Basic Info.

Model NO.

DTN1

Conductive Way

Both-Sided

Welding Spot Number

Single

Type

Universal

Transport Package

Wooden Case

Specification

880*450*1700(mm)

Trademark

dingjuquanqiu

Origin

China

HS Code

8515809090

Production Capacity

50 Sets/Month

Product Description

DTN Resistance Spot Welding Machine

a )Smaller pollution to power grid.

b)Continuous loop execute multiple welding specification

c) Preheating current, welding current and tempering current

d) used for welding special materials, such as welding aluminum, galvanized metal, etc.

e)automatically shut down the output and prompt the fault reason.

Why Choose Us?

a)12 Patents of welding machine

b)Thousand grade of warehouse, delivery time is guaranteed

c)Profession designer and engineer, assure production quality

d)CCC issued by China Quality Certification Center

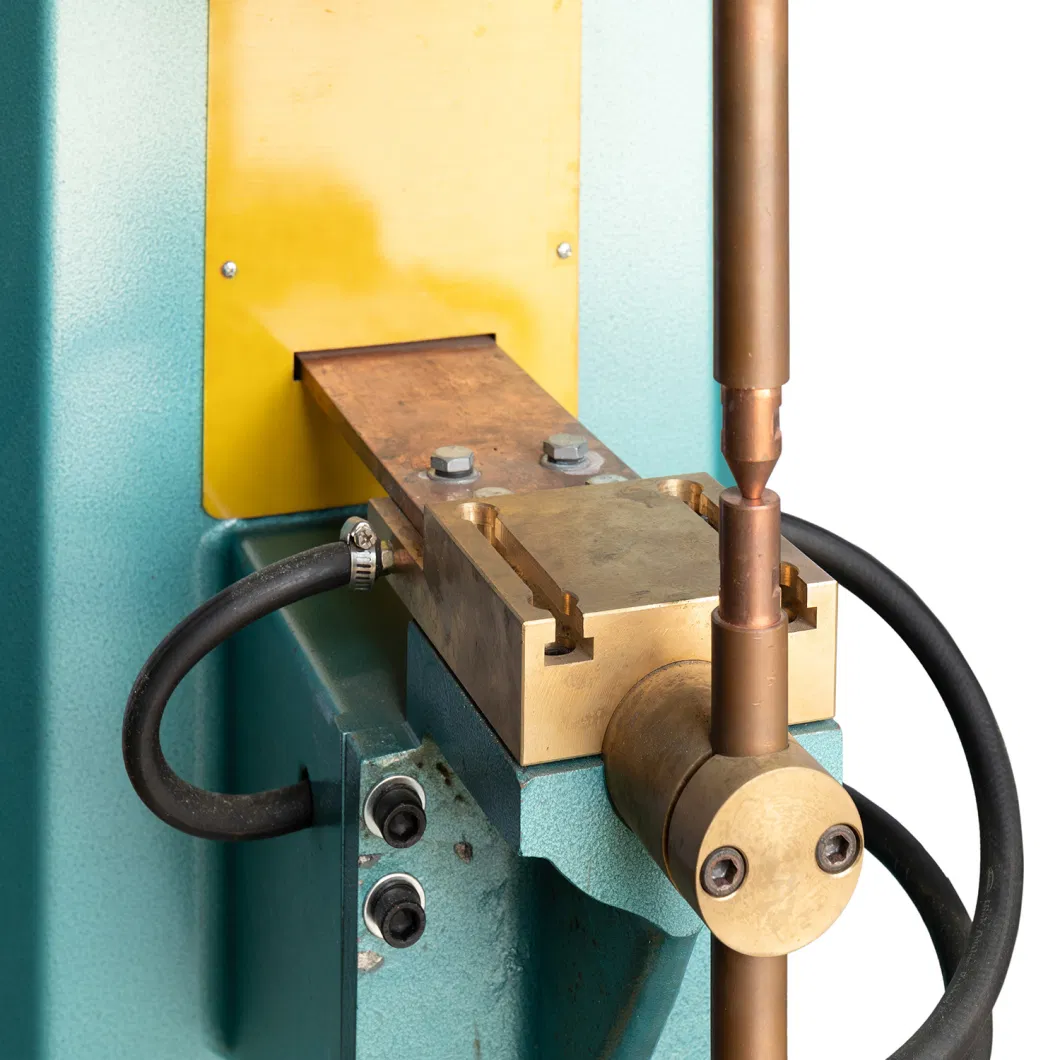

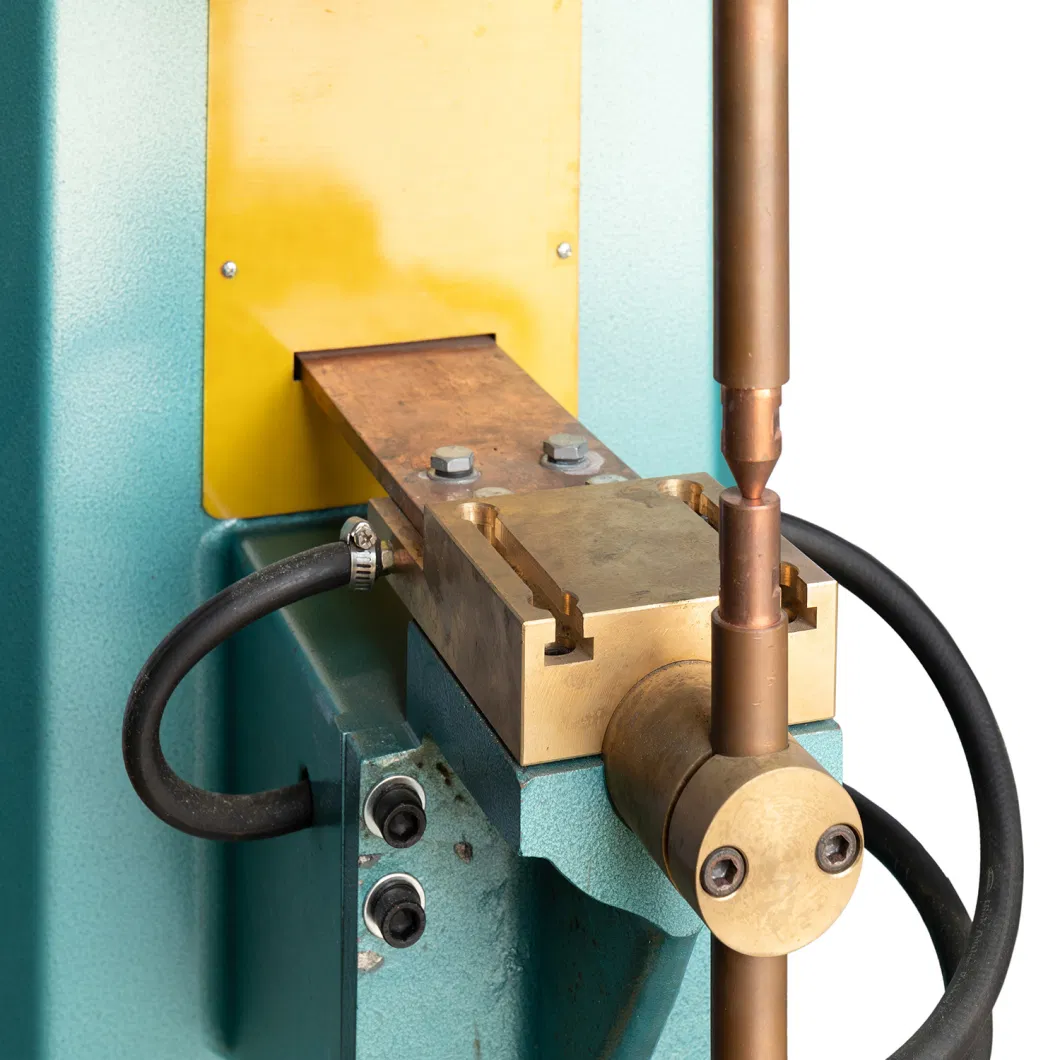

e)Interior structure is made of copper material

Product Display

Our Services

a)Help customer analyze product project and provide welding solution.

b)Freely sample welding test.

c)Provide professional welding solution.

e)Provide shipping/delivery information checking service.

f)After sales with online vedio technical support

d)One-year warranty of the whole machine

FAQ:

Q:Are you a factory or trading company?

A: We are a factory for more than 10 years and have our own trading company.

Q :Where is your factory located?

A :Our factory is located in No. 21 Guangping Road, Guangde Economic Development Zone, Xuancheng, Anhui of China.

Q:Why your welding machine is so expensive?

A:All the interior structure is made of copper material, which is more cost-effective.

Q: What are the advantages of Spot Welding Machine?

A: spot welding machine has higher accuracy, higher accuracy and more environmental, simple operation which is easy to realize mechanization and automation, improve the labor cost . With high productivity, no noise and harmful gases, in mass production, can be woven into the assembly line with other manufacturing processes.

a )Smaller pollution to power grid.

b)Continuous loop execute multiple welding specification

c) Preheating current, welding current and tempering current

d) used for welding special materials, such as welding aluminum, galvanized metal, etc.

e)automatically shut down the output and prompt the fault reason.

Why Choose Us?

a)12 Patents of welding machine

b)Thousand grade of warehouse, delivery time is guaranteed

c)Profession designer and engineer, assure production quality

d)CCC issued by China Quality Certification Center

e)Interior structure is made of copper material

| Product Information | |||||

| Type | DTN-25 | DTN-50 | DTN-63 | DTN-100 | DTN-200 |

| Rated Power (KVA) | 25 | 50 | 63 | 100 | 200 |

| Primary Voltage(V) | 380 | 380 | 380 | 380 | 380 |

| Duty Cycle(%) | 20 | 20 | 20 | 20 | 20 |

| Distance between arms(mm) | 220 | 220 | 240 | 300 | 300 |

| Stroke of top electrode(mm) | 25-50 | 25-50 | 25-80 | 25-80 | 25-80 |

| Pressure of compressed air (Pa) | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 |

| Maximum Electrode Force (N) | 5000 | 5000 | 8000 | 8000 | 8000 |

| Cooling Water Flow (L/min) | 3 | 3 | 4 | 4 | 4 |

| Max. welding thickness (A3 Copper plate) (mm) | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 |

| Dimension (L x W x H) (mm) | 880*450*1700 | 880*450*1700 | 980*460*1900 | 1050*460*2000 | 1050*460*2000 |

| Weight (kg) | 250 | 280 | 350 | 380 | 420 |

Product Display

Our Services

a)Help customer analyze product project and provide welding solution.

b)Freely sample welding test.

c)Provide professional welding solution.

e)Provide shipping/delivery information checking service.

f)After sales with online vedio technical support

d)One-year warranty of the whole machine

FAQ:

Q:Are you a factory or trading company?

A: We are a factory for more than 10 years and have our own trading company.

Q :Where is your factory located?

A :Our factory is located in No. 21 Guangping Road, Guangde Economic Development Zone, Xuancheng, Anhui of China.

Q:Why your welding machine is so expensive?

A:All the interior structure is made of copper material, which is more cost-effective.

Q: What are the advantages of Spot Welding Machine?

A: spot welding machine has higher accuracy, higher accuracy and more environmental, simple operation which is easy to realize mechanization and automation, improve the labor cost . With high productivity, no noise and harmful gases, in mass production, can be woven into the assembly line with other manufacturing processes.