- Overview

- Product Description

- Chemical Composition (%)

- Mechanical property

- Available Size

- Titanium wire tolerance

- product application

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

| Standard | ASTM B863, ASTM B348, ASTM F67, ASTM F136, etc. |

| Grade | Gr1, Gr2, Gr3, Gr5, Gr23, etc. |

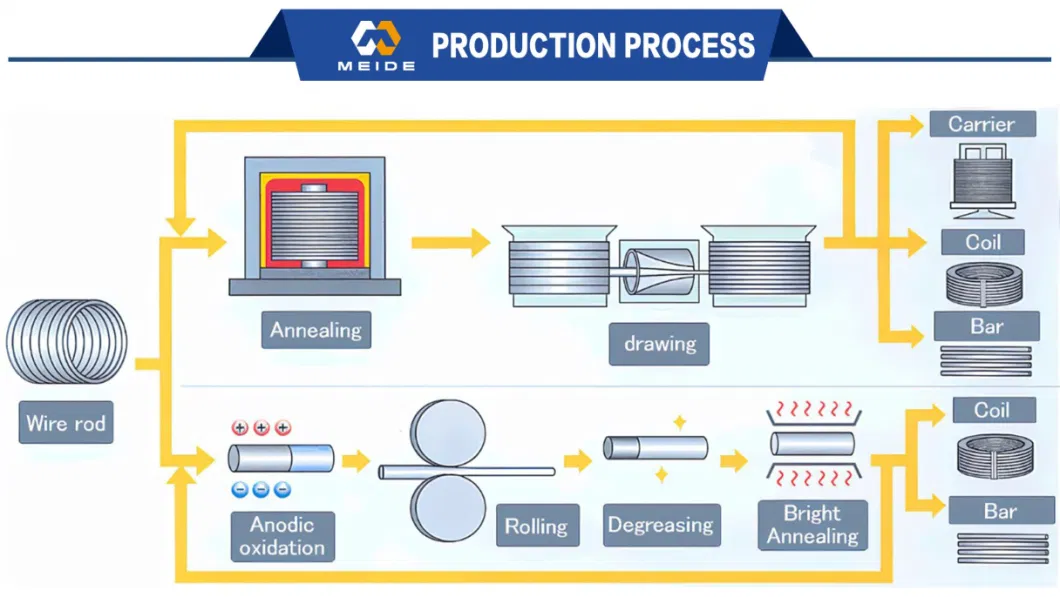

| Technique | Hot Rolled, Cold Rolling, Annealed |

| Straight | Dia.:1.0mm-5.0mm ( tolerance: +/-0.05mm ) |

| Coiled | Dia.:0.03mm-5.0mm ( tolerance: +/-0.05mm ) |

| Length | Coils or Customers' Requests |

| Surface | Black, Pickled, Polished ( For Dia. >1mm ) |

Low Density and High Specification Strength

Excellent Corrosion Resistance

Good resistance to effect of heat

Excellent Bearing to cryogenic property

Nonmagnetic and Non-toxic

Good thermal properties

Low Modulus of Elasticity

Testing:

Room Temperature Tensile

Bend Testing

Metallography (General)

Micro-hardness

Near Surface Examinations

Hardness Testing

Meet Specifications AMS, ASTM, MIL, DIN

| Grade | N | C | H | Fe | O | Al | V | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5~6.75 | 3.5~4.5 | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5~3.5 | 2.0~3.0 | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.6~0.9 | bal |

| Grade | Tensile strength(min) | Yield Strength(min) | Elongation(%) | ||

| ksi | MPa | ksi | MPa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr3 | 65 | 450 | 55 | 380 | 18 |

| Gr4 | 80 | 550 | 70 | 483 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| Product Names | Dimensions(mm) | Grade | Standards |

| Titanium wire | Φ(0.03~7.0)×L | GR1,GR2,GR3,GR4 | ASTM B863 |

| Titanium alloy wire | Φ(0.1~7.0)×L | GR5,GR7,GR9,GR12,GR23 | ASTM B863 |

| Titanium welding wire | Φ(0.1~7.0)×L | ERTi-1, ERTi-2, ERTi-3,ERTi-4,ERTi-5,ERTi-7, ERTi-9, ERTi-12, ERTi-23 | AWS A5.16 |

1.At present, more than 80% of titanium and titanium alloy wires are used as welding wires, such as welding and welding pipes for various titanium equipment

2.because of its excellent corrosion resistance, titanium wire has been widely used in the chemical industry, pharmaceutical industry, paper industry and other industries, can be woven into a mesh as sea water filter, pure water filter, chemical filter, etc.

3. titanium and titanium alloy wire due to its good comprehensive performance, it is also used to make fasteners, bearing members, springs and so on.

4.In the medical and health industry, titanium and titanium alloy wires are used to manufacture medical devices

5.Some titanium alloy wires with shape memory, such as titanium-nickel alloy wires, are used to make satellite dishes and eyeglass frames.

6.Titanium and titanium alloy wires are used to make electrodes in electroplating and water treatment industries

| Permissible Variations in Size for Titanium Wire | ||

| Specified Diameter,in. (dimension if shape wire) | Variation,in. | |

| Wire as Coil or on Spools | Cut Straight LengthsA | |

| 0.020 to 0.045,incl | ±0.001 | ±0.0015 |

| over 0.045 to 0.062,incl | ±0.0015 | ±0.002 |

| over 0.062 to 0.060,incl | ±0.002 | ±0.0025 |

| over 0.090 to 0.187,incl | ±0.003 | ±0.003 |

| over 0.187 to 0.250 | ±0.004 | ±0.004 |

| Length tolerance for cut lengths is ±0.25 in. for lengths up to and including 36 in. | ||

Aerospace alloys and applications

Medical implants

Automotive applications

Piercing & Accessory

Optical frames

Surgical instruments

Architectural applications

Cladding to other materials

Bolts & Nuts

Netting in corrosion

1. Carefully check the quantity and quality of equipment before packing.

2. Good packed by plastic wrap.

3. Iron Frame, Suitable for land transport and sea freight.

4. Fittings and spare parts are packed in a wooden pallet.

5. Add labels and shipping marks.

1.Are you a manufacturer or a trader?

We're a manufacturer with more than years of professional production experience.

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

3.Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

4.Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

5.What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

6.How long is your delivery time? Which ports are accepted for delivery?

Normally 30days after payment, and we promise we will deliver as soon as we can. It can be delivered from Qingdao, Tianjin, Shanghai, Guangzhou and other ports.

7.How can we get your price ?

A. We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts