- Overview

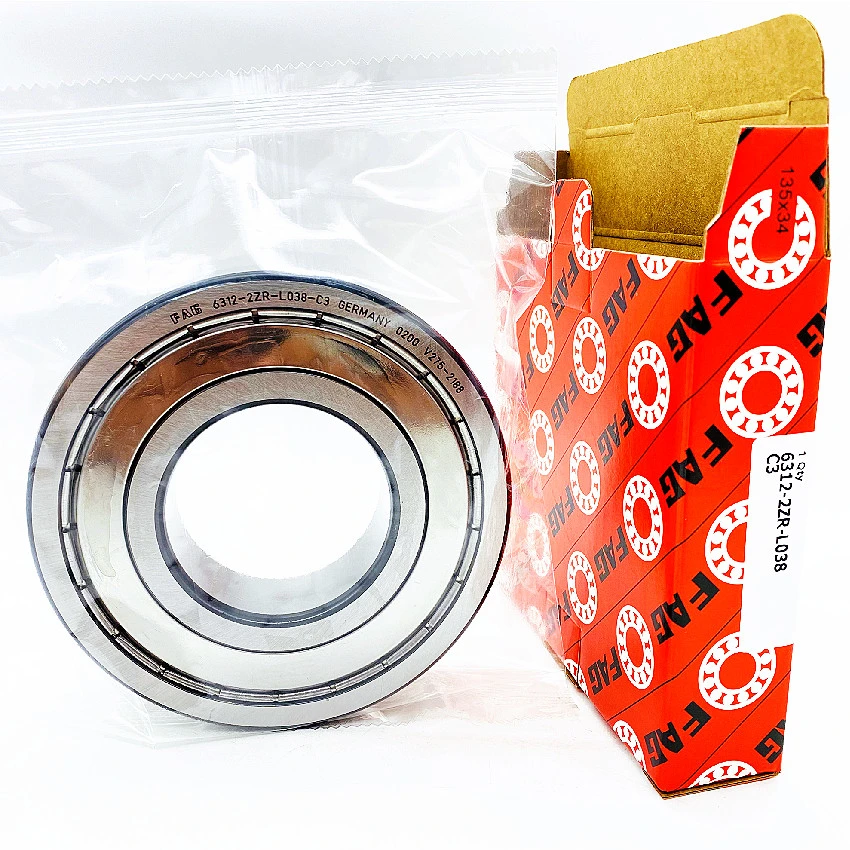

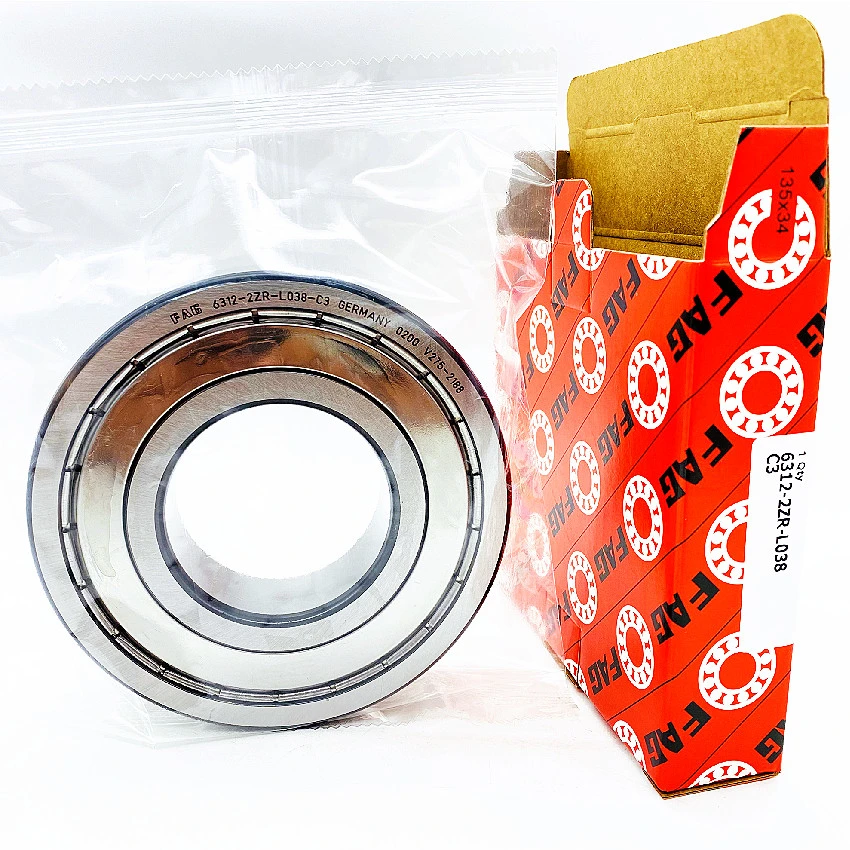

- Detailed Photos

- Products Details

- Packaging & Shipping

Basic Info.

Model NO.

691

Rows Number

Single

Load Direction

Radial Bearing

Material

Bearing Steel

Quanlity

P0, P6, P5, P4, P2, Z1V1, Z2V2, Z3V3

Hardness

HRC60-63

Sealling Way

Dual Seals & Triple Lips Seals & F Seals

Available

2RS1, 2z, DDU, Zz, VV, Open, Nr, M, C0, C2, C3, C4

Application

Motor, Motorcycle, Automobile

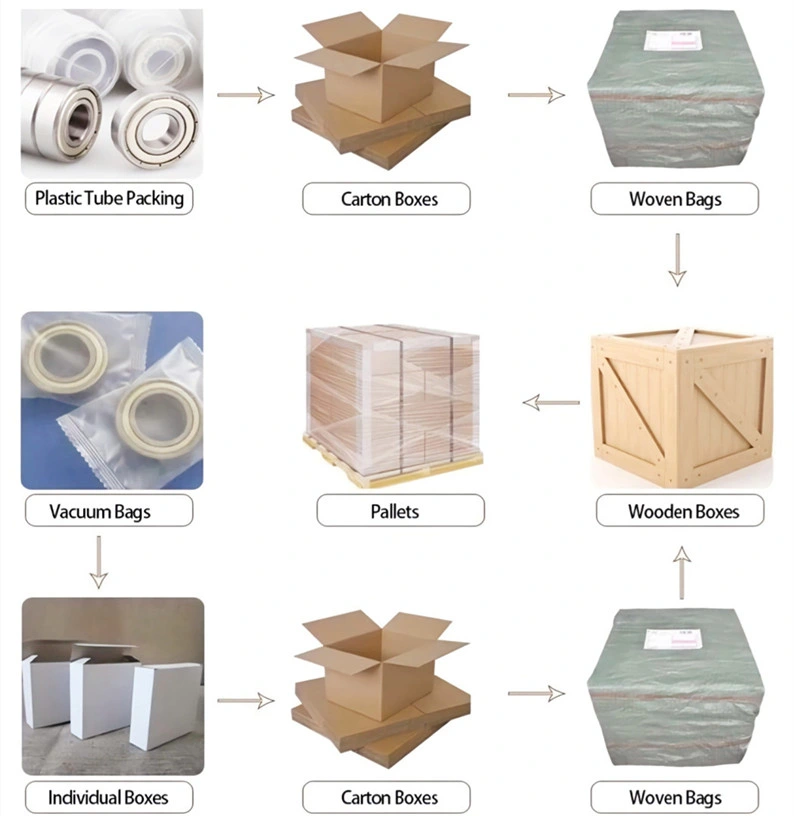

Transport Package

Plastic Bag+Single Box+Carton+Pallet

Specification

Ball bearings

Trademark

NSK, NTN, TIMKEN, NACHI

Origin

China

HS Code

8483200000

Production Capacity

50000 PCS/Month

Product Description

Mini Bearing 691 692 R133 ZZ 2Z R133ZZ 691ZZ 692ZZ 1000091 1000092 Deep Groove Ball Miniature Bearings

<<Wide Application>> Rolling bearings are used in a range of applications from agricultural machinery to conveying equipment, robotics, dental equipment, elevators, ship rudder shafts, skateboards, inline skates, and scooters, among others.

<<Material>> The bearing is made of high-quality bearing steel, good durability, and resistance to heavy loads.

<<Features>> Pre-lubricated, normal accuracy, less friction, higher speed, smooth and low noise

<<Strictly Shielded>> Shields on both sides of the bearing help to keep dust out.

Company Advantages

1. FREE SAMPLES: contact us by email or trade manager, and we will send the free samples according to your request.

2. World-Class Bearing: We provide our customers with all types of bearings of world-class quality.

3. OEM or Non-Stand Bearings: Any requirement for Non-standard bearings is Easily Fulfilled by us due to our vast knowledge and links in the industry.

4. Genuine products With Excellent Quality: Company has always proved the 100% quality products it provides with genuine intent.

5. After-Sales Service and Technical Assistance: Company provides after-sales service and technical assistance as per the customer's requirements and needs.

6. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

7. Cost Saving: We provide long-life, shock-resistant, and high-reliability bearings with excellent quality and better performance. Resulting in increased cost savings.

8. Attending customer queries promptly: We believe that if customers are satisfied then it proves our worth well. Customers are always given quick support.

<<Wide Application>> Rolling bearings are used in a range of applications from agricultural machinery to conveying equipment, robotics, dental equipment, elevators, ship rudder shafts, skateboards, inline skates, and scooters, among others.

<<Material>> The bearing is made of high-quality bearing steel, good durability, and resistance to heavy loads.

<<Features>> Pre-lubricated, normal accuracy, less friction, higher speed, smooth and low noise

<<Strictly Shielded>> Shields on both sides of the bearing help to keep dust out.

>> Single-row and double row

>> Open and sealed types

>> Chrome steel, ceramic or hybrid materials

>> Polyamide, steel, and brass cage assemblies

- 6000 series: 604.605.606.607.608.609.6000.6001.6002.6003.6004.6005.6006.6007.6008........

- 6200 series: 624.625.626.627.628.629.6200.6201.6202.6203.6204.6205.6206.6207.6208........

- 6300 series: 634.635.636.637.638.639.6300.6301.6302.6303.6304.6305.6306.6307.6308........

- 6400 series: 6403.6404.6405.6406.6407.6408.6409.6410.6411.6412.6413.6414.6415........

- 6700 series: 673.674.675.676.677.678.679.6700.6701.6702.6703.6704.6705

- 6800 series: 685.686.687.688.689.6800.6801.6802.6803.6804.6805.6806.6807.6808........

- 6900 series: 695.696.697.698.699.6900.6901.6902.6903.6904.6905.6906.6907.6908.6909........

- 16000 series: 16001.16002.16003.16004.16005.16006.16007.16008.16009.16010.16011........

>> Open and sealed types

>> Chrome steel, ceramic or hybrid materials

>> Polyamide, steel, and brass cage assemblies

- 6000 series: 604.605.606.607.608.609.6000.6001.6002.6003.6004.6005.6006.6007.6008........

- 6200 series: 624.625.626.627.628.629.6200.6201.6202.6203.6204.6205.6206.6207.6208........

- 6300 series: 634.635.636.637.638.639.6300.6301.6302.6303.6304.6305.6306.6307.6308........

- 6400 series: 6403.6404.6405.6406.6407.6408.6409.6410.6411.6412.6413.6414.6415........

- 6700 series: 673.674.675.676.677.678.679.6700.6701.6702.6703.6704.6705

- 6800 series: 685.686.687.688.689.6800.6801.6802.6803.6804.6805.6806.6807.6808........

- 6900 series: 695.696.697.698.699.6900.6901.6902.6903.6904.6905.6906.6907.6908.6909........

- 16000 series: 16001.16002.16003.16004.16005.16006.16007.16008.16009.16010.16011........

| Miniature Bearings | Thin Section Bearings | Flanged Ball Bearings |

| Angular Contact Ball Bearings | Deep Groove Ball Bearings | Thrust Ball Bearings |

| Self Aligning Ball Bearings | Stainless Steel Ball Bearings | Ceramic Ball Bearings |

Chrome steel miniature bearings for shaft sizes from 1.5mm to 9mm

| 609-2RZ-C3 | 9 mm | 618/4-ZZ | 4 mm | 618/5-ZZ | 5 mm |

| 629-2RS-C3 | 9 mm | 618/4-2RS | 4 mm | 618/5-2RS | 5 mm |

| 618/3 | 3 mm | 618/4-2RZ | 4 mm | 618/5-2RZ | 5 mm |

| 618/3-ZZ | 3 mm | 619/4 | 4 mm | 619/5 | 5 mm |

| 618/3-2RS | 3 mm | 619/4-ZZ | 4 mm | 619/5-ZZ | 5 mm |

| 618/3-2RZ | 3 mm | 619/4-2RS | 4 mm | 619/5-2RS | 5 mm |

| 619/3 | 3 mm | 619/4-2RZ | 4 mm | 619/5-2RZ | 5 mm |

| 619/3-ZZ | 3 mm | 604 | 4 mm | 605 | 5 mm |

| 619/3-2RS | 3 mm | 604-ZZ | 4 mm | 605-ZZ | 5 mm |

| 603 | 3 mm | 604-2RS | 4 mm | 605-2RS | 5 mm |

| 603-ZZ | 3 mm | 604-2RZ | 4 mm | 605-2RZ | 5 mm |

| 623 | 3 mm | 624 | 4 mm | 625 | 5 mm |

| 623-ZZ | 3 mm | 624-ZZ | 4 mm | 625-ZZ | 5 mm |

| 623-2RS | 3 mm | 624-2RS | 4 mm | 625-2RS | 5 mm |

| 623-2RZ | 3 mm | 624-2RZ | 4 mm | 625-2RZ | 5 mm |

| 633 | 3 mm | 634 | 4 mm | 635 | 5 mm |

| 633-ZZ | 3 mm | 634-ZZ | 4 mm | 635-ZZ | 5 mm |

| 633-2RS | 3 mm | 634-2RS | 4 mm | 635-2RS | 5 mm |

| 633-2RZ | 3 mm | 634-2RZ | 4 mm | 635-2RZ | 5 mm |

| 618/4 | 4 mm | 618/5 | 5 mm | 618/6 | 6 mm |

Some advantages of HOJE Thin Section Ball Bearings are:

• Light weight • Space Saving • High stiffness

• Accurate positioning • Reduced overall design costs

• Can be successfully used in numerous bearing applications

• Easily modified or customized • Multi-load capabilities

• Variety of cross-sections & sizes

• ABEC 1,3,5, and 7 available • Race materials: 440C, 17-4PH, M50

• Ball materials: 440C, ceramic

• Separator options: Phenolic, nylon, toroid, formed wire, spacer balls, full complement, helical coil springs

Thin Section Bearing Applications:

• Polishing equipment • Textile equipment

• Paper-making and converting equipment

• Printing machinery

• Specialized industrial equipment

• Tube and pipe-cutting equipment

• Light weight • Space Saving • High stiffness

• Accurate positioning • Reduced overall design costs

• Can be successfully used in numerous bearing applications

• Easily modified or customized • Multi-load capabilities

• Variety of cross-sections & sizes

• ABEC 1,3,5, and 7 available • Race materials: 440C, 17-4PH, M50

• Ball materials: 440C, ceramic

• Separator options: Phenolic, nylon, toroid, formed wire, spacer balls, full complement, helical coil springs

Thin Section Bearing Applications:

• Polishing equipment • Textile equipment

• Paper-making and converting equipment

• Printing machinery

• Specialized industrial equipment

• Tube and pipe-cutting equipment

Flanged bearings have a solid steel flange on the outer ring. This allows the bearing to be more easily located in a housing. The flange can also help to prevent axial movement of the bearing in the event of a thrust load on the bearing.

| Bearing Number | Bore | Outer | Width | Flange Outer | Flange Thickness |

| F6800 | 10 mm | 19 mm | 5 mm | 21 mm | 1 mm |

| F6900 | 10 mm | 22 mm | 6 mm | 25 mm | 1.5 mm |

| F6801 | 12 mm | 21 mm | 5 mm | 23 mm | 1.1 mm |

| F6901 | 12 mm | 24 mm | 6 mm | 26 mm | 1.5 mm |

| F6802 | 15 mm | 24 mm | 5 mm | 26 mm | 1.1 mm |

| F6902 | 15 mm | 28 mm | 7 mm | 30 mm | 1.5 mm |

| F6803 | 17 mm | 26 mm | 5 mm | 28 mm | 1.1 mm |

| F6903 | 17 mm | 30 mm | 7 mm | 32 mm | 1.5 mm |

| F6804 | 20 mm | 32 mm | 7 mm | 35 mm | 1.5 mm |

| F6904 | 20 mm | 37 mm | 9 mm | 40 mm | 2 mm |

| F6805 | 25 mm | 37 mm | 7 mm | 40 mm | 1.5 mm |

| F6905 | 25 mm | 42 mm | 9 mm | 45 mm | 2 mm |

| F6806 | 30 mm | 42 mm | 7 mm | 45 mm | 1.5 mm |

| F6906 | 30 mm | 47 mm | 9 mm | 50 mm | 2 mm |

| F6807 | 35 mm | 47 mm | 7 mm | 50 mm | 1.5 mm |

| F6907 | 35 mm | 55 mm | 10 mm | 58 mm | 2.5 mm |

| F6808 | 40 mm | 52 mm | 7 mm | 55 mm | 1.5 mm |

| F6908 | 40 mm | 62 mm | 12 mm | 65 mm | 2.5 mm |

| F6809 | 45 mm | 58 mm | 7 mm | 61 mm | 1.5 mm |

| F6909 | 45 mm | 68 mm | 12 mm | 71 mm | 2.5 mm |

| F6810 | 50 mm | 65 mm | 7 mm | 68 mm | 1.5 mm |

| F6910 | 50 mm | 72 mm | 12 mm | 75 mm | 2.5 mm |

| Our Stainless Steel and Thermoplastic Units outperform under the toughest of conditions. • Easy to install • Reduces production downtime • Complies with food safety regulations • Long bearing life • Can be customized to meet specific customer requirements • HOJE offers product stocking programs | Stainless Steel and Thermoplastic housing: • Cleaning and chemical resistant • 440C Stainless Steel Bearings • High Tensile Strength Housings • Withstands Regular Washdowns • Solid Stainless Steel Bolt Hole Bush |

Properties advantages of ceramic bearings compared with steel ball bearings:

1. Higher limiting speeds: Ceramics is lighter than steel and can effectively restrain the centrifugal force, therefore enhancing the limiting speeds.

2. Higher precision usage: Ceramic has a higher hardness and elastic modulus than steel, which means ceramic bearings are more rigid than steel bearings, so therefore can be used in higher precision conditions.

3. Longer life: Lighter ceramic leads to a lower centrifugal force, this will extend the life of the bearing. Furthermore, the friction coefficient of ceramic is lower than steel, which also extends the life of the bearing

4. Higher temperature usage: Ceramic is more mechanically stable at elevated temperatures, therefore they could be used under higher temperatures.

5. Temperature-variation usage: Ceramics has a lower thermal expansion coefficient, and the clearance and tolerance variation is lower than those of steel bearings, which leads to a greater variation in the temperature range.

6. Better seizure resistance: Ceramics has a smaller thermal expansion coefficient; indicating less thermal deformation, therefore enhancing seizure resistance.

7. Could run without oil or grease: Ceramic never rusts and is self-lubricated, therefore can be used in applications that require no oil or grease.

8. Resistant to acid, alkali, and salt: The chemical industry is the largest potential application industry of ceramic bearings to be exploited.

9. More suitable for magnetic applications: Our ceramic bearings are non-magnetic, which means it is difficult for magnetic particles to adhere to the race, therefore reducing particle abrasion.

1. Higher limiting speeds: Ceramics is lighter than steel and can effectively restrain the centrifugal force, therefore enhancing the limiting speeds.

2. Higher precision usage: Ceramic has a higher hardness and elastic modulus than steel, which means ceramic bearings are more rigid than steel bearings, so therefore can be used in higher precision conditions.

3. Longer life: Lighter ceramic leads to a lower centrifugal force, this will extend the life of the bearing. Furthermore, the friction coefficient of ceramic is lower than steel, which also extends the life of the bearing

4. Higher temperature usage: Ceramic is more mechanically stable at elevated temperatures, therefore they could be used under higher temperatures.

5. Temperature-variation usage: Ceramics has a lower thermal expansion coefficient, and the clearance and tolerance variation is lower than those of steel bearings, which leads to a greater variation in the temperature range.

6. Better seizure resistance: Ceramics has a smaller thermal expansion coefficient; indicating less thermal deformation, therefore enhancing seizure resistance.

7. Could run without oil or grease: Ceramic never rusts and is self-lubricated, therefore can be used in applications that require no oil or grease.

8. Resistant to acid, alkali, and salt: The chemical industry is the largest potential application industry of ceramic bearings to be exploited.

9. More suitable for magnetic applications: Our ceramic bearings are non-magnetic, which means it is difficult for magnetic particles to adhere to the race, therefore reducing particle abrasion.

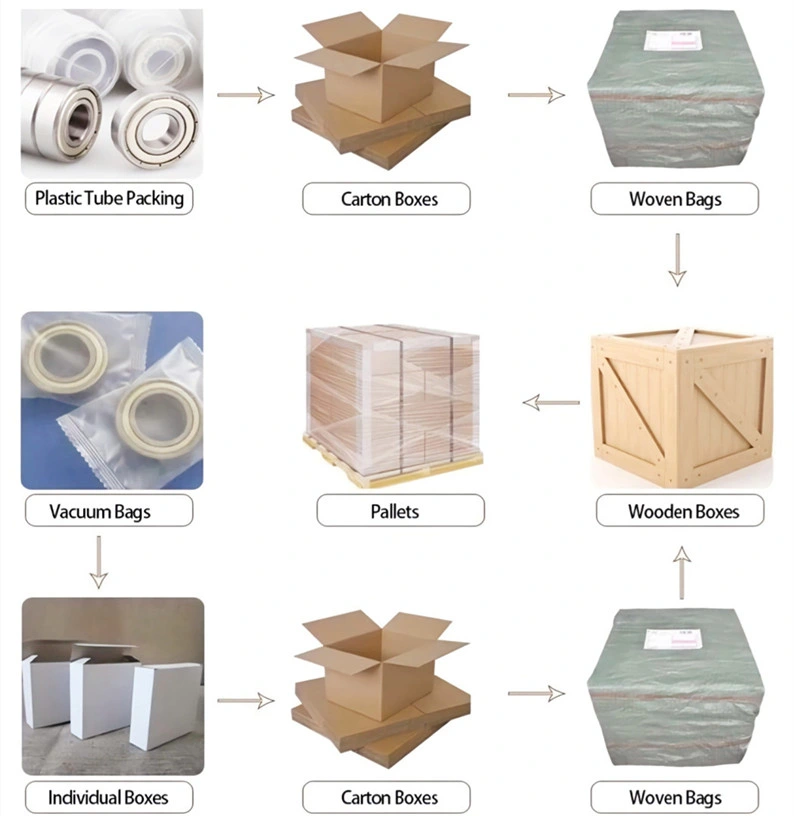

| Packaging | |

| 1)Commercial Bearings packaging: 1pc/plastic bag + color box + carton + pallet | |

| 2)Industrial Bearings packaging | |

| 3)According to the requirement of customers | |

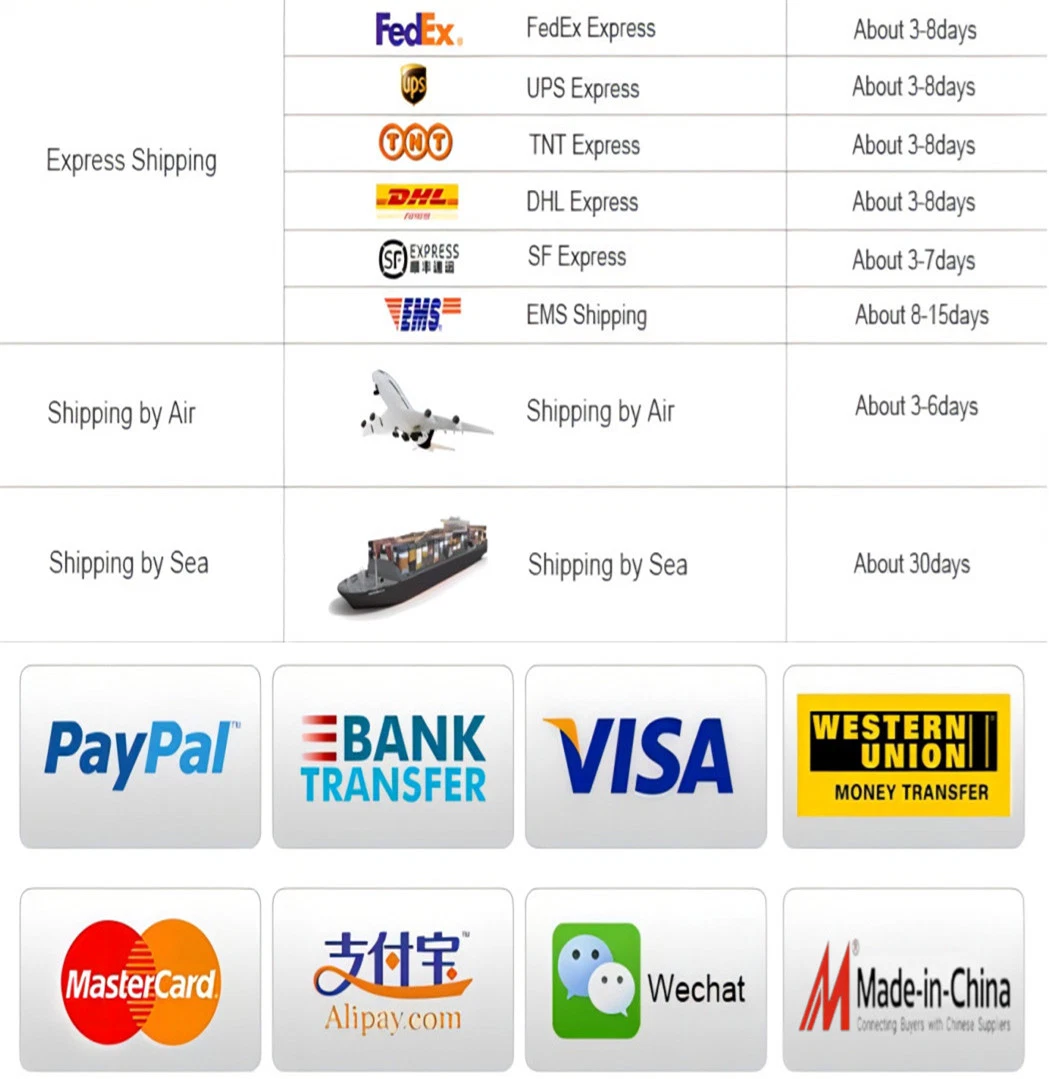

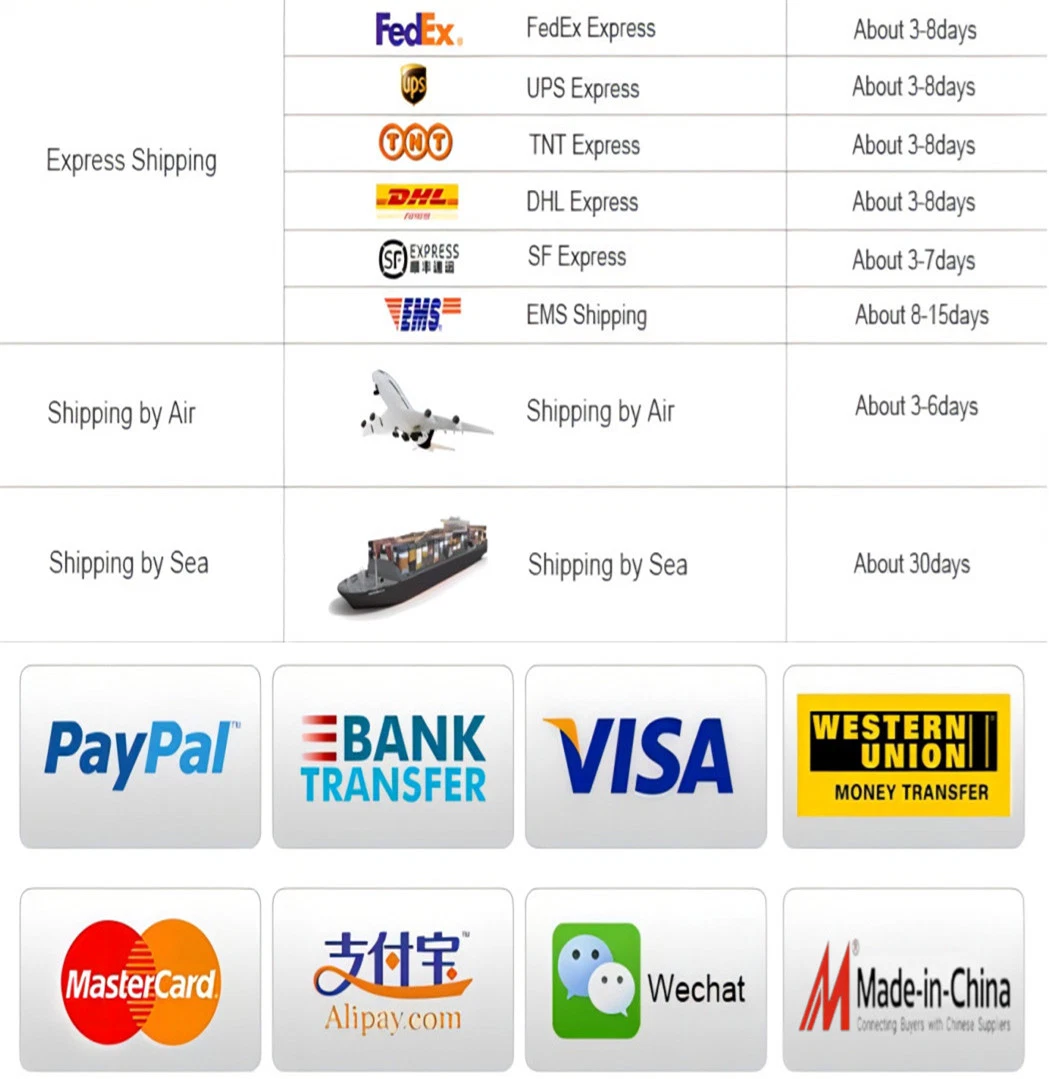

| Payment | |

| 1) T/T:30% deposit, 70% should be paid before shipment. | |

| 2) L/C at sight. (high bank charge, not suggested, but acceptable ) | |

| 3) 100% Western Union in advance. (especially for air shipment or small amounts) | |

| Delivery | |

| 1) Less than 45 KGS, we will send by express. ( Door to Door, Convenient ) | |

| 2) Between 45 - 200 KGS, we will send by air transport. ( Fastest and safest, but expensive ) | |

| 3) More than 200 KGS, we will send by sea. ( Cheapest, but long time ) | |

Company Advantages

1. FREE SAMPLES: contact us by email or trade manager, and we will send the free samples according to your request.

2. World-Class Bearing: We provide our customers with all types of bearings of world-class quality.

3. OEM or Non-Stand Bearings: Any requirement for Non-standard bearings is Easily Fulfilled by us due to our vast knowledge and links in the industry.

4. Genuine products With Excellent Quality: Company has always proved the 100% quality products it provides with genuine intent.

5. After-Sales Service and Technical Assistance: Company provides after-sales service and technical assistance as per the customer's requirements and needs.

6. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

7. Cost Saving: We provide long-life, shock-resistant, and high-reliability bearings with excellent quality and better performance. Resulting in increased cost savings.

8. Attending customer queries promptly: We believe that if customers are satisfied then it proves our worth well. Customers are always given quick support.