Basic Info.

Model NO.

E308-16, E308L-16, E309-16, E309L-16

Length

300-400cm

Welding Core Type

Stainless Steel

Electrode Coating Type

Titanium Calcium

Slag Characteristic

Acidic

Stainless Steel Welding Rod Type

Chromium Stainless Steel

Function

Low Hydrogen Type Electrode, Gravity Electrode, Moisture-Proof Electrode

Welding Power

AC/DC

Transport Package

Carton

Specification

5kgs/inner box, 20kgs/outer carton

Trademark

TYUE

Origin

China

HS Code

8311100000

Production Capacity

500000000ton/Year

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 120.00cm

Package Gross Weight

1050.000kg

Product Description

Product Description

E308L-16 Stainless Steel Welding Electrode/Rod

Description:

A002 is a super-low carbon Cr19Ni10 stainless steel type electrode coated with Titanium-calcium.The molten content is ≤0.04%.It provides excellent performance of intorcry stalline corrosion resistance.It has excellent operational technological performace on both AC and DC.

Application:

It applies to welding the structure of super-low carbon Cr19Ni10 stainless steel.It also suitable for welding the structure of anti-corrosion stainess steel 0Cr19NillT1 which working temperature below 300ºC.It is mainly used for equipment manufacturing of fibre,fertilizer and petroleum industry.

Notes:

1.Electrodes must be baked for 1 hour at 150ºC before welding operation.

2.To operate on DC if all possible.Operate with small current so the electrode will not in red-hot.

3.The anti-corrosion performance and ferrite composition should be detemined between buyer and seller

A002 is a super-low carbon Cr19Ni10 stainless steel type electrode coated with Titanium-calcium.The molten content is ≤0.04%.It provides excellent performance of intorcry stalline corrosion resistance.It has excellent operational technological performace on both AC and DC.

Application:

It applies to welding the structure of super-low carbon Cr19Ni10 stainless steel.It also suitable for welding the structure of anti-corrosion stainess steel 0Cr19NillT1 which working temperature below 300ºC.It is mainly used for equipment manufacturing of fibre,fertilizer and petroleum industry.

| Chemical Composition Deposited Metal (%) | ||||||||

| C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| ≤0.04 | 0.5~2.5 | ≤0.90 | ≤18~21 | 9~11 | ≤0.03 | ≤0.04 | ≤0.75 | ≤0.75 |

| Mechanical Properties of Deposited metal | ||||||||

| Test Item | Tensile Strength ós (Mpa) | Elongation δ5(%) | ||||||

| Guranteed | ≥520 | ≥35 | ||||||

| Sizes & Recommended Current (AC or DC) | |||||

| Welding rod diameter (mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 |

| welding current (A) | 25~50 | 50~80 | 80~110 | 110~160 | 160~200 |

Notes:

1.Electrodes must be baked for 1 hour at 150ºC before welding operation.

2.To operate on DC if all possible.Operate with small current so the electrode will not in red-hot.

3.The anti-corrosion performance and ferrite composition should be detemined between buyer and seller

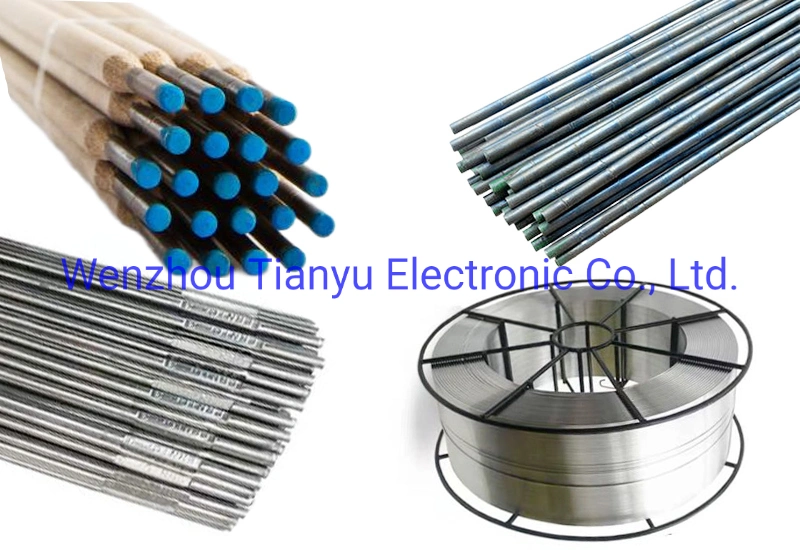

-------------------Our Other Welding Products-------------------

If you are interested, please click on the below picture to enter the link