S31803 PipeNickel NW 2200 Capillary Tube & Other Odd Size Duplex S31803 Heat Exchanger & Condenser Tube |

| Suppliers of | Sanyo Special Steel, JapanSumitomo Metals, JapanKobe Special Tube, JapanSeah Steel Corporation, KoreaSchoeller Bleckmann, AustriaTubacex Tubos Inoxidables S.A., SpainNippon Steel Corporation, Japan |

| Test Certificate | Under Third Party InspectionManufacturer Test Certificate |

| ASTM A790 UNS S31803 manufacturing Technique | Cold drawn, hot drawn, bright annealed, solid solution, hot extruding |

| Our stockyard | Pimpri-Chinchwad, New Delhi, Abu Dhabi,Tehran, Jamshedpur, Muscat, Gurgaon, Calgary, Ahvaz, India, Bogota, Karachi, Perth, Bangalore, Baroda, Kuwait, Ludhiana, Manama, London, Rajkot, Ahmedabad, Istanbul, Ankara, Khobar, Mexico, Kanpur, Chennai, Ranchi, Howrah, Bengaluru, Courbevoie, Montreal, Gujarat, Damilimeteram, Ernakulam, Noida, Thiruvananthapuram, Tau, Lagos, Santiago, Melbourne, Surat, Kolkata, Hyderabad, Riyadh, Coimbatore, Mumbai, Nagpur, Indore, Caracas, Janeiro, Vadodara, Sydney, Gimhae-si, Port-of-Spain, |