Basic Info.

Model NO.

low temperature wire

Slag Characteristic

Acidic

Extended Length

10-20mm

Product Name

Aluminum Welding Wire

Diameter

0.8-4.0mm

OEM

Accept OEM

Certificate

CE ISO Lr BV TUV

Weight

5kg/Box,7kg/Spool

Package

Plastic Spool

Feature

Excellent Welding Performance

Transport Package

7kg/Spool

Specification

0.8-4.0mm

Trademark

xunzhuo

Origin

China

Production Capacity

5000tons/Month

Product Description

Product Description:

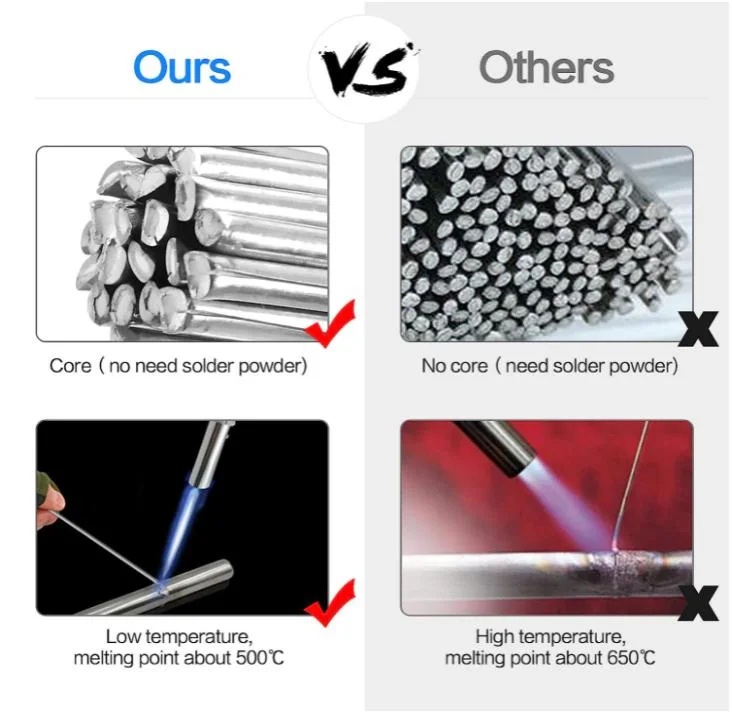

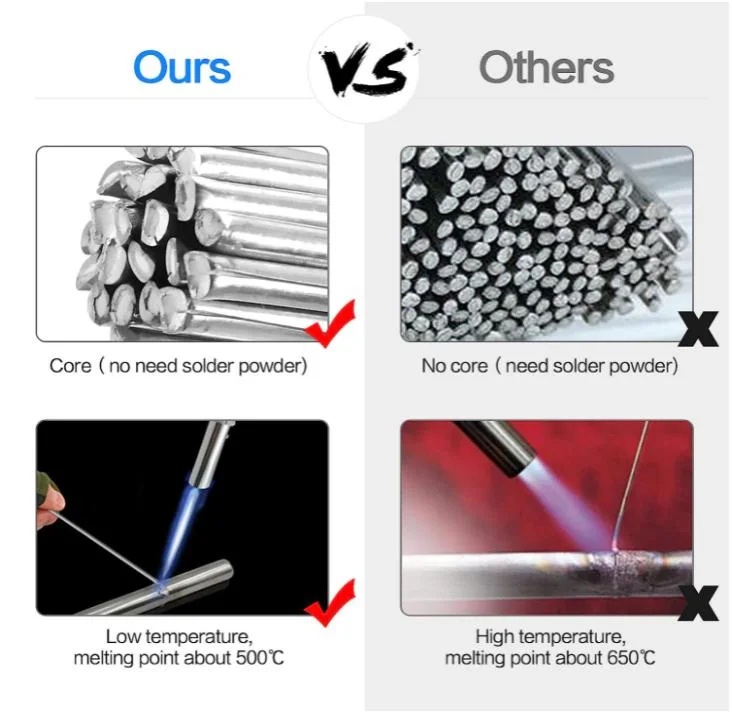

Metal Universal Welding Wire easy to use Aluminum Flux Core Welding Wire, Solution Welding Flux-cored Rods No Flux Required, Super Low Melting Point wire

Chemical composition:

This product is with excellent plasticity, impact toughness and crack resistance. Its main characteristics are as follow.

1. Argon has good protective results and high quality welding can be obtained.

2. The arc has stable burning and shallow penetration, which is quite suitable for thin plates.

3. Easy to operate, all-position welding. One-side welding with back tormation.

4. Beautiful appearance of welding and no spatters.

AWS ER5356/ER4043

Production process

1. very low welding cost, high productivity and low electricity consumption.

2. excellent welding performance, stable arc, low spatter, easy slag removal.

3. perfect welding seam forming, small weld metal stomatal sensitivity.

4. easy operating, all position welding.

5. very low hydrogen content in the weld and lower nitrogen content, excellent crack-resistance.

6. little deformation after welding.

7. wide applicability. suitable for welding thin, medium and thick plates.

8. Suitably wide range of welding current.

Application

Applicable for single pass and multi-pass welding of carbon steel and low alloy steel and is widely used in such fields as automobile industry, construction machinery manufacturing, ship building, metallurgical and mining equipment manufacturing, building, petrochemical industry etc. Also applicable for high-speed welding of sheets and pipeline steel.

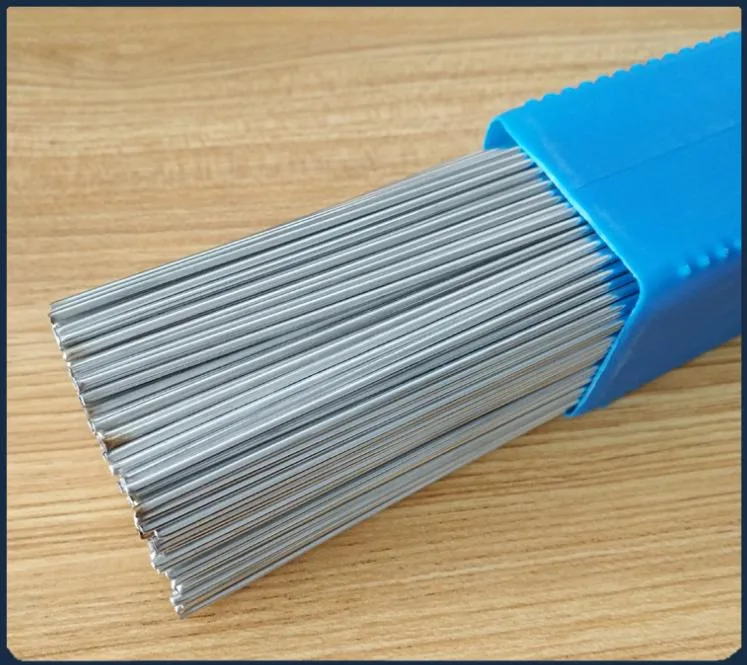

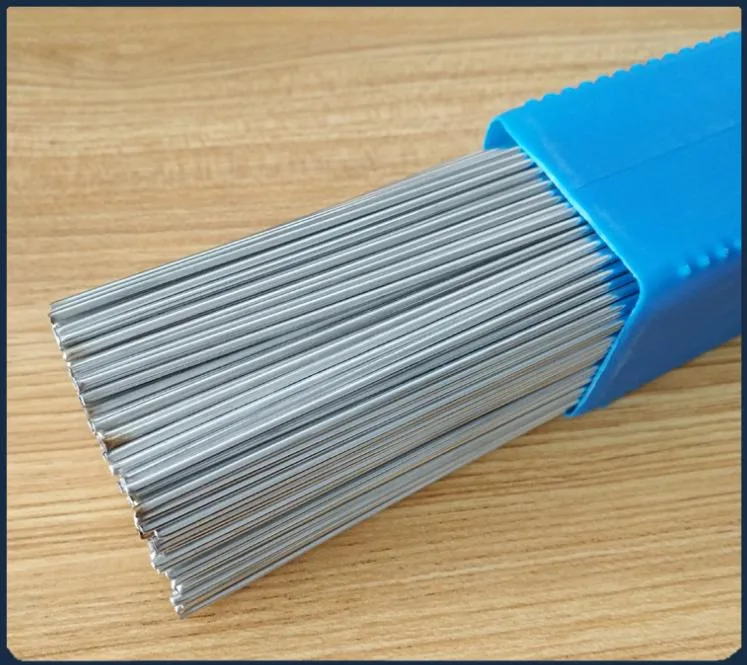

Product show:

Our factory:

Our factory:

Metal Universal Welding Wire easy to use Aluminum Flux Core Welding Wire, Solution Welding Flux-cored Rods No Flux Required, Super Low Melting Point wire

- Multiple use: the low temperature welding cored wires can be widely applied in electric power, chemistry, food using and so on, practical repair rods for argon arc welding and filling material for aluminum, stainless, galvanized steel, galvanized cast iron, copper with high strength

- No need solder powder: the multipurpose copper aluminum welding wires are practical and convenient to use, they come with internal powder and the melting point is 380 - 400 ºC, low temperature and no need to use other flux powder as the welding core and coating as salt base

- Nice performance: designed with powder cores, the copper aluminum welding rods have nice forgeability, conductivity and corrosion resistance, which can provide you with smooth welding effect, suitable for home and professional maintain work

- Size information: the universal low temperature welding core wires are approx. 2 mm/ 0.08 inches in diameter and 25 cm/ 10 inches in length, proper size for your working use and can reduce waste

Chemical composition:

| AWS Code | chemical composition(%) | |||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | |

| ER1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.06 | 0.03 |

| ER1100 | 0.95 | 0.95 | 0.05-0.20 | 0.05 | - | - | 0.10 | - |

| ER4043 | 4.5-6.0 | 0.80 | 0.30 | 0.05 | 0.05 | - | 0.10 | 0.20 |

| ER4047 | 11.0-13.0 | 0.80 | 0.30 | 0.15 | 0.10 | - | 0.20 | - |

| ER5356 | 0.25 | 0.40 | 0.10 | 0.05-0.20 | 4.5-5.5 | 0.05-0.20 | 0.10 | 0.06-0.20 |

| ER5183 | 0.40 | 0.40 | 0.10 | 0.5-1.0 | 4.3-5.2 | 0.05-0.20 | 0.25 | 0.15 |

| ER5556 | 0.1 | 0.3 | 0.05 | 0.55-8.0 | 4.7-5.2 | 0.05-0.10 | 0.09 | 0.05-0.10 |

1. Argon has good protective results and high quality welding can be obtained.

2. The arc has stable burning and shallow penetration, which is quite suitable for thin plates.

3. Easy to operate, all-position welding. One-side welding with back tormation.

4. Beautiful appearance of welding and no spatters.

AWS ER5356/ER4043

| Wire Size | Spool Size | Net Weight |

| 0.8mm 1.0mm 1.4mm 1.2mm 1.6mm | D100mm D200mm D270mm D300mm K300mm | 2kg ,6kg |

1. very low welding cost, high productivity and low electricity consumption.

2. excellent welding performance, stable arc, low spatter, easy slag removal.

3. perfect welding seam forming, small weld metal stomatal sensitivity.

4. easy operating, all position welding.

5. very low hydrogen content in the weld and lower nitrogen content, excellent crack-resistance.

6. little deformation after welding.

7. wide applicability. suitable for welding thin, medium and thick plates.

8. Suitably wide range of welding current.

Application

Applicable for single pass and multi-pass welding of carbon steel and low alloy steel and is widely used in such fields as automobile industry, construction machinery manufacturing, ship building, metallurgical and mining equipment manufacturing, building, petrochemical industry etc. Also applicable for high-speed welding of sheets and pipeline steel.

Product show:

Our factory:

Our factory: