Basic Info.

Packaging & Delivery

Product Description

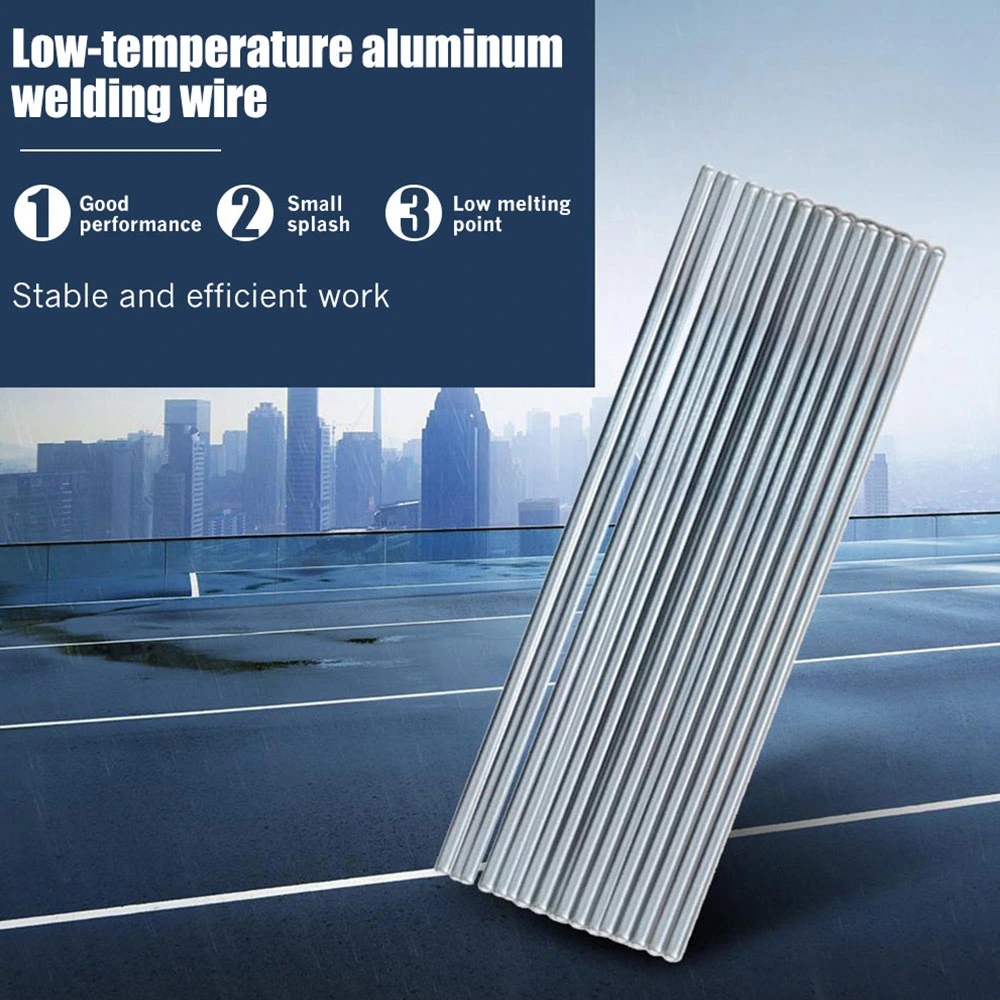

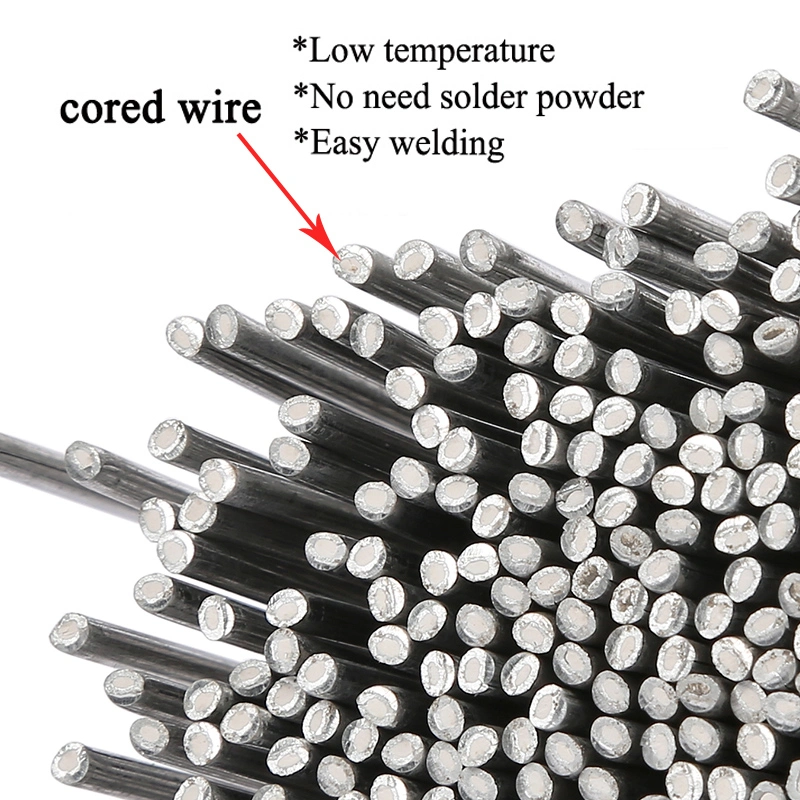

Aluminum flux cored welding wire

Low-temperature aluminum welding wire can weld almost all white metals, including aluminum, aluminum alloy, cast aluminum, aluminum-magnesium alloy and dissimilar welding between the above metals, even for white metals that have been severely corroded or contaminated by oil, even those that are considered irreparable Aluminum alloy can be repaired. Suitable for all-round welding by primary welding operators, only a small heating device is needed. The strength of the weld after welding is generally higher than the strength of the base metal itself. It is enough to know the gas welding operation.

Instructions for use of low temperature aluminum welding wire

One step: through physical cleaning, polish the surface.

Step 2: Heat the surface of the base metal at the welding place until the temperature reaches the working temperature of the welding wire 380ºC-400ºC, so that the welding wire can be melted to form a weld by the heat conduction of the base metal. Do not use flame to burn the welding wire. When the surface temperature of the material is sufficient, the welding wire can flow and penetrate into the metal capillary well.

Three steps: When repairing thinner aluminum, just heat the aluminum base material to a suitable working temperature, and then use the welding wire to friction and fuse to form a weld. Only use a metal brush to fill the weld with the molten wire to form a weld.