- Overview

- Product Description

- Product Parameters

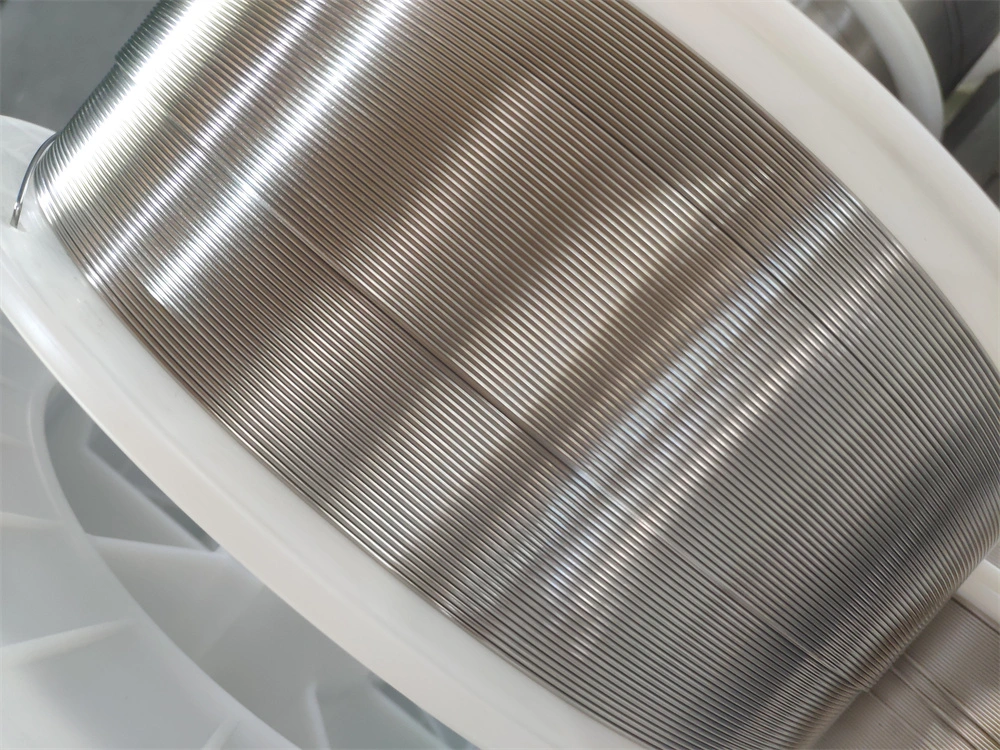

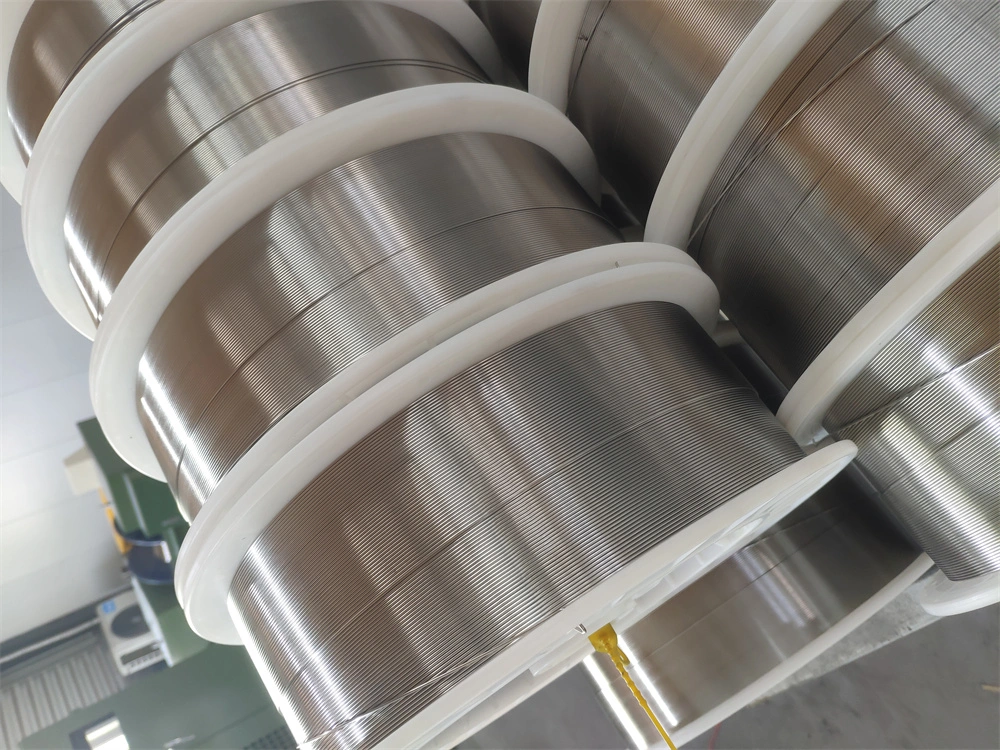

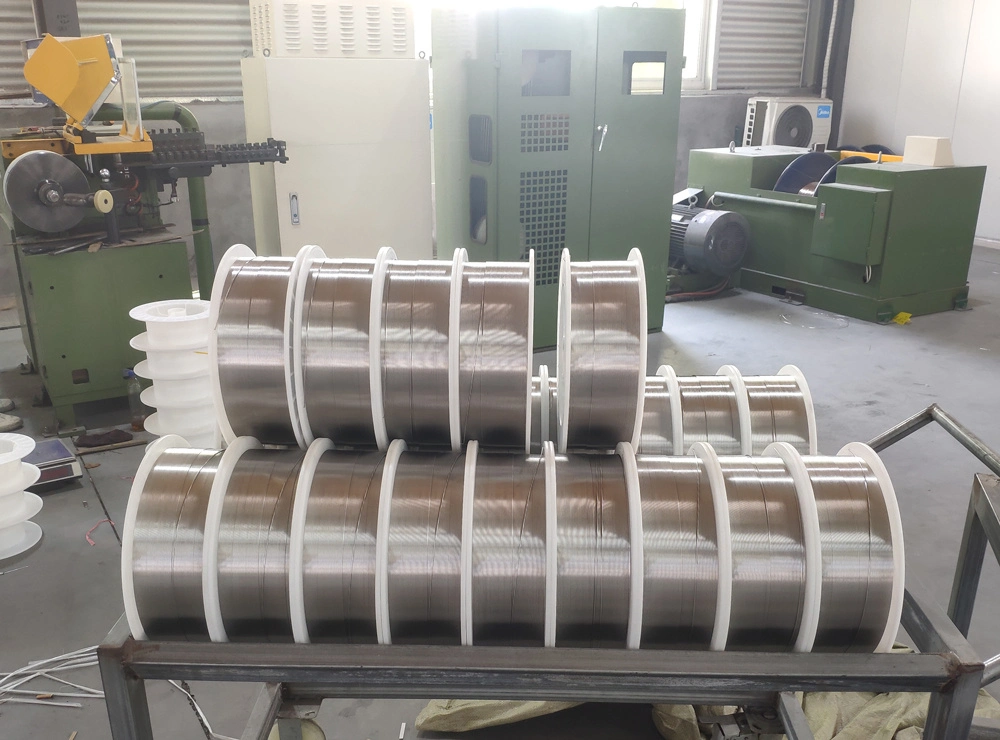

- Detailed Photos

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Inconel 625 welding wire ERNiCrMo-3 material is suitable for the welding of nickel based alloys such as Inconel 625 and Incoloy 825, but also for dissimilar welds, e. G. Between stainless and nickel-based alloys and mild steel.

Standard: AWS A5.14 EN18274 ,ASME II, SFA-5.14, ERNiCrMo-3

Size:0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM

Form:MIG(15kg/spool), TIG(5kg/box)

Applications:used for welding the INCONEL ALLOY 600/825/25-6MO, and other stainless steel with Mo by the way of gas metal arc welding,tungstun-inert-gas arc welding.

Weling series:ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1

| Type | Standard | Manin chemcial composition % | Typical application |

| Nickel welding wire | A5.14 ERNi-1 | Ni ≥ 93 Ti3 Al1 Cr-- Mo-- | ERNi-1 is used for GMAW, GTAW and ASAW welding of Nickel 200 and 201, joining these alloys to stainless and carbon steels, and other nickel and copper-nickel base metals. Also used for overlaying steel. |

| NiCuwelding wire | A5.14 ERNiCu-7 | Ni 65 Cr-- Mo-- Ti2 Other: Cu | ERNiCu-7 is a copper-nickel alloy base wire for GMAW and GTAW welding of Monel alloys 400 and 404. Also used for overlaying steel after first applying Layer of 610 nickel. |

| CuNi welding wire | A5.7 ERCuNi | Ni 30 Cr-- Mo-- Other: Cu | ERCuNi is used for gas metal and gas tungsten arc welding. Can also be used by oxy-fuel welding of 70/30, 80/20, and 90/10 copper nickel alloys. A barrier layer of nickel alloy 610 is recommended prior to overlaying steel with GMAW weld process. |

| NiCr welding wire | A5.14 ERNiCrFe-3 | Ni≥ 67 Cr 20 Mo--- Mn3 Nb2.5 Fe2 | Type ENiCrFe-3 electrodes are used for welding of nickel-chromium-iron alloys to themselves and for dissimilar welding between nickel-chromium-iron alloys and steels or stainless steels. |

| A5.14 ERNiCrFe-7 | Ni: Rest Cr 30 Fe 9 | Type ERNiCrFe-7 is used for gas-tungsten-arc and gas-metal-arc welding of INCONEL 690. | |

| NiCrMo welding wire | A5.14 ERNiCrMo-3 | Ni≥ 58 Cr 21 Mo 9 Nb3.5 Fe ≤1.0 | ERNiCrMo-3 is used primarily for gas tungsten and gas metal arc and matching composition base metals. It is also used for welding Inconel 601 and Incoloy 800. It can be used to weld dissimilar metal combinations such as steel, stainless steel, Inconel and Incoloy alloys. |

| A5.14 ERNiCrMo-4 | Ni Rest Cr 16 Mo 16 W3.7 | ERNiCrMo-4 is used for welding nickel-chromium-molybdenum base materials to itself, steel and other nickel base alloys and for cladding steel. | |

| A5.14 ERNiCrMo-10 | Ni Rest Cr 21 Mo 14 W3.2 Fe 2.5 | ERNiCrMo-10 is used for welding nickel-chromium-molybdenum base materials to themselves, steel and other nickel base alloys, and for cladding steels. Can be used to weld duplex, super duplex stainless steels. | |

| A5.14 ERNiCrMo-14 | Ni Rest Cr 21 Mo 16 W3.7 | ERNiCrMo-14 is used for gas-tungsten-arc and gas-metal-arc welding of duplex, super-duplex and super-austenitic stainless steels, as well as nickel alloys such as UNS N06059 and N06022, INCONEL alloy C-276, and INCONEL alloys 22, 625, and 686. |

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples.

2, We can provide the products within a week after payment as long as have stock.

3, We can provide sample of the products customer need.

4, We always insist "Quality first, Customer first" as our business philosophy.

1. Question: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Answer: Sure, factory visit is warmly welcome.

5. Question: Do you provide samples?

Answer: Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.