- Overview

- Product Description

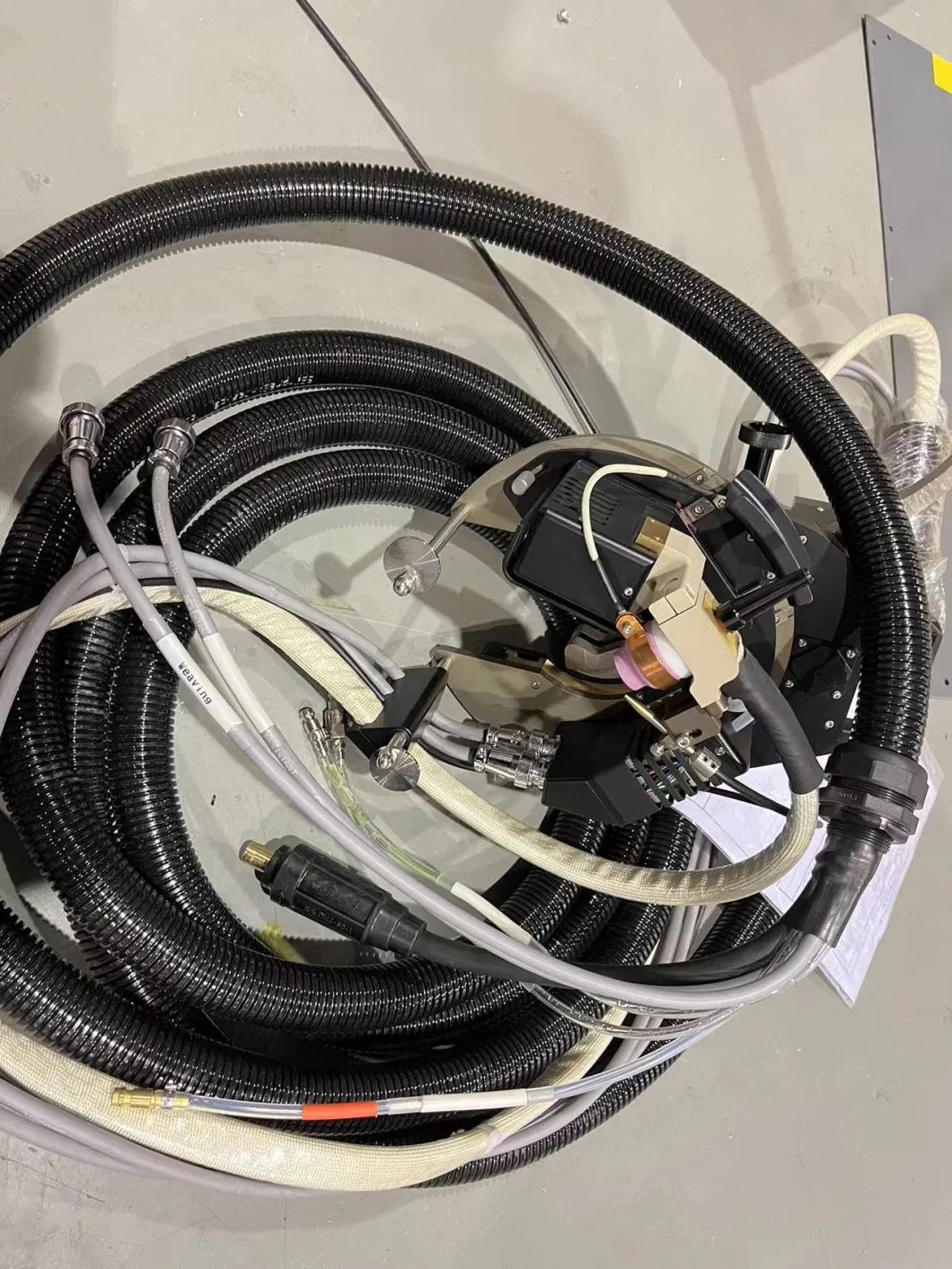

- Detailed Photos

- Product Parameters

- Packaging & Shipping

- Company Profile

Basic Info.

Product Description

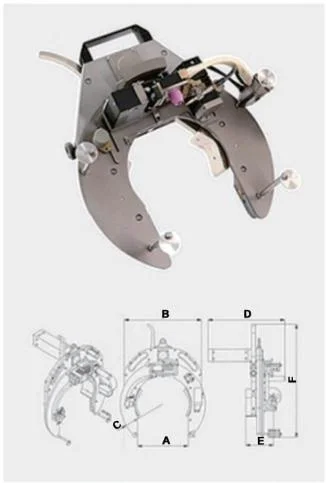

Open Orbital Weld Heads

2. With the speed measurement function with feedback, the rotation is more accurate and stable, and the angle of the welding seam is monitored in real-time. The rotation speed of the welding torch is accurate and stable, and the perfect welding quality is achieved;

3. With automatic arc length and yaw function, it can meet the welding of pipe fittings of different sizes;

4. The welding torch is cooled by circulating water, with a high-duty cycle, and it can work stably and reliably for a long time.

5. Under the same conditions, different pipe diameters can be welded without readjusting the welding parameters;

6. The welding torch adopts the Haval fixture, which can be adjusted according to the diameter of the pipe fittings so that the welding torch can firmly lock the pipe fittings.

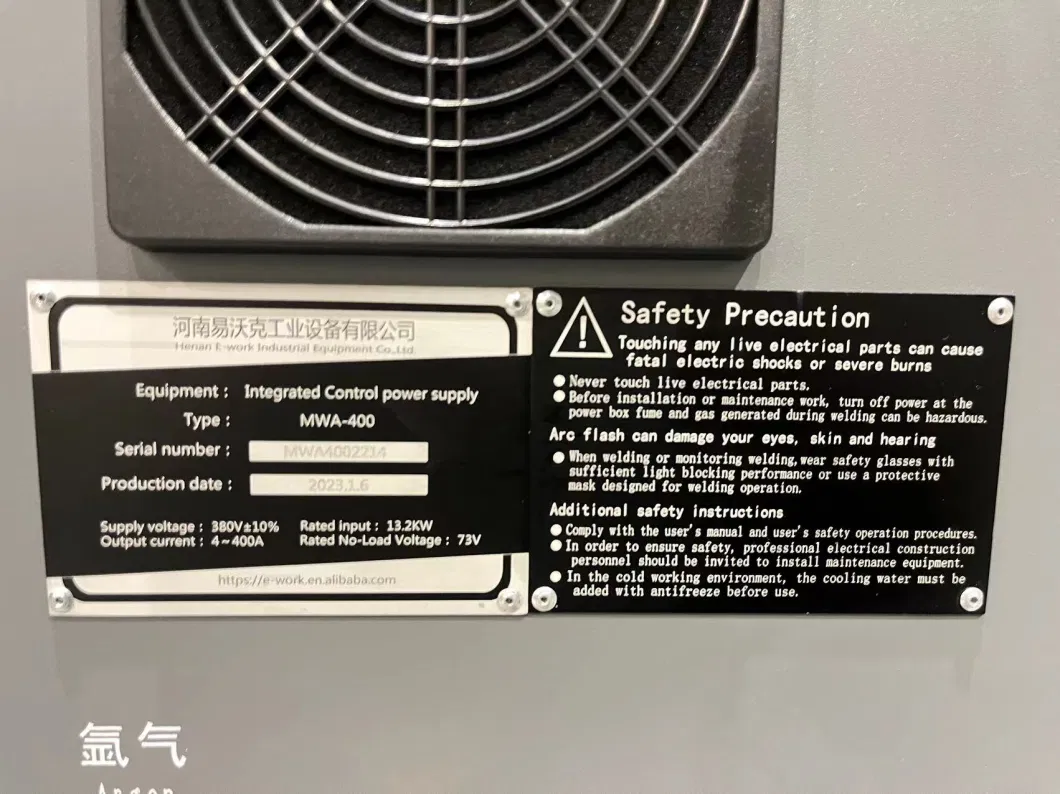

Power Control Unit

2. The equipment adopts a German Siemens PLC control system, EWM welding movement, Swiss Maxon motor, Omron relay, and other

imported configurations. Precise control of various input and output signals.

3. Using touch man-machine interface, fast switching between Chinese and English interfaces, color 10-inch touch screen, graphic

and step interface design, easy to operate and easy to learn and meet the requirements of different venues.

4. With functions such as parameter saving/printing, it can be operated with basic welding skills.

5. Real-time monitoring of welding parameters such as current, voltage, and speed during the welding process to ensure the safety

and efficiency of the welding process.

| Model | MWG-90 | MWG-170 | MWG-230 | MWG-325 |

| Welding range | 20mm-89mm | 63mm-168mm | 130mm-230mm | 159mm-325mm |

| Wall thickness | 1-10mm | 2-10mm | 2-10mm | 2-10mm |

| Protective gas | Argon | Argon | Argon | Argon |

| Cooling method | Water-cooling | Water-cooling | Water-cooling | Water-cooling |

| Tungsten diameter | 2.4mm | 2.4mm | 2.4mm | 2.4mm |

The open orbital welding head and wire feeder are packed in an alloy box and then pack with the power control unit together in the wooden box.

Henan E-work Industrial Equipment Co., Ltd. is a professional company dedicated to the R&D, production, and sales of piping working machines and tools. In line with the business tenet of "piping solutions expert" and the mission of "making work easy and efficient", we have independently developed and produced a series of products that customers love. Our product series mainly include pipe-cutting machines, pipe-welding machines, pipe-beveling machines, pipe-bending machines, pipe threading machines, HDPE pipe machines, and related tools. These products are widely used for stainless pipe, steel pipe, galvanized pipe, mild steel, and plastic pipes.

Our company not only has a professional and skilled workforce but also has established a complete and complete quality management system. We are committed to providing customers with world-class products and look forward to sincere and friendly cooperation with our customers to have a good business together.