Basic Info.

Product Description

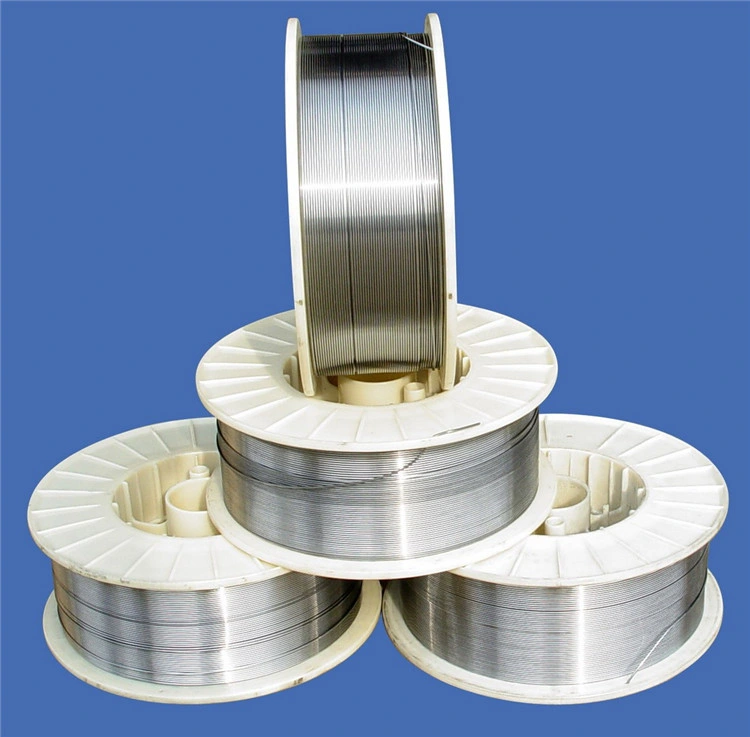

Prime Stainless Steel Flux Cored Welding Wires

Our high grade Stainless Steel Welding Wire collaborated together to form a complete range of Stainless Steel Welding Wires. For the welding purpose many user believes in the efficiency of Stainless Steel Welding Wire as it shows the ability to not corrode or rust easily. Stainless Steel Welding Wire are used for its fabrication purposes and are used in the welding functioning where both the features of steel as well as corrosion resistance are required. To check their authenticity, they are passed through various quality parameters, which also help them to maintain their quality.

| TIG and MIG stainless steel welding wire composition | ||||||||||

| YB5092-2005 | AWS | chemical composition % | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | |||

| H08Cr20Ni9Mn7Si | ER307Si | 0.075 | 0.78 | 6.70 | 0.022 | 0.010 | 19.8 | 8.80 | ||

| H06Cr21Ni10 | ER308 | 0.045 | 0.45 | 1.90 | 0.020 | 0.009 | 20.8 | 9.80 | ||

| H00Cr21Ni10 | ER308L | 0.02 | 0.32 | 1.90 | 0.011 | 0.006 | 20 | 10.2 | ||

| H06Cr21Ni10Si | ER308Si | 0.045 | 0.85 | 1.50 | 0.022 | 0.010 | 20.8 | 9.80 | ||

| H06Cr24Ni13 | ER309 | 0.06 | 0.45 | 1.90 | 0.019 | 0.009 | 24.3 | 13.20 | ||

| H06Cr24Ni13Si | ER309Si | 0.06 | 0.79 | 1.95 | 0.019 | 0.009 | 24.7 | 13.20 | ||

| H03Cr24Ni13 | ER309L | 0.020 | 0.42 | 1.80 | 0.020 | 0.010 | 24.8 | 13.2 | ||

| H03Cr24Ni13Si | ER309LSi | 0.018 | 0.80 | 1.70 | 0.020 | 0.010 | 23.5 | 13.50 | ||

| H21Cr16Ni35 | ER330 | 0.20 | 0.38 | 1.50 | 0.022 | 0.010 | 16.5 | 34.5 | ||

| H06Cr19Ni12Mo2 | ER316 | 0.04 | 0.40 | 1.90 | 0.020 | 0.010 | 19.5 | 11.80 | 2.30 | |

| H06Cr19Ni12Mo2Si | ER316Si | 0.05 | 0.70 | 1.92 | 0.020 | 0.010 | 19.5 | 11.80 | 2.30 | |

| H03Cr19Ni12Mo2 | ER316L | 0.019 | 0.38 | 1.80 | 0.018 | 0.010 | 19.8 | 12.20 | 2.50 | |

| H03Cr19Ni12Mo2Si | ER316LSi | 0.06 | 0.85 | 1.70 | 0.022 | 0.010 | 18.8 | 12.60 | 2.40 | |

| H03Cr17Ni14Mo3 | ER317L | 0.02 | 0.38 | 1.80 | 0.020 | 0.010 | 18.8 | 13.80 | 3.60 | |

| H08Cr19Ni12Mo2Nb | ER318 | 0.06 | 0.42 | 1.50 | 0.022 | 0.010 | 18.5 | 11.80 | 2.30 | |

| H07Cr20Ni34Mo2Cu3Nb | ER320 | 0.06 | 0.40 | 1.00 | 0.022 | 0.010 | 19.8 | 33.3 | 2.80 | Nb0.7 |

| H02Cr20Ni34Mo2Cu3Nb | ER320L | 0.018 | 0.33 | 1.50 | 0.013 | 0.010 | 19.8 | 33.60 | 2.50 | Nb0.35 |

| H08Cr20Ni10Ti | ER321 | 0.06 | 0.45 | 1.50 | 0.022 | 0.010 | 20.8 | 9.80 | Ti9×C-1.0 | |

| H08Cr21Ni10Nb | ER347 | 0.055 | 0.48 | 1.80 | 0.021 | 0.008 | 20.8 | 9.80 | Nb1×C-1.0 | |

| H12Cr26Ni21 | ER310 | 0.09 | 0.50 | 1.66 | 0.020 | 0.010 | 25.5 | 20.50 | ||

| H02Cr20Ni25Mo4Cu | ER385 | 0.020 | 0.30 | 1.50 | 0.018 | 0.010 | 20.2 | 24.80 | 4.80 | Cu 1.80 |

| H03Cr22Ni9Mo3N | ER2209 | 0.022 | 0.50 | 0.90 | 0.020 | 0.010 | 22.5 | 8.80 | 3.30 | N0.08-0.20 |

| H04Cr25Ni5Mo3Cu2N | ER2553 | 0.027 | 0.50 | 1.00 | 0.025 | 0.015 | 24.8 | 5.50 | 3.20 | N0.1-0.25 |

| H15Cr29Ni9 | ER312 | 0.09 | 0.38 | 1.50 | 0.022 | 0.010 | 29.5 | 8.50 | ||

| H03Cr24Ni13MoL | ER309LMo | 0.023 | 0.45 | 1.50 | 0.022 | 0.010 | 23.8 | 13.20 | 2.20 | |

| H05Cr17Ni4Cu4Nb | ER630 | 0.04 | 0.39 | 0.50 | 0.022 | 0.010 | 16.5 | 4.80 | Cu;3 Nb;0.28 | |

| H08Cr26Ni5Mo2 | ER453s | 0.06 | 0.30 | 0.40 | 0.022 | 0.010 | 25.8 | 4.80 | 2.10 | |

| H08Cr21Ni10Mn6 | 0.06 | 0.35 | 5.50 | 0.022 | 0.010 | 20.8 | 9.80 | |||

| H05Cr22Ni11Mn6Mo3VN | ER209 | 0.04 | 0.40 | 4.50 | 0.022 | 0.010 | 21.5 | 10.80 | 2.20 | N;0.20 V;0.18 |

The Advantages :

1. Own production plant

2. High corrosion and mechanical property

3. Good Welding Performance: no clearing slag, low welding spatter, smooth surface, high welding efficiency, stable filling rate, etc.

4. welding wire without any joints.

5. Production Capacity: 8000 tons per year

6. Short Delivery Time: Generally 7 days

7. We have many experienced professionals to research and develop welding wires according to customers' specified chemical compositions.

8. We can recommend proper welding wires and provide technical solutions based on working conditions.

9. on site inspection and third party inspection are available.

10. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously.

Packaging & Shipping

Packing Details :25KG carton, 150-350kgs/drum, Steel Pallet, film, Customized Package

Packing Size: 1.15m*1.15m*0.88m, 1.15m*0.58m*0.88m, customized

Delivery Time: Generally 7 days

As one modern enterprise and specially engaged in developing and manufacturing Submerged Arc Welding Consumables including Welding Flux, S.A.W wires, Hardfacing Welding Wires etc. These products are widely used in many manufacturing and welding fields such as structural steel fabrication, ships building, LPG cylinder, engineering machinery, various mill roller hardfacing, big diameter SAW pipe, pressure vessels, offshore welding and so on.

The company has passed ISO9001 national qualification system certificate; classification society anthentication of several countries such as China, America, Japan; AAA standardization good behavior enterprise authentication. Our company always put integrity in the first place and has titled as Chinese welding industry AAA grade credit enterprise by Chinese Welding Association.

International Business Department

Andy Ren / Sales Manager