- Overview

- Product Description

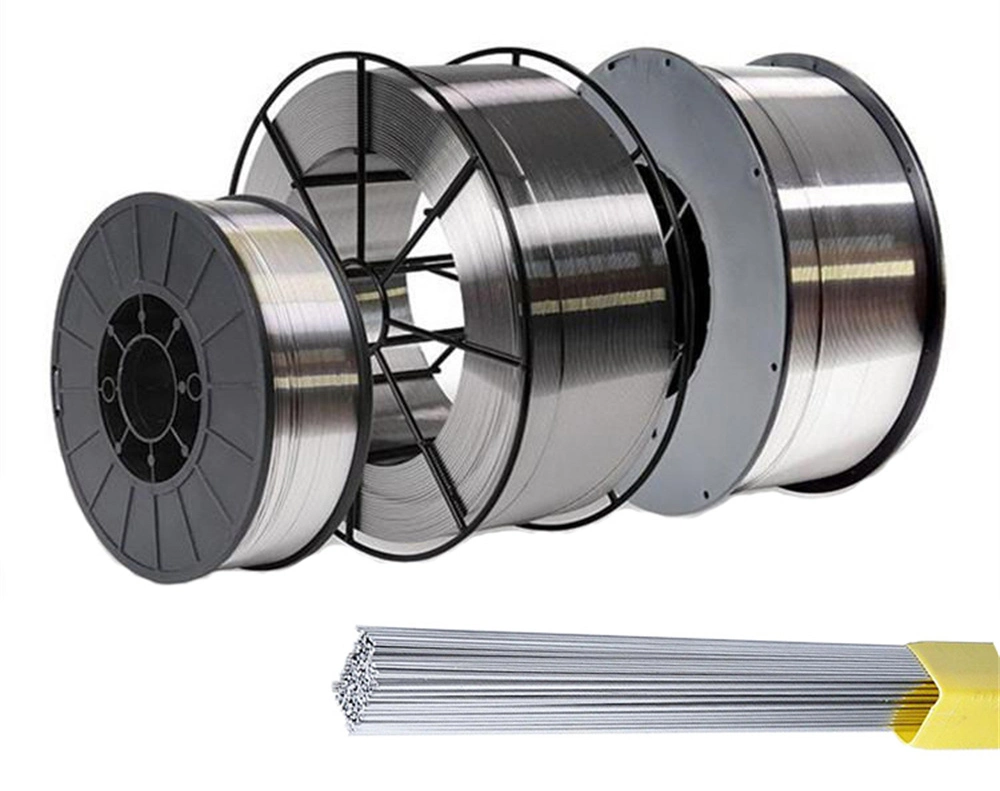

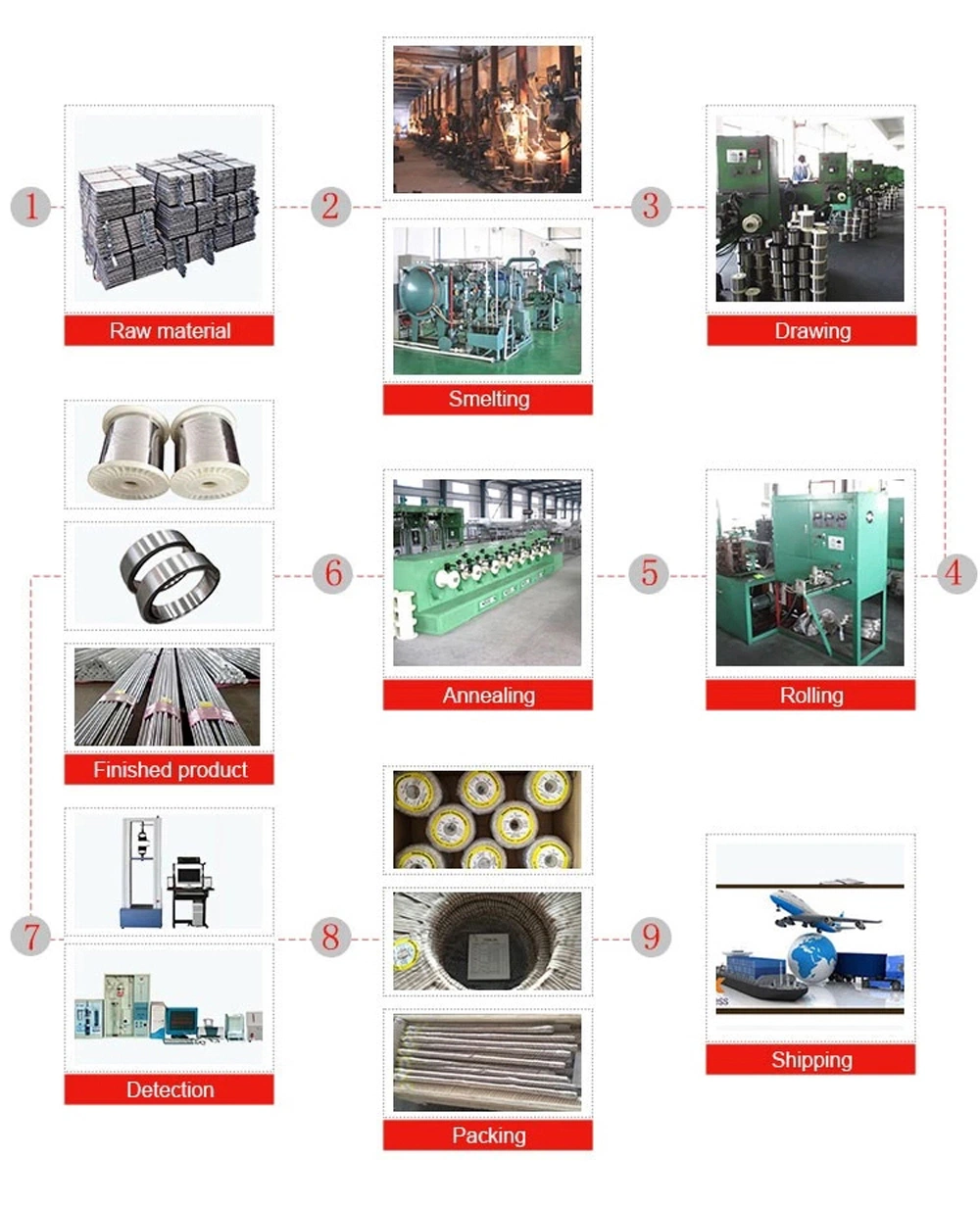

- Detailed Photos

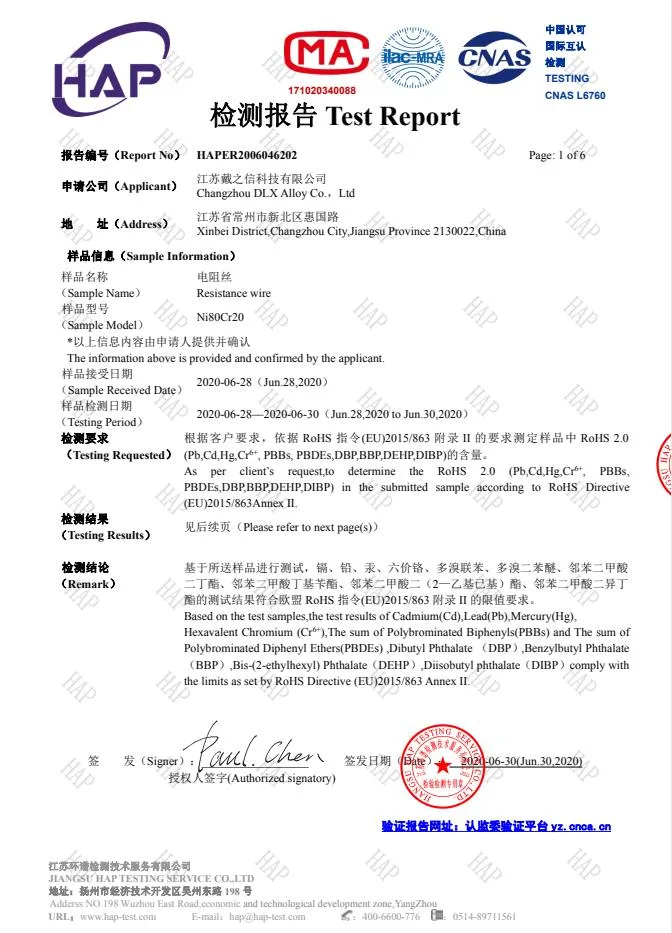

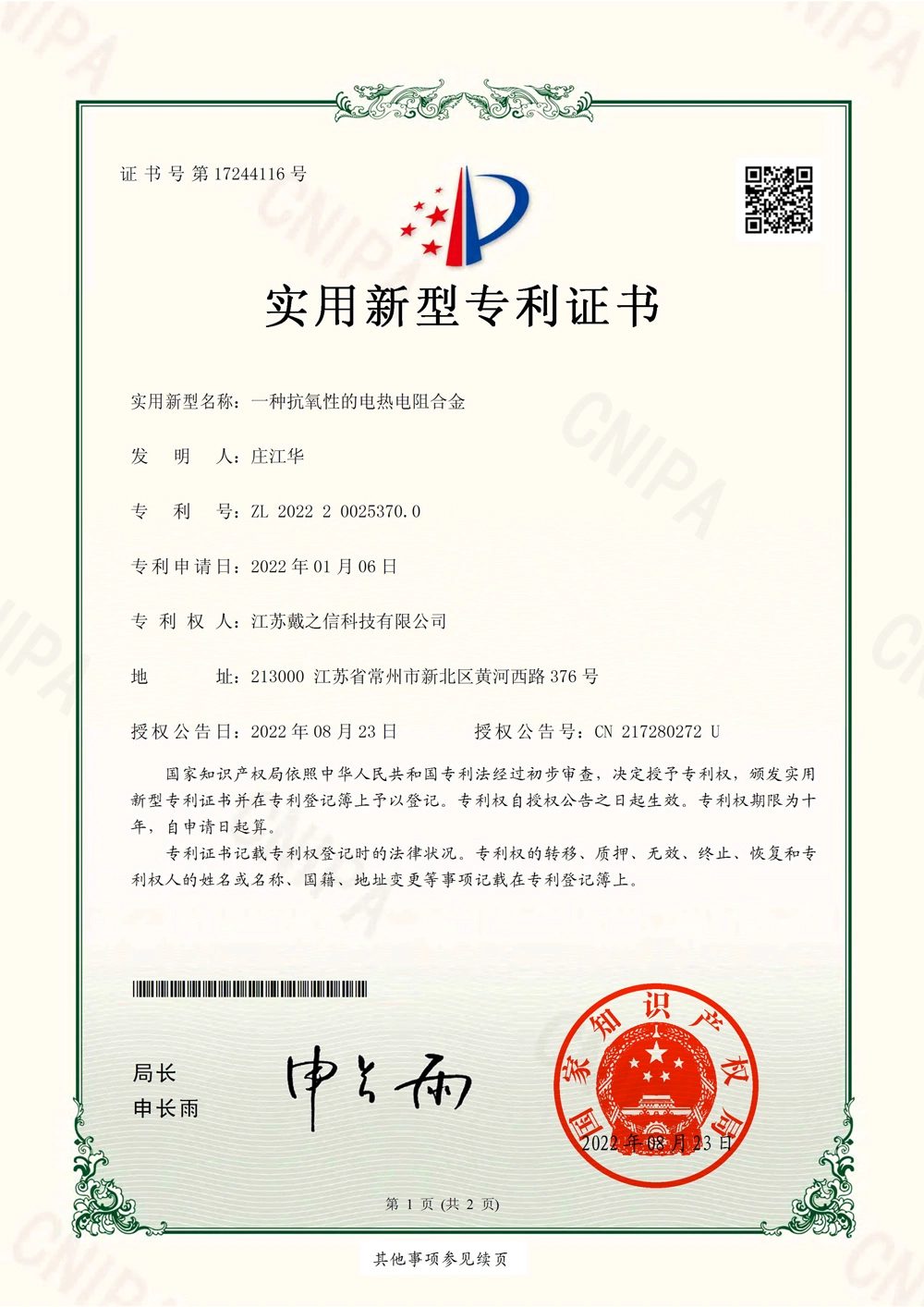

- Certifications

- Company Profile

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

According to the definition of GB/T20878-2007, Stainless Steel is a steel whose main characteristics are stainless and corrosion resistance, with a chromium content of at least 10.5% and a carbon content of no more than 1.2%.

Stainless steel is often divided into martensitic steel, ferritic steel, austenitic steel, austenitic-ferritic (duplex) stainless steel and precipitation hardening stainless steel according to the organizational state. In addition, it can be divided into: chromium stainless steel, chromium-nickel stainless steel and chromium manganese nitrogen stainless steel.

200 Series: Chromium-Manganese-Nickel

201, 202, etc.: Nickel is replaced by manganese, which has poor corrosion resistance and is widely used as a cheap substitute for 300 series in China

300 series: chromium-nickel austenitic stainless steel

301: Good ductility, used for molding products. It can also be hardened by mechanical processing. Good weldability. Wear resistance and fatigue strength are better than 304 stainless steel.

302: The corrosion resistance is the same as that of 304, and the strength is better due to the relatively high carbon content.

303: By adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

304: General model; that is, 18/8 stainless steel. Products such as: corrosion-resistant containers, tableware, furniture, railings, medical equipment. The standard composition is 18 % chromium plus 8 % nickel. It is a stainless steel that is non-magnetic and cannot change its metallographic structure by heat treatment. The GB grade is 06Cr19Ni10.

304 L: The same characteristics as 304, but low carbon so it is more corrosion resistant, easy to heat treatment, but poor in mechanical properties, suitable for welding and products that are not easy to heat treatment.

304 N: It has the same characteristics as 304. It is a nitrogen-containing stainless steel. Nitrogen is added to increase the strength of the steel.

309: Compared with 304, it has better temperature resistance, and the temperature resistance is as high as 980 °C.

309 S: It has a lot of chromium and nickel, so it has good heat resistance and oxidation resistance. Products such as: heat exchangers, boiler components, and jet engines.

310: Excellent high temperature oxidation resistance, the maximum service temperature is 1200°C.

316: After 304, the second most widely used steel grade is mainly used in the food industry, watch accessories, pharmaceutical industry and surgical equipment. Adding molybdenum element makes it obtain a special corrosion-resistant structure. Because it has better resistance to chloride corrosion than 304, it is also used as "marine steel". SS316 is usually used in nuclear fuel recovery units. Grade 18/10 stainless steel is also generally suitable for this application level.

316 L: Low carbon, so it is more corrosion-resistant and easy to heat treatment. Products such as: chemical processing equipment, nuclear power generators, and refrigerant storage tanks.

321: In addition to reducing the risk of material weld corrosion due to the addition of titanium, other properties are similar to 304.

347: Add the stabilizing element niobium, suitable for welding aircraft parts and chemical equipment.

400 series: Ferritic and martensitic stainless steel, manganese-free, can replace 304 stainless steel to a certain extent

408: Good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni.

409: The cheapest model (British and American), usually used as a car exhaust pipe, is a ferritic stainless steel (chrome steel).

410: Martensitic (high-strength chromium steel), good wear resistance and poor corrosion resistance.

416: The addition of sulfur improves the processing properties of the material.

420: "Knife grade" martensitic steel, similar to the earliest stainless steels such as Brinell high chromium steels. It is also used for surgical knives and can be made very shiny.

430: Ferritic stainless steel, for decoration, such as for automotive accessories. Good formability, but poor temperature resistance and corrosion resistance.

440: High-strength cutting tool steel with slightly higher carbon content. After proper heat treatment, a higher yield strength can be obtained, and the hardness can reach 58HRC. It is among the hardest stainless steels. The most common application example is "razor blades". There are three commonly used models: 440A, 440B, 440C, and 440F (easy to process).

500 series: heat resistant chromium alloy steel.

600 series: martensitic precipitation hardening stainless steel.

| AISI | chemical component(%) | |||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Ti | |

| 304 | <0.08 | <1.0 | <2.0 | <0.035 | <0.03 | 8~10 | 17~19 | - | - | - |

| 304L | <0.03 | <1.0 | <2.0 | <0.04 | <0.03 | 9~13 | 18~20 | - | - | - |

| 304HC | <0.06 | <1.0 | 1.2-1.8 | <0.035 | <0.03 | 8~11 | 17~19 | - | 2.0-3.0 | - |

| 316 | <0.08 | <1.0 | <2.0 | <0.04 | <0.03 | 10~14 | 16~18 | 2.0~3.0 | - | - |

| 316L | <0.03 | <1.0 | <2.0 | <0.04 | <0.03 | 12~15 | 16~18 | 2.0~3.0 | - | - |

| 310S | <0.08 | <1.5 | <2.0 | <0.04 | <0.03 | 19~22 | 24~26 | - | - | - |

| 321 | <0.08 | <1.0 | <2.0 | <0.045 | <0.03 | 9~13 | 17~19 | - | - | >0.035 |

| 301 | <0.15 | <1.0 | <2.0 | <0.04 | <0.03 | >7 | 16~18 | - | - | - |

| 302 | <0.15 | <1.0 | <2.0 | <0.04 | <0.03 | >8 | 17~19 | - | - | - |

| Chemical Compositions of Stainless Steel Welding Wire: | |||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | |

| 304 | 0.08 | 0.30-1.00 | 2 | 0.045 | 0.03 | 18.00-20.00 | 8.00-11.00 | 0.18 | 0.003 |

| 304L | 0.03 | 0.30-1.00 | 2 | 0.045 | 0.03 | 18.00-20.00 | 8.00-12.00 | ||

| ER307 | 0.04-0.14 | 0.30-0.65 | 4.30-4.75 | 0.03 | 0.03 | 19.50-22.00 | 8.00-10.70 | 0.5-1.5 | 0.75 |

| ER308 | 0.08 | 0.30-0.65 | 4.30-4.75 | 0.03 | 0.03 | 19.50-22.00 | 9.00-11.00 | 0.75 | 0.75 |

| ER308L | 0.03 | 0.30-0.65 | 1.50-2.30 | 0.03 | 0.02 | 19.5-21.5 | 9.00-11.00 | 0.75 | 0.75 |

| ER308LSi | 0.03 | 0.65-1.00 | 1.60-2.40 | 0.03 | 0.02 | 19.5-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER309 | 0.12 | 0.30-0.65 | 1.00-2.50 | 0.03 | 0.03 | 24.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER316 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 18.00-12.00 | 11.0-14.0 | 2.0-3.0 | 0.75 |

| ER316L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER316LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER310 | 0.08-0.15 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.75 |

| ER347 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 19.0-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER317 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.01 | 18.5-20.5 | 13.0-15.0 | 3.0-4.0 | 0.75 |

| ER321 | 0.08 | 0.3-0.65 | 1.5-2.5 | 0.03 | 0.01 | 18.5-20.5 | 9.0-10.5 | 0.75 | 0.75 |

heat resistance

In intermittent use below 1600 degrees and continuous use below 1700 degrees, 316 stainless steel has good oxidation resistance. In the range of 800-1575 degrees, it is best not to use 316 stainless steel continuously, but when 316 stainless steel is used continuously outside this temperature range, the stainless steel has good heat resistance. The carbide precipitation resistance of 316L stainless steel is better than that of 316 stainless steel, and the above temperature range can be used.

Corrosion resistance

The corrosion resistance of 316 is better than that of 304 stainless steel, and it has good corrosion resistance in the production process of pulp and paper. Moreover, 316 stainless steel is also resistant to erosion by marine and aggressive industrial atmospheres.

| Mechanical Properties of Welding Wire: | |||

| Tensile strength Rm (Mpa) | Yield strength Rel or Rp0.2(Mpa) | Elongation(%) | |

| 304 | 550 | -- | 25 |

| 304L | 510 | -- | 25 |

| ER307 | 590 | 350 | 25 |

| ER308 | 550 | 350 | 25 |

| ER308L | 510 | 320 | 25 |

| ER308LSi | 510 | 320 | 25 |

| ER309 | 550 | 350 | 25 |

| ER309L | 510 | 320 | 25 |

| ER309LSi | 510 | 320 | 25 |

| ER316 | 510 | 320 | 25 |

| ER316L | 510 | 320 | 25 |

| ER316LSi | 510 | 320 | 20 |

| ER310 | 550 | 350 | 25 |

| ER347 | 550 | 350 | 25 |

| ER317 | 550 | 350 | 25 |

| ER321 | 550 | 350 | 25 |

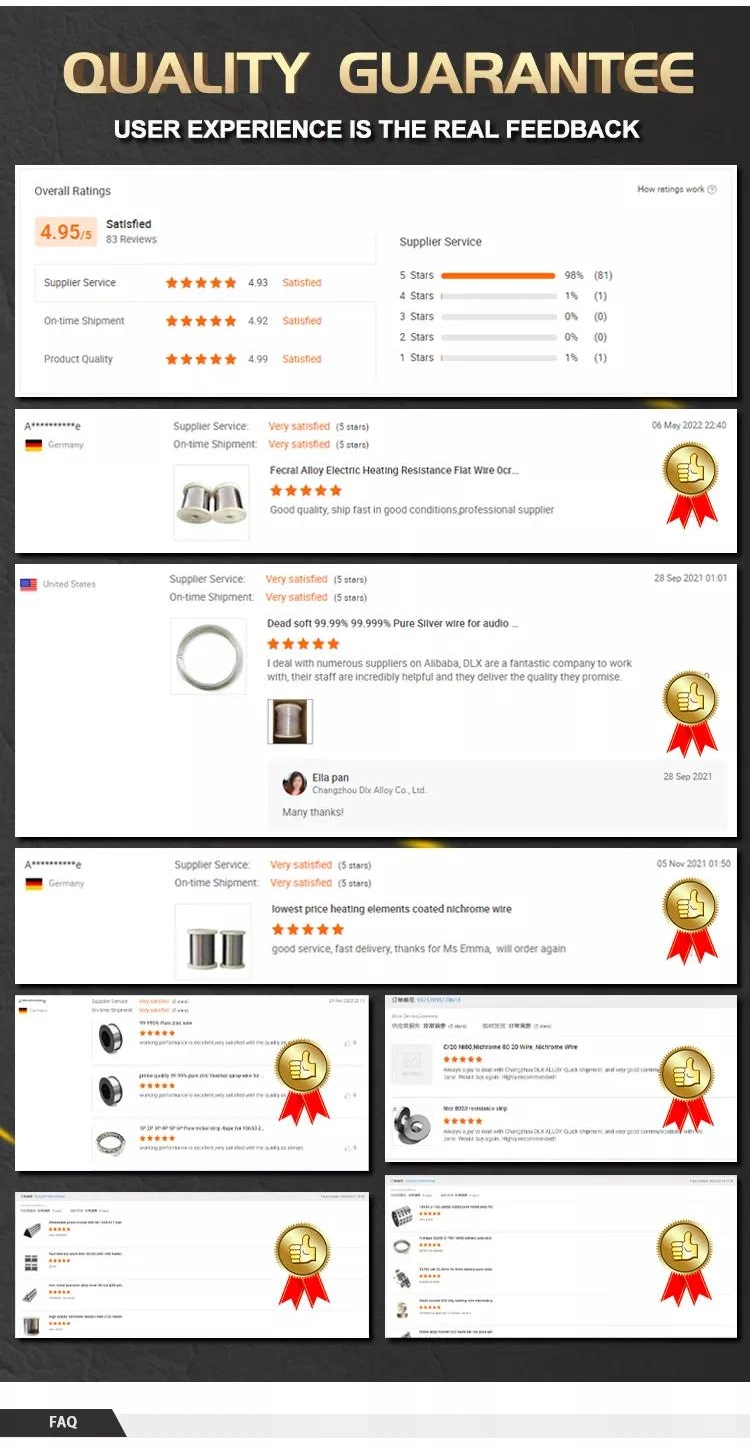

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples.

2, We can provide the products within a week after payment.

3, Wecan provide sample of the products customer need.

4, We always insist on "Quality first, Customer first" as our business philosophy.

Question: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Question: could we visit your factory?

Answer: Sure, factory visit is warmly welcome.