Basic Info.

Model NO.

SJ301

Application

Submerged-arc Welding

Manufacturing Method

Smelting

Grain Size

10-60mesh

Packaging Details

25kg Welding Flux /Kraft Paper Bag, 40 Bags/Pallet

Transport Package

Kraft Bag with Plastic Lining Inside

Specification

25kg/bag, 40bags/wooden pallet

Trademark

Panding

Origin

Laiwu City, Shandong Province, China

HS Code

381090000

Production Capacity

10000 Tons Agglomerated Flux, 8000 Tons Fused Flux

Product Description

Submerged Arc Welding Flux Manufacturer LaiWu HuLin Welding

SJ301 TECHNICAL DATA

1)Specifications:

AWS-A5.17 F6A0-EL8 F7A2-EM12K EN760 SA CS 1 89 AC H5

2)Description:

SJ301 is an agglomerated calcium-silicate type welding flux. Basicity: 1.0 (B//W) It is gray and round grain, mesh: 10-40. Regularly shaped welds are deposited without reduction of area or interface notches. Slag detachability is good. A short slag is produced, thus allowing circumferential welding on small-diameter workpieces without the risk of uncontrolled slag. The production of large pipes(especially spiral pipe welding) is a typical application for this flux. Relatively high manganese pick-up is obtained, thus allowing the flux to be used with wires with a low Mn content.

3)Caution:

It should be re-dried under 300-350ºC for 2 hours. Rust, grease and moisture on the weldment should be removed before welding.

4) Applications:

The flux is fit for the submerge-arc welding of low-carbon steel and low-alloy steel. Butt and flat fillet welding of miniature LPG tanks pipeline steel, , ships, vehicles, agricultural implements, machinery, boilers, bridges, structural steels.

5)Chemical Composition(%)

6)Mechanical Performance of the Deposited Metal

Application:

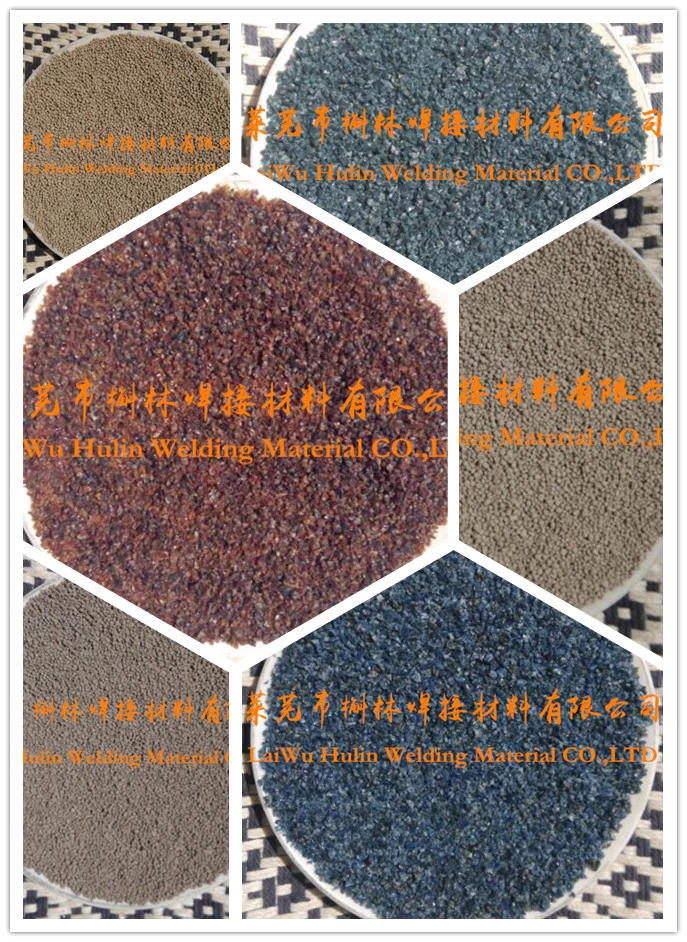

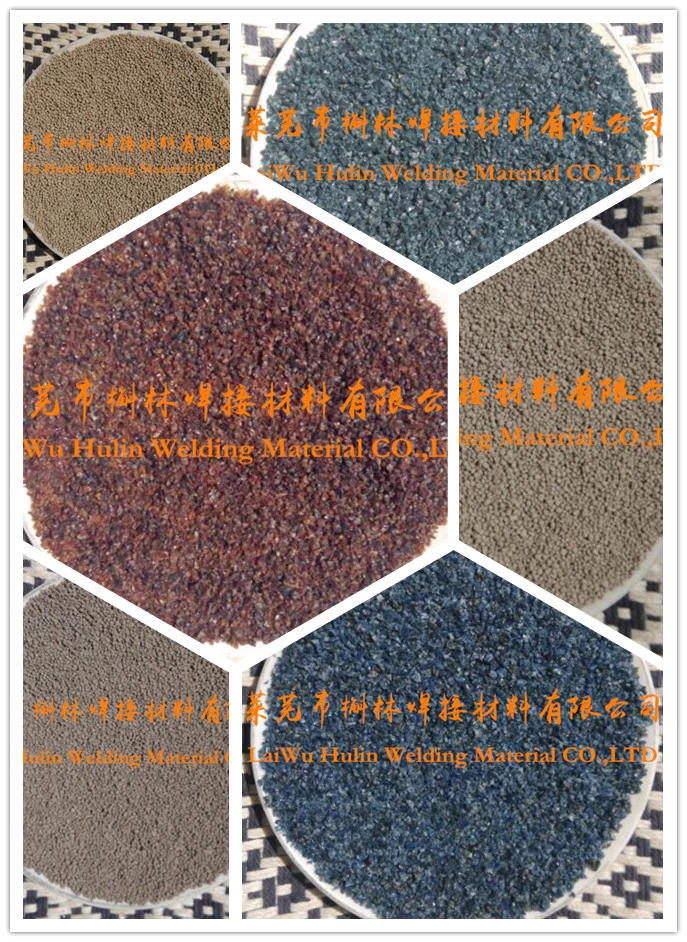

Product Picture

Company Brief Introduction

(1)Company Name:LaiWu HuLin Welding Material Co.,Ltd

(2)Company Website:hlweldingflux.en.made-in-china.com

(3)Main Products:

Submerged Arc Welding Flux

Welding Wire

(4)Best Selling Product Models:

Welding Flux:SJ101,SJ101G,SJ102,SJ301,SJ501,HJ107,HJ260,HJ431

Welding Wire:ER70S-6

(5)Quality System:ISO9001:2000

(6)Year Established:1999

(7)Brand Name:Panding Brand

(8)Annual Capacity:12000 metric tons of agglomerated flux

10000 metric tons of fused flux

Packing & Shipping Details:

(1)Bag:25 KGS/Kraft Bag With Plastic Lining Inside

(2)Pallet:40 Bags(1 Ton)/Plywood Pallet

(3)Container:20-24 Tons/Container

(4)OEM Packing Design Can Be Accept According To Your Requirement

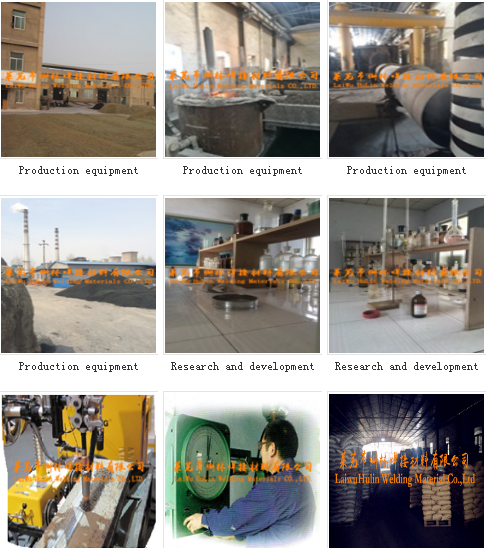

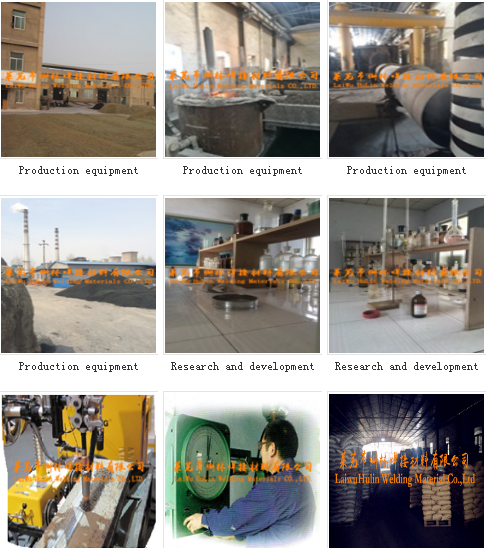

Facrory Workshop & Production Line

FAQ:

1)Are you a factory or a trading company?

LaiWu HuLin Welding Materials Co., Ltd. is a professional factory of welding wire&welding flux, at the same time, we have own professional marketing team to expand the overseas market.

2)Is OEM available?

Yes, OEM is available.

3)Is the sample available?

Yes, free samples are available for you to test the quality.

4)Have the products been tested before shipping?

Yes, of course, all of our welding products would have been tested before shipping on board.

The Mill Test Certificate can be provided by our professional test Lab.

5)What's benefit will you bring?

Your clients will be satisfied with the quality and service.You can enjoy high reputation from your markets and obtain more orders.

6)What about the price terms?

CIF, CFR, FOB

7)How about the payment terms?

ONE:30% T/T in advance, 70% balance against B/L copy.

TWO:L/C at sight.

8)What about the lead/shipping time?

Within 5~25 Days After Receipt Of Payment.

9)What is the MOQ?

20-25 Tons For One Full 20ft Container Load.

10)What about the package?

Forward Welding Package/Neutral Package/OEM Package

CONTCT US

SJ301 TECHNICAL DATA

1)Specifications:

AWS-A5.17 F6A0-EL8 F7A2-EM12K EN760 SA CS 1 89 AC H5

2)Description:

SJ301 is an agglomerated calcium-silicate type welding flux. Basicity: 1.0 (B//W) It is gray and round grain, mesh: 10-40. Regularly shaped welds are deposited without reduction of area or interface notches. Slag detachability is good. A short slag is produced, thus allowing circumferential welding on small-diameter workpieces without the risk of uncontrolled slag. The production of large pipes(especially spiral pipe welding) is a typical application for this flux. Relatively high manganese pick-up is obtained, thus allowing the flux to be used with wires with a low Mn content.

3)Caution:

It should be re-dried under 300-350ºC for 2 hours. Rust, grease and moisture on the weldment should be removed before welding.

4) Applications:

The flux is fit for the submerge-arc welding of low-carbon steel and low-alloy steel. Butt and flat fillet welding of miniature LPG tanks pipeline steel, , ships, vehicles, agricultural implements, machinery, boilers, bridges, structural steels.

5)Chemical Composition(%)

| SiO2+TiO2 | Al2O3+MnO | CaO+MGO | CaF2 | S | P |

| 25-35 | 30-40 | 15-25 | 5-15 | ≤0.05 | ≤0.05 |

Wires | Standard Models | Yield Point Rel(MPa) | Tensile Strength RM(MPa) | Elongation A (%) | Impact Value Kv2(J) |

| EL8 EM12K | F6A0-EL8 F7A2-EM12K | ≥350 ≥410 | 415-550 480-650 | ≥22 ≥30 | ≥40(0ºC) ≥60(-20ºC) |

Application:

Product Picture

Company Brief Introduction

(1)Company Name:LaiWu HuLin Welding Material Co.,Ltd

(2)Company Website:hlweldingflux.en.made-in-china.com

(3)Main Products:

Submerged Arc Welding Flux

Welding Wire

(4)Best Selling Product Models:

Welding Flux:SJ101,SJ101G,SJ102,SJ301,SJ501,HJ107,HJ260,HJ431

Welding Wire:ER70S-6

(5)Quality System:ISO9001:2000

(6)Year Established:1999

(7)Brand Name:Panding Brand

(8)Annual Capacity:12000 metric tons of agglomerated flux

10000 metric tons of fused flux

Packing & Shipping Details:

(1)Bag:25 KGS/Kraft Bag With Plastic Lining Inside

(2)Pallet:40 Bags(1 Ton)/Plywood Pallet

(3)Container:20-24 Tons/Container

(4)OEM Packing Design Can Be Accept According To Your Requirement

Facrory Workshop & Production Line

FAQ:

1)Are you a factory or a trading company?

LaiWu HuLin Welding Materials Co., Ltd. is a professional factory of welding wire&welding flux, at the same time, we have own professional marketing team to expand the overseas market.

2)Is OEM available?

Yes, OEM is available.

3)Is the sample available?

Yes, free samples are available for you to test the quality.

4)Have the products been tested before shipping?

Yes, of course, all of our welding products would have been tested before shipping on board.

The Mill Test Certificate can be provided by our professional test Lab.

5)What's benefit will you bring?

Your clients will be satisfied with the quality and service.You can enjoy high reputation from your markets and obtain more orders.

6)What about the price terms?

CIF, CFR, FOB

7)How about the payment terms?

ONE:30% T/T in advance, 70% balance against B/L copy.

TWO:L/C at sight.

8)What about the lead/shipping time?

Within 5~25 Days After Receipt Of Payment.

9)What is the MOQ?

20-25 Tons For One Full 20ft Container Load.

10)What about the package?

Forward Welding Package/Neutral Package/OEM Package

CONTCT US