- Overview

- Product Parameters

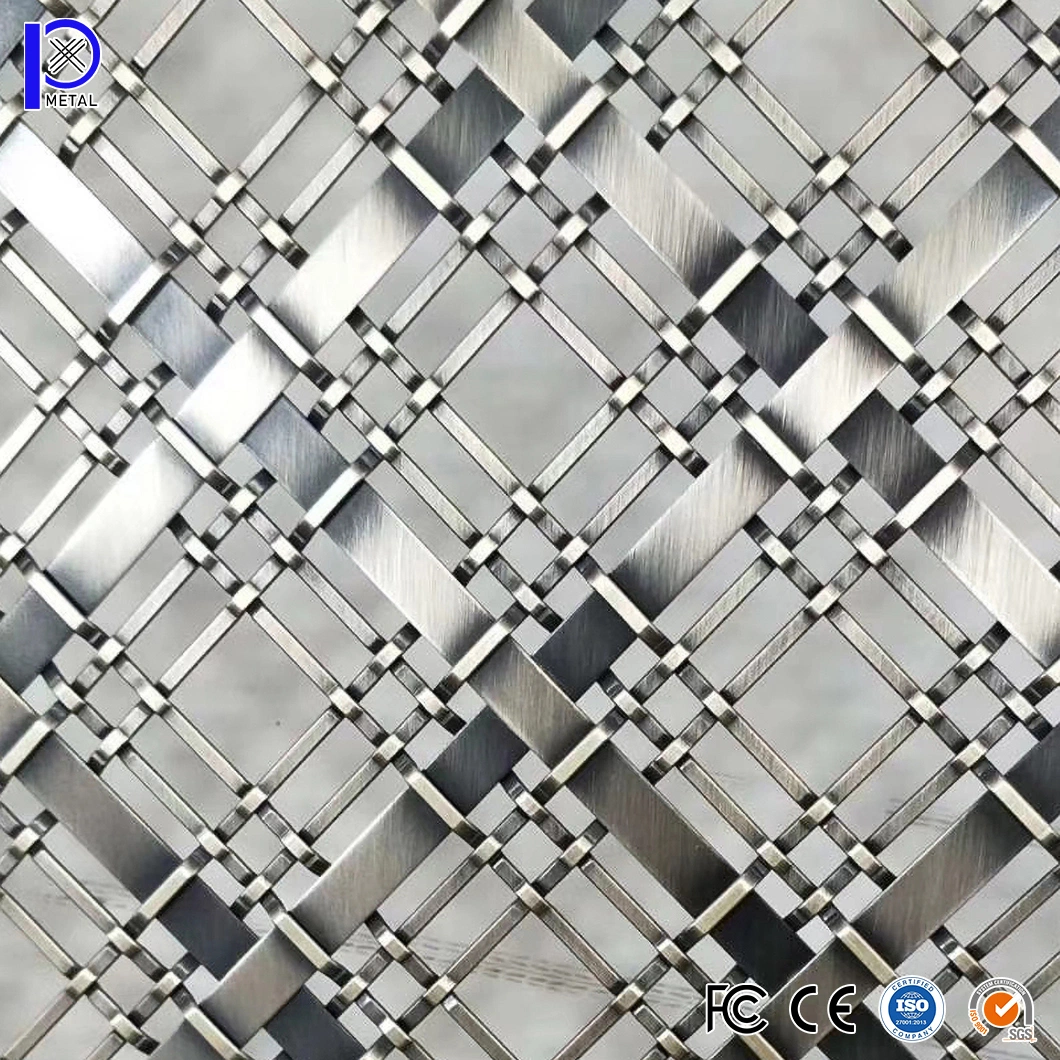

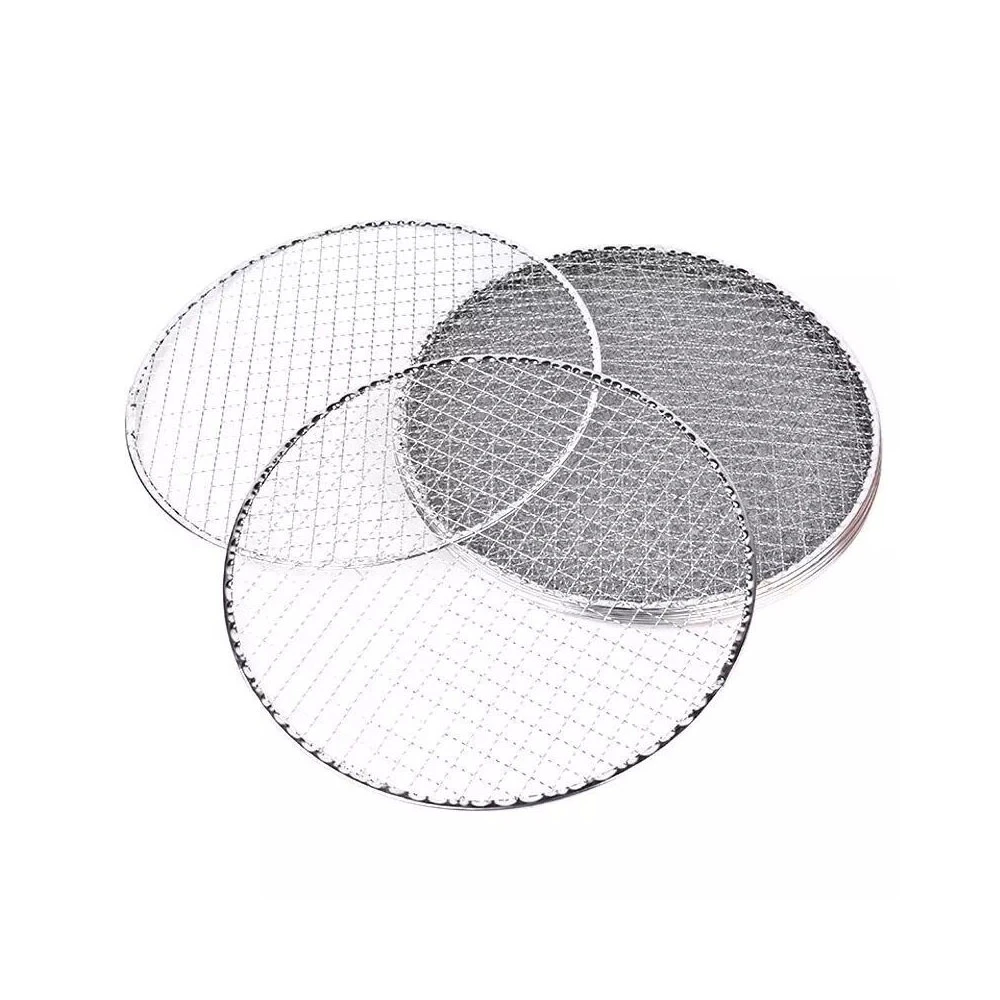

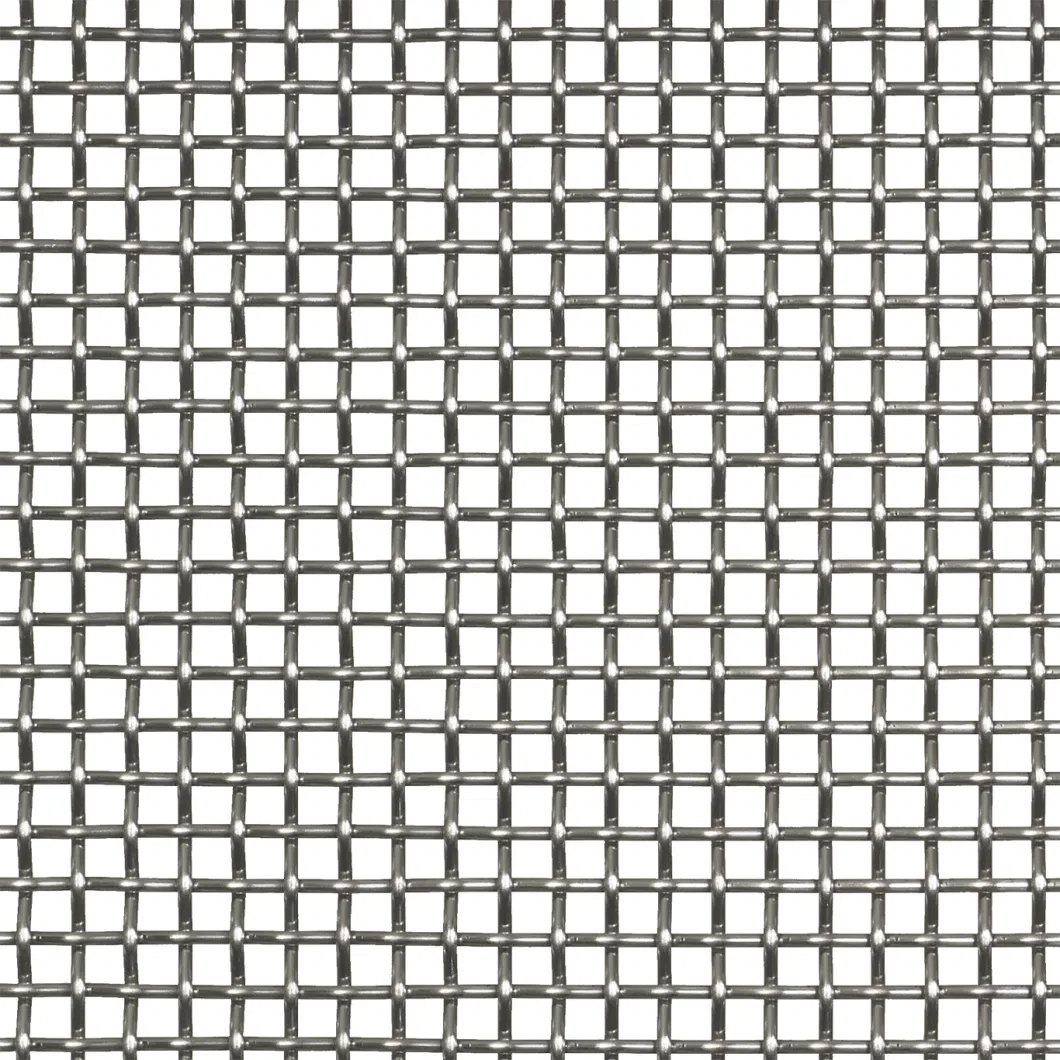

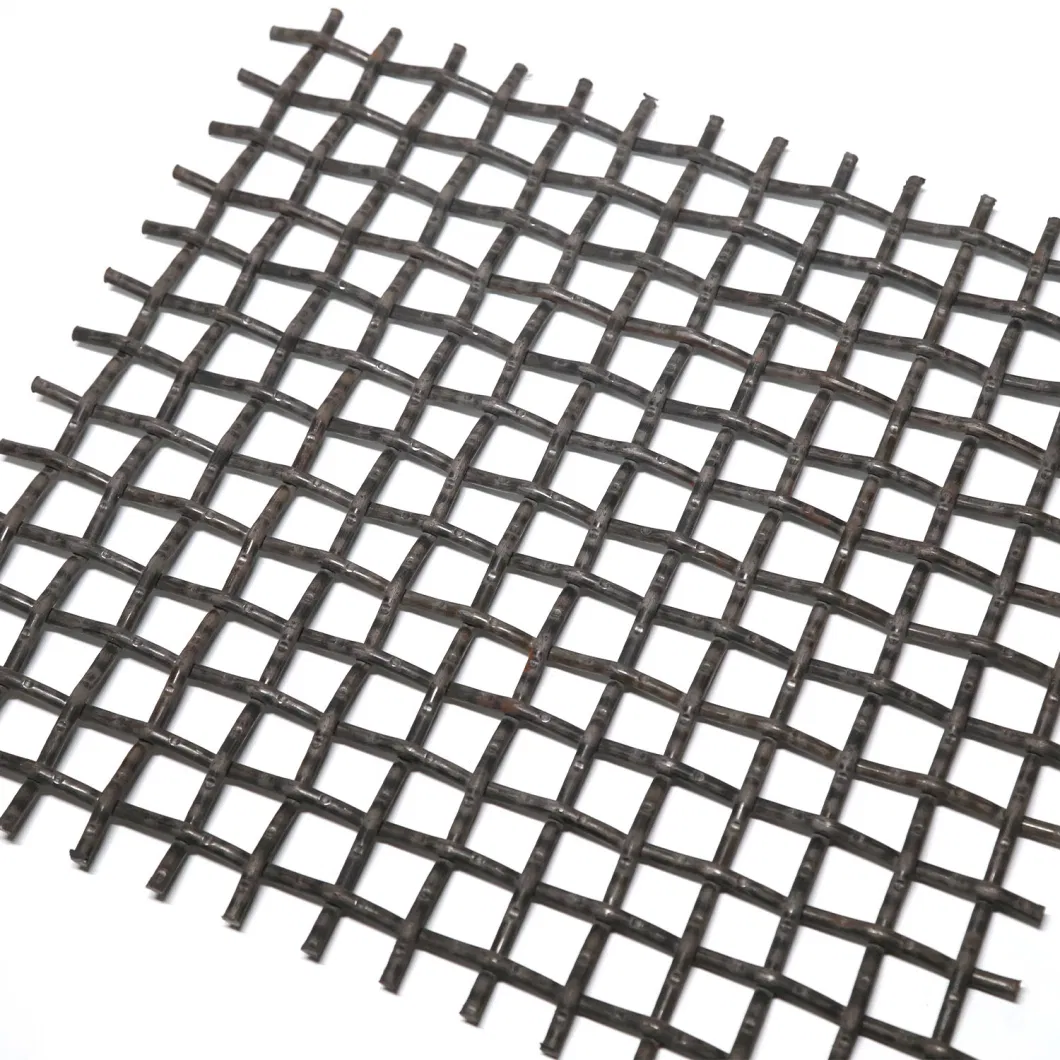

- Detailed Photos

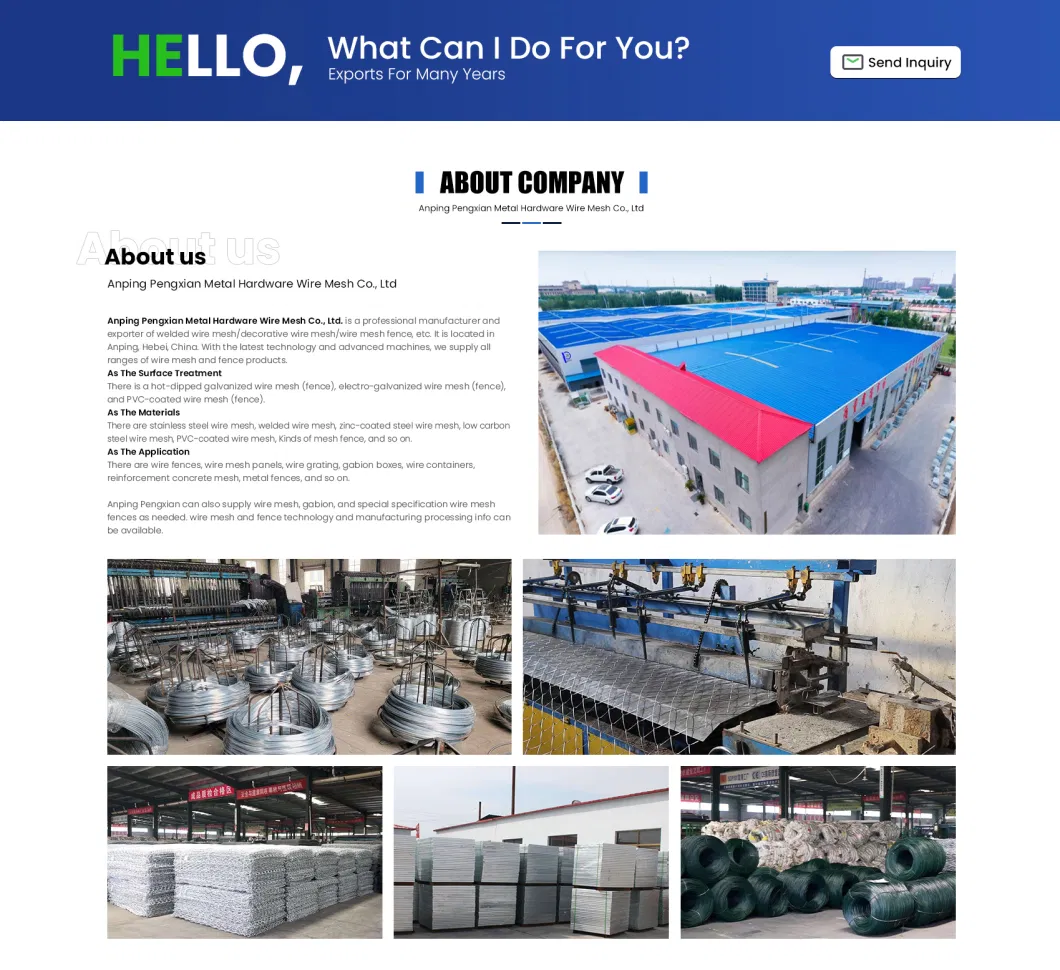

- Company Profile

- FAQ

Basic Info.

Model NO.

Crimped Wire Mesh

Weave Technique

Satin Weave

Weave Method

Two-Way Bending

Feature

Waterproof

Wire Diameter

0.50mm

Color

White

Packaging

Pallet

Certification

ASTM, ISO9001, RoHS, CE

Product Name

Woven Wire Mesh

Keywords

Crimped Wire Mesh

Other Name

Woven Crimped Wire Mesh

Wire Mesh Material

Stainless Steel Wire/Galvanized Wire/Mn Steel Wire

Wire Mesh Diameter

1.0mm

Cable Pitch

36mm

Width

0.5m - 2.5m

Type

Weave Wire Mesh

Wire Mesh Color

Requirement

Wire Mesh Hole Shape

Square Hole and Rectangle

Length

Customers Requirement

Wire Mesh Feature

Corrosion Resistance

Processing Service

Bending, Welding, Decoiling, Cutting, Punching

OEM or ODM

Accept

Sample

Accept

Transport Package

Standard Shipping Package or Customized

Specification

Standard Specification or Customized

Trademark

PENGXIAN WIRE MESH

Origin

Anping, China

HS Code

73143100

Production Capacity

500000 Square Meter Per Year

Product Description

Product Introduction

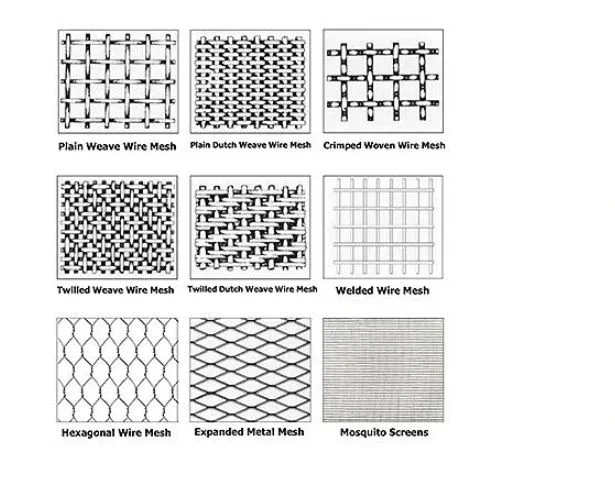

Crimped Wire Mesh Is Made Of Carbon Iron Wire, Galvanized Steel Wire, Or Stainless Steel Wire.

Weaving Patterns: Weaving After Crimping.

This Kind Of Wire Mesh Is Identified From A Wire Crimped Only In The Points Of Intersection, Before Weaving. Crimped Wire Mesh Is Only Made On Request And The Wire Used May Be Round Or Square.

Product Features:

Crimped Woven Wire Mesh Offers Great Dimensional Strength And Stability, Great Resistance To Abrasion, Uniform Openings, And Excellent Anti-Corrosion. It Is Usually Used As A Quarry Screen In Mines, Quarries, And Other Industrial Fields For Sieving, Grading, And Separating Screening Materials.

Basic Parameters:

Aperture Width: 10 - 120Mm In The Case Of Multi-Notch Meshes And 4 - 40Mm In The Case Of Single-Notch Meshes.

Wire Diameter: 1.0 - 5.5Mm.

Mesh Width: Up To 2000Mm.

Crimped Wire Mesh Is Supplied In The Form Of Sheets.

Weaving Types

Double Crimp Wire Mesh

Double Crimp Wire Mesh Is Manufactured With Pre-Crimped Wires To Obtain Precise Screening Apertures And Achieve Maximum Rigidity.

Generally, It Works Well In Conditions Where Materials Are Not Sticky Or Materials With A Small Tendency To peel or Wedge.

Flat Top Wire Mesh

Flat-Top Wire Mesh Is Manufactured With Wires Crimped On One Side Only To Create A Flat Surface, Thus Enhancing Its Durability And

Allowing Bigger Apertures With High Precision. It Is Generally Used For Coarse Mineral Screening.

Lock Crimp Wire Mesh

Double Crimp Wire Mesh Is Manufactured With Pre-Crimped Wires To Obtain Precise Screening Apertures And Achieve Maximum Rigidity.

Generally, It Works Well In Conditions Where Materials Are Not Sticky Or Materials With A Small Tendency To peel or Wedge.

| Wire Gauge | Wire Diameter | Mesh/Inch | Aperture | Weight |

| SWG | (mm) | (mm) | (kg/m2) | |

| 14 | 2 | 21 | 1 | 4.2 |

| 8 | 4.05 | 18 | 1 | 15 |

| 25 | 0.5 | 20 | 0.61 | 2.6 |

| 23 | 0.61 | 18 | 0.8 | 3.4 |

| 24 | 0.55 | 16 | 0.1 | 2.5 |

| 24 | 0.55 | 14 | 0.12 | 4 |

| 22 | 0.71 | 12 | 0.14 | 2.94 |

| 19 | 1 | 2.3 | 0.18 | 1.45 |

| 6 | 4.8 | 1.2 | 2 | 20 |

| 6 | 4.8 | 1 | 2 | 20 |

| 6 | 4.8 | 0.7 | 3 | 14 |

| 14 | 2 | 5.08 | 0.3 | 12 |

| 14 | 2 | 2.1 | 1 | 2.5 |

| 14 | 2 | 3.6 | 1.5 | 1.9 |