Basic Info.

Model NO.

AWS A5.36 E71T-1

Specification

0.6-2.0mm

Trademark

WELDBST

Origin

China

HS Code

83112000

Production Capacity

50000tons/Year

Product Description

Product Discription:

HFX-E71T-1 is a titania type CO2 gas shielded flux cored welding wire for low carbon steel and 490 MPa high strength steel. It has excellent welding performance, soft and stable arc, fewer spatters, good slag detachability and beautiful appearance of weld. Suitable for downhand welding and horizontal welding. All-position welding. It has high welding efficiency. The weld metal has been given toughening treatment by microelements, so it has excellent low temperature toughness, good crack resistance, stable and reliable inherent quality.

Model No.: HFX-E71T-1C / 1M

Flux contanining: Containing flux

Gas: Required

Diameter: 0.6mm, 0.8mm, 0.9mm, 1.0 mm, 1.1mm, 1.2 mm, 1.4mm, 1.6 mm, 2.0mm

Type: Rolling

Weight: 1kg, 4kg, 5kg, 15 kg per spool, 200 kgs per drum.

Export markets: Global

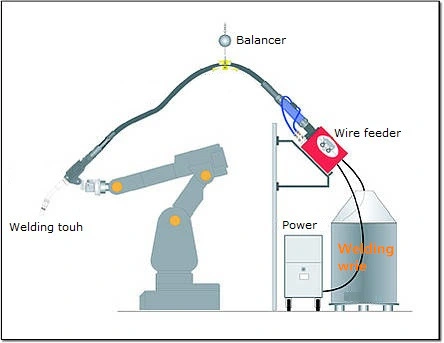

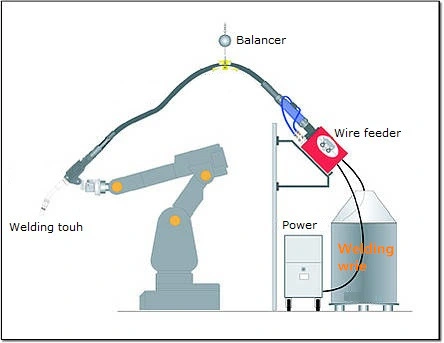

Application:

Used for welding structures made of carbon steel and low alloy structural steel with tensile strength higher than or equal to 490MPa. Most widely used for welding some key structures like shipbuilding, mechanical manufacture, pressure vessels, boilers, petroleum machinery, chemical machinery, hoisting machinery etc..

Chemical composition of wires (%)

Typical mechanical properties of deposited metal

Welding Parameters : DC(+) CO2 gas

Quality Approval: CCS, DNV, GL, LR, ABS, BV, NK, RINA, KR, RS

Application

Application

Our services

1. Free sample is available

2. OEM service is available

3. High quality and professional service.

4. Much more competitive price.

5. On-time delivery

FAQ

1. Can you provide free sample for quality testing?

-Yes, we can provide few quantity on free base.

2. Do you accept small order ?

-Yes.

3. Do you accept OEM ?

- Yes, we accept OEM packing on FCL base.

4. Do you accept mix items in one container ?

- Yes.

5. Do you have inspection procedures for product?

- Yes, we have Mill Test Report with each shipment

HFX-E71T-1 is a titania type CO2 gas shielded flux cored welding wire for low carbon steel and 490 MPa high strength steel. It has excellent welding performance, soft and stable arc, fewer spatters, good slag detachability and beautiful appearance of weld. Suitable for downhand welding and horizontal welding. All-position welding. It has high welding efficiency. The weld metal has been given toughening treatment by microelements, so it has excellent low temperature toughness, good crack resistance, stable and reliable inherent quality.

Model No.: HFX-E71T-1C / 1M

Flux contanining: Containing flux

Gas: Required

Diameter: 0.6mm, 0.8mm, 0.9mm, 1.0 mm, 1.1mm, 1.2 mm, 1.4mm, 1.6 mm, 2.0mm

Type: Rolling

Weight: 1kg, 4kg, 5kg, 15 kg per spool, 200 kgs per drum.

Export markets: Global

Application:

Used for welding structures made of carbon steel and low alloy structural steel with tensile strength higher than or equal to 490MPa. Most widely used for welding some key structures like shipbuilding, mechanical manufacture, pressure vessels, boilers, petroleum machinery, chemical machinery, hoisting machinery etc..

Chemical composition of wires (%)

| Item | C | Mn | Si | S | P |

| Value | 0.07 | 1.25 | 0.36 | 0.010 | 0.012 |

Typical mechanical properties of deposited metal

| Item | Tensile Strength Rm(Mpa) | Yield Strength REl(Mpa) | Elongation (%) | AKV Impact value (J)(-20°C) |

| Values | 570 | 490 | 28 | 100 |

Welding Parameters : DC(+) CO2 gas

| Wire Diameter(mm) | Welding current(A) | Welding Voltage(V) | Gas Flow(L/min) |

| 0.8 | 50-100 | 18-20 | 15-25 |

| 0.9 | 60-110 | 18-20 | 15-25 |

| 1.0 | 70-120 | 19-21 | 15-25 |

| 1.2 | 140-300 | 20-30 | 15-25 |

| 1.4 | 200-360 | 24-32 | 15-25 |

| 1.6 | 240-380 | 26-34 | 15-25 |

Quality Approval: CCS, DNV, GL, LR, ABS, BV, NK, RINA, KR, RS

Application

Application  |  |  |

|  |  |

1. Free sample is available

2. OEM service is available

3. High quality and professional service.

4. Much more competitive price.

5. On-time delivery

FAQ

1. Can you provide free sample for quality testing?

-Yes, we can provide few quantity on free base.

2. Do you accept small order ?

-Yes.

3. Do you accept OEM ?

- Yes, we accept OEM packing on FCL base.

4. Do you accept mix items in one container ?

- Yes.

5. Do you have inspection procedures for product?

- Yes, we have Mill Test Report with each shipment