Basic Info.

Model NO.

ss420

Surface

bright surface of ss 420

Serves

ss 420 wire small order accepted

Size

in customer′s requirement

Certificate

ISO9001:2009

Transport Package

15kg/Spool, Carton, Wooden Case

Specification

1.6mm, 2.0mm, 3.175mm

Trademark

TANKII

Origin

Shanghai, China

HS Code

7223000000

Production Capacity

2000 Tons/Year

Packaging & Delivery

Package Size

30.00cm * 30.00cm * 15.00cm

Package Gross Weight

15.000kg

Product Description

Thermal Spray Wire Metcoloy 2/ss420 /2Cr13 Metco Stainless Steel Welding Wire

1. Indroduction

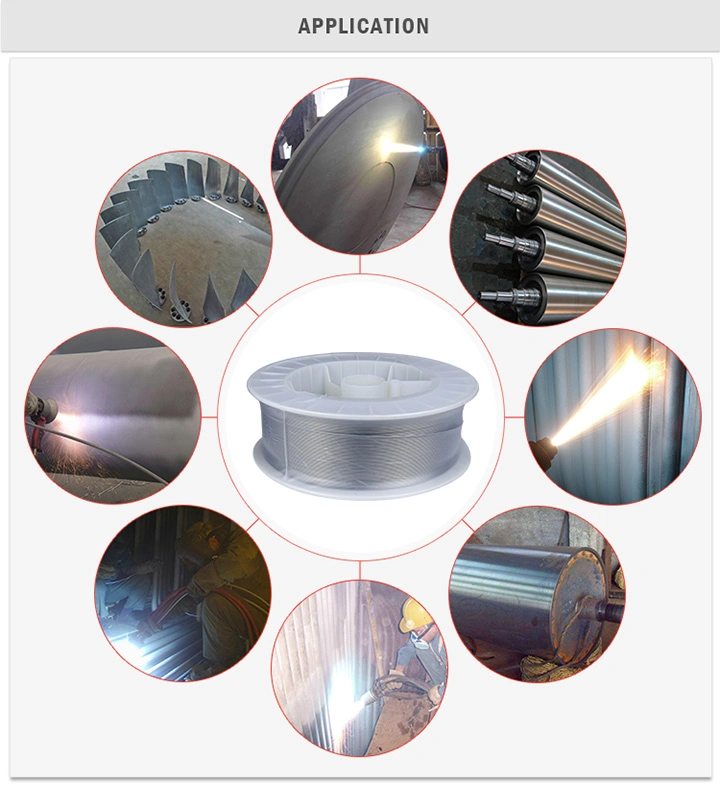

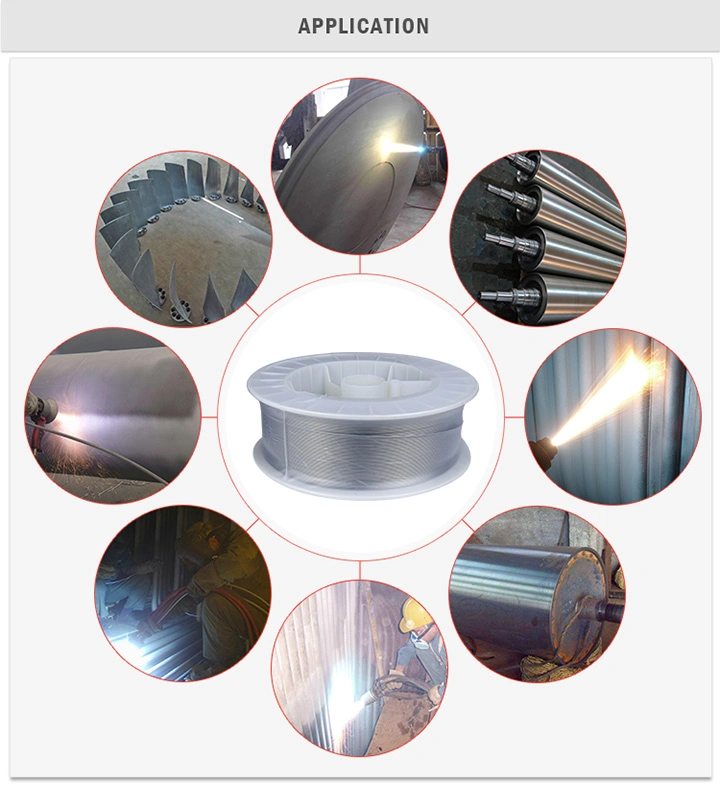

TANKII 420 stainless steel wire, specifically designed for arc spray processes. 420 SS forms a dense, well bonded coating, with excellent wear resistance and good corrosion resistance. It is widely used for machine elements repair, dimensional restoration, and wear resistant application. 420 SS's low shrink rate characteristics allows for increased coating thickness on parts requiring heavier coatings.

2.Chemical Composition of SS 420 thermal spray wire, %

3. Mechanical Properties of SS 420 thermal spray wire

1. Indroduction

TANKII 420 stainless steel wire, specifically designed for arc spray processes. 420 SS forms a dense, well bonded coating, with excellent wear resistance and good corrosion resistance. It is widely used for machine elements repair, dimensional restoration, and wear resistant application. 420 SS's low shrink rate characteristics allows for increased coating thickness on parts requiring heavier coatings.

2.Chemical Composition of SS 420 thermal spray wire, %

| Cr | Si | Mn | C | Fe |

| 13.0 | 1.0 | 1.0 | 0.3 | Bal |

3. Mechanical Properties of SS 420 thermal spray wire

| Coating Hardness | HRC 40-45 |

| Bonding Strength | 48.95 N/mm2 |

| Deposit Rate | 10 lbs/hr/100A |

| Service Temperature | Up to 550C 1022F |

| Condition | Solid Wire |

| Diameter | 1.6mm(14 ga),2.0mm,3.175mm |

| Package Size | 10kg,15kg,or up to client's demand |

| Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel 500 | HC-276 | Cr20Ni80 |

| C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

| Fe | ≤1.0 | N/A | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | N/A |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

| Cu | N/A | N/A | N/A | rest | 27-33 | N/A | N/A |

| Ni | rest | rest | rest | 65-67 | rest | rest | rest |

| Co | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| Al | ≤0.4 | 4-5 | N/A | ≤0.5 | 2.3-3.15 | N/A | N/A |

| Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | N/A | N/A |

| Cr | 21.5-23 | ≤0.2 | 42-46 | N/A | N/A | 14.5-16 | 20-23 |

| Nb | 3.5-4.15 | N/A | N/A | N/A | N/A | N/A | ≤1.0 |

| Mo | 8.5-10 | N/A | N/A | N/A | N/A | 15-17 | N/A |

| V | N/A | N/A | N/A | N/A | N/A | ≤0.35 | N/A |

| W | N/A | N/A | N/A | N/A | N/A | 3.0-4.5 | N/A |

| Impurities | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |