- Overview

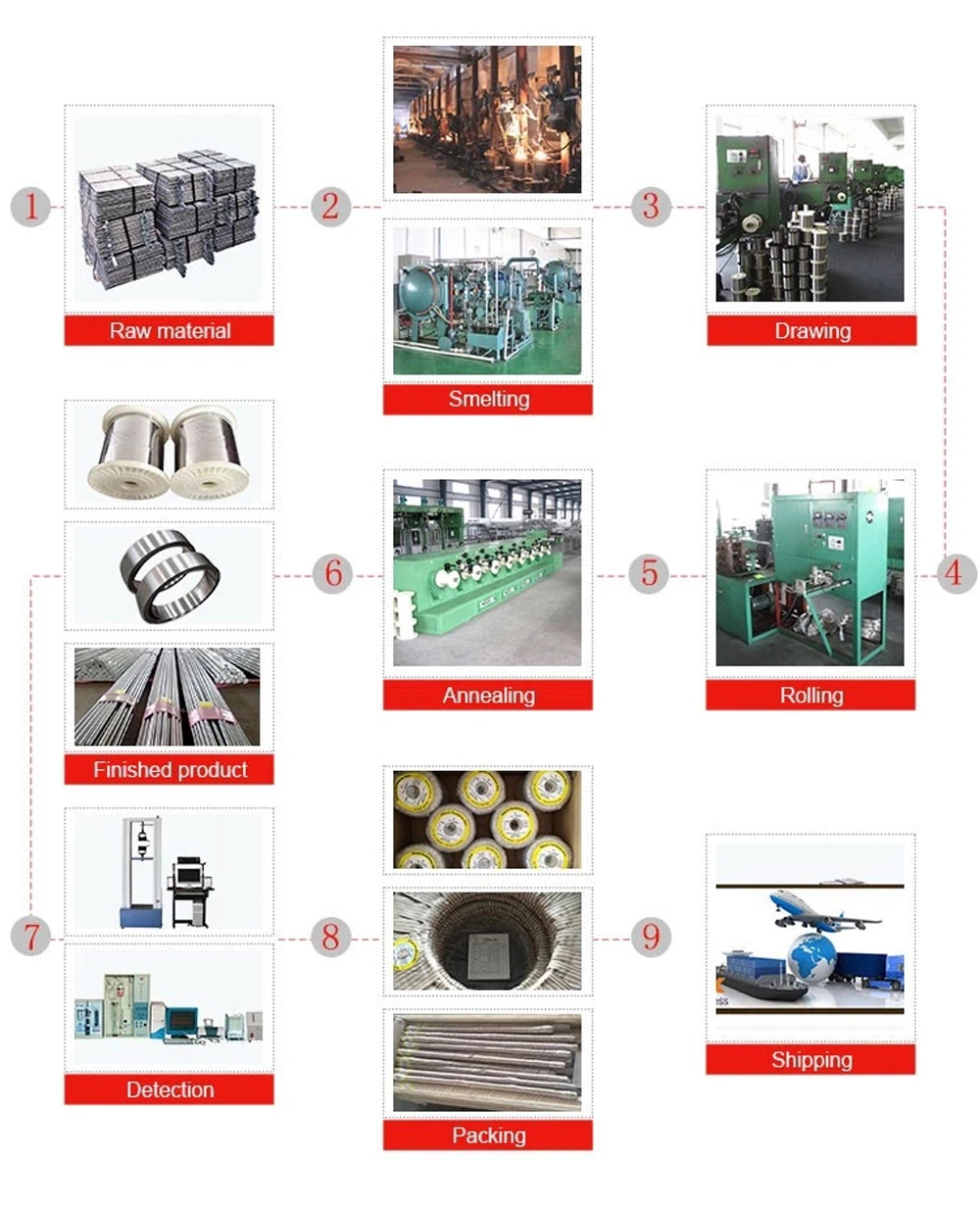

- Product Description

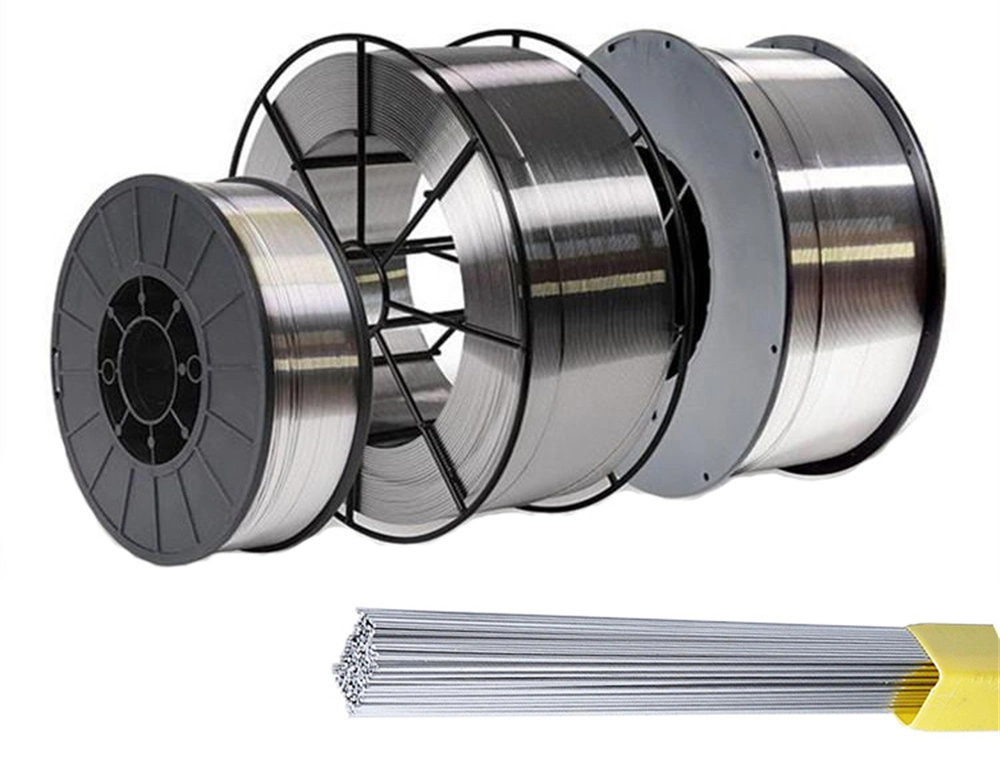

- Detailed Photos

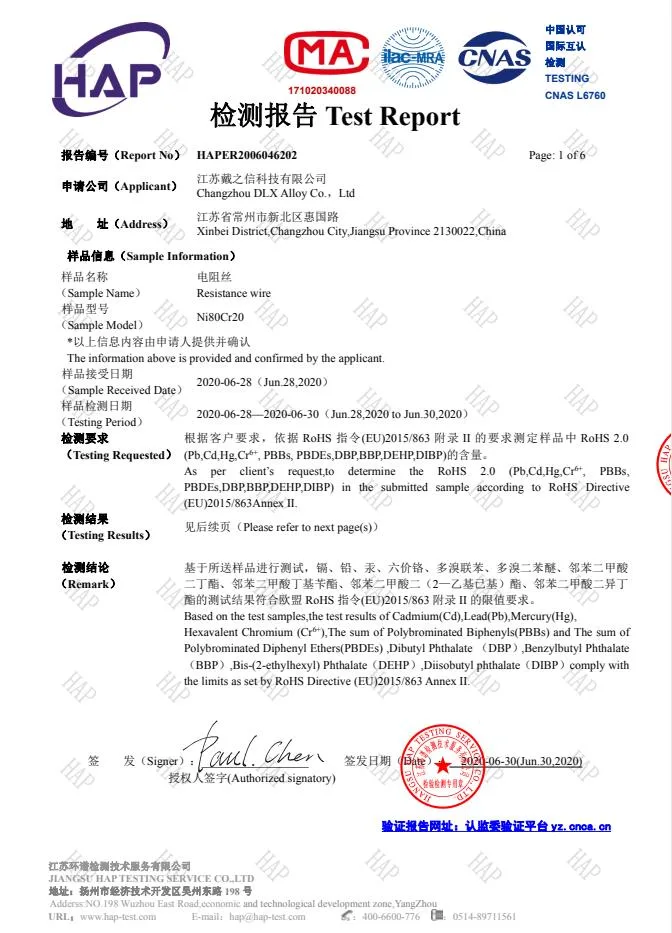

- Certifications

- Company Profile

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Nickel-based alloy welding wire has good properties of resistance to reactive gas, caustic medium, and corrosion resistance of reducing acid medium, and has the characteristics of high strength, good plasticity, hot and cold deformation, processing and welding. Therefore, it is widely used in In petrochemical, metallurgy, atomic energy, marine development, aviation, aerospace and other industries, it is a very important corrosion-resistant metal material to solve engineering corrosion problems that general stainless steel and other metals and non-metallic materials cannot solve.

Welding rod / Welding Electrode Advantages:

1. Stable arc, less splash

2. Shaped good appearance

3. Easy for removal of slag layer

4. Easy for striking arc and restriking arc.

5. Operable with low amperages on sheet metal

6. Slag control accommodates vertical down welding

| Nickel and Nickel Alloy Welding Wire | |

| Product Model(AWS) | Application |

| ERNiCr-3 | For welding 600, 601 and 800 alloys themselves, and welding dissimilar steels between stainless steel and carbon steel ERNiCrFe-7; For welding Inconel alloys within ASTM B163, 166, 167 and 168 |

| ERNiCrFe-6 | For welding of steel and Inconel, welding of steel and stainless steel and nickel-based alloys |

| ERNiCrCoMo-1 | Dissimilar welding for welding nickel-chromium-cobalt-molybdenum alloys and various superalloys |

| ERNiCrMo-3 | It is used for welding of nickel alloy, carbon steel, stainless steel and low alloy steel, mainly used for welding of 625, 601, 802 alloy and welding of 9% nickel alloy |

| ERNi-CI | Industrial pure nickel for welding malleable and grey cast iron |

| ERCuNi | For welding of 70/30, 80/20, 90/10 copper-nickel alloys |

| ERNiCu-7 | For welding nickel copper alloys B127, 163, 164 and 165 etc. |

| ERNi-1 | For welding of pure nickel castings and forgings such as alloys within ASTM B160, 161, 162, 163 |

| ERNiFeMn-CI | For welding of nodular cast iron, ductile iron, malleable cast iron and grey cast iron to itself or to stainless steel, carbon steel, low alloy steel and various nickel alloys |

| ERNiCrMo-4 | For welding nickel-chromium-molybdenum alloy itself, or welding nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys |

| ERNiCrMo-11 | It is used for welding of nickel-chromium-molybdenum alloy itself, or welding of nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys, and can also be used for surfacing welding of nickel-chromium-molybdenum alloy and steel welding seam |

| ERNiCrMo-13 | For welding low carbon nickel chromium molybdenum alloys |

When classified by their chemical composition characteristics, there are mainly nickel, nickel-copper alloys, nickel-molybdenum

(nickel-molybdenum-iron) alloys, nickel-chromium (nickel-chromium-iron) alloys, nickel-chromium-molybdenum (including

nickel-chromium-molybdenum alloys and nickel-chromium-molybdenum-copper alloys) ) and nickel-iron-chromium (that is,

iron-nickel-based alloys) and other categories.

Pure nickel wire ERNi-1 is used for welding 200, 201 nickel alloys and nickel-plated steel plates; welding of steel and nickel

dissimilar materials; surfacing of steel. Nickel copper wire ERNiCu-7 welding of Monel 400 alloy itself; and welding of Monel 400 alloy and steel; used for surfacing of steel.

Nickel-chromium wire ERNiCrFe-3 for welding dissimilar materials in creep-resistant joints; - welding of austenitic, ferritic

steels and high-nickel alloys, welding of 9% nickel-containing alloy steels ERNiCrFe-7 for alloys welding and surfacing of steel, especially for the construction of nuclear reactors. Nickel-chromium-molybdenum welding wire ERNiCrMo-3 INCONEL625, INCONEL825, INCONEL25-6Mo and MONEL400 alloy welding; - welding between ultra-high strength austenitic steel and INCOLOY020 alloy; welding between nickel-based alloys and stainless steel dissimilar materials; steel stacking weld.

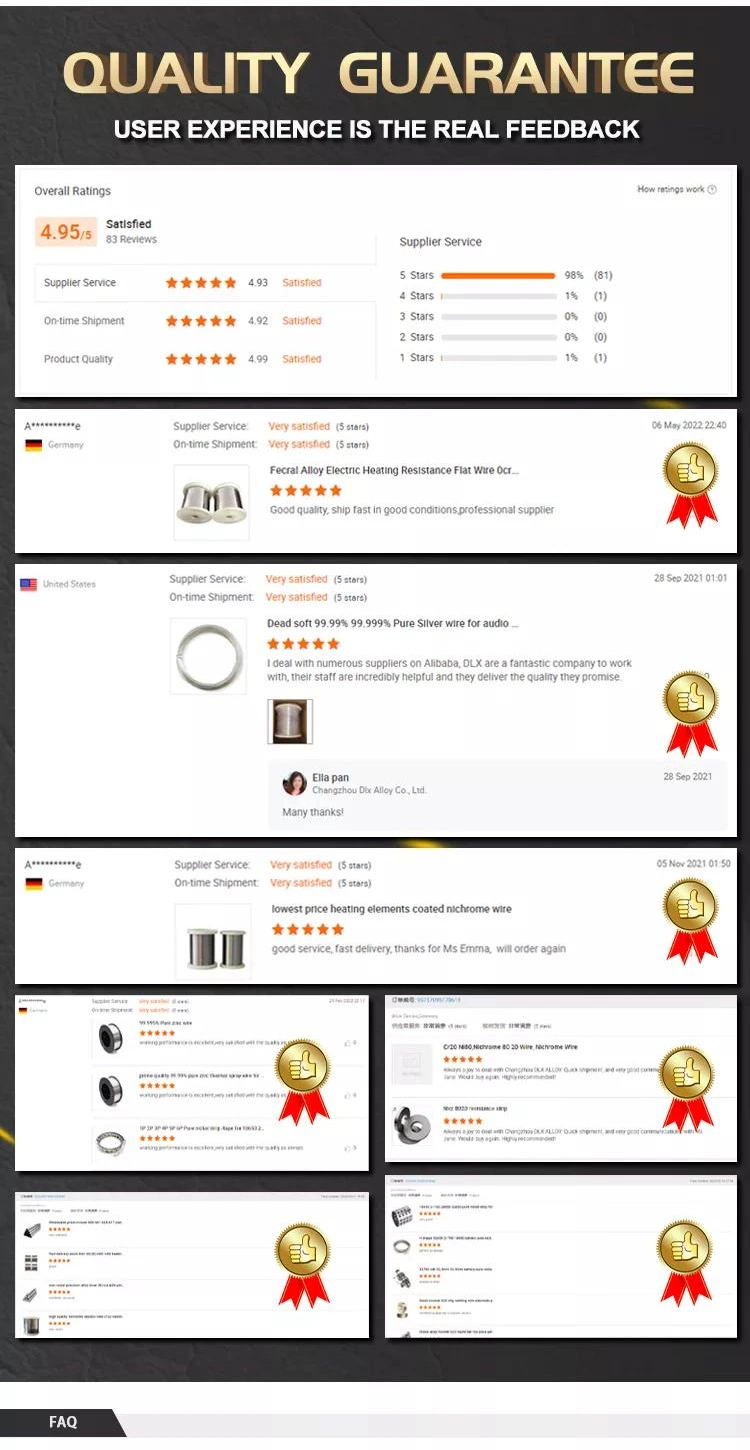

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples.

2, We can provide the products within a week after payment.

3, Wecan provide sample of the products customer need.

4, We always insist on "Quality first, Customer first" as our business philosophy.

Question: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Question: could we visit your factory?

Answer: Sure, factory visit is warmly welcome.