Basic Info.

Model NO.

E316L-16

Length

300-500mm

Welding Core Type

Stainless Steel

Electrode Coating Type

Titanium

Slag Characteristic

Acidic

Stainless Steel Welding Rod Type

Chromium Stainless Steel

Function

Surfacing Electrode, Low Hydrogen Type Electrode, Hardfacing Electrode, High Efficient Iron Powder Electrode, Gravity Electrode, Moisture-Proof Electrode

Welding Power

DC

Advantage1

Small Splash

Advantage2

Excellent Welding

Advantage3

Smooth Surface

Certification

RoHS / ISO9001:2008 / ISO900014001:

Application

Mild Steel Structures

Transport Package

5kg/Box

Specification

2.0-5MM

Trademark

xunzhuo

Origin

China

Production Capacity

5000 Ton/Month

Product Description

Hunan Xunzhuo Import & Export Co., Ltd.

E316L-16 Stainless Steel Welding Electrode/Rod

Specification

Features & Applications

It is suitable for welding facilities of synthetic fibre or urea, as well as for similar stainless steel structures. Also it could be used for welding structures made by category of chromium stainless steels that could not be PWHT or for welding dissimilar steels and ply steels. The weld metal has good performance of resistance to corrosion, heat and crack defect.It is suitable for welding facilities of synthetic fibre or urea, as well as for similar stainless steel structures. Also it could be used for welding structures made by category of chromium stainless steels that could not be PWHT or for welding dissimilar steels and ply steels. The weld metal has good performance of resistance to corrosion, heat and crack defect.

ATTENTION:

1.Electrode must be approved by 320-350 ºC for 1 hour before welding, dry the electrode when use it.

2. The rust, oil, water and other impurities of the weld must be removed before welding.

3.Recommended DC power supply, because AC welding has a shallow penetration, the current should not be too large, in order to avoid the coating redness and cracking.

4. To minimize the amount of heat input and welding electrode oscillating amplitude shoulds not be too big.

5.Preheat and interlayer-temperature should remain below 150 ºC

| Chemical Composition Deposited Metal (%) | ||||||||

| C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| ≤0.04 | 0.5~2.5 | ≤0.90 | 17~20 | 11~14 | ≤0.03 | ≤0.04 | 2.0~3.0 | ≤0.75 |

| Mechanical Properties of Deposited metal | ||||||||

| Test Item | Tensile Strength ós (Mpa) | Elongation δ5(%) | ||||||

| Guranteed | ≥490 | ≥30 | ||||||

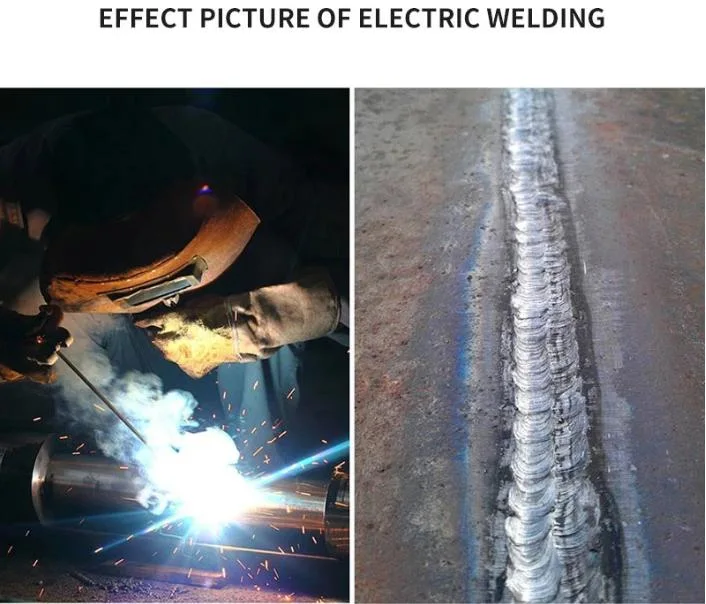

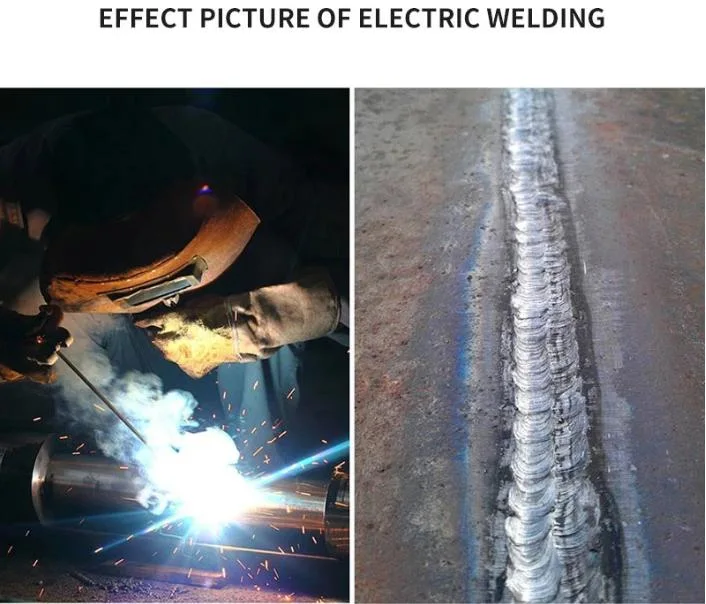

Detailed Photos

Company Profile

Hunan Xunzhuo Import & Export Co., Ltd. was established in 1998. Its predecessor is Hunan Welding Material Factory. It is one of the earliest professional welding material manufacturers in China. The "XUNZHUO" brand has a high reputation in the domestic market. In order to better serve the international market, the company established the foreign trade department "Hunan Xunduo Import and Export Co., Ltd." in 2010, which is mainly responsible for the import and export business of the company!

Headquartered in Changsha City, Hunan Province, the company currently invests in Tianjin, Shijiazhuang, Qingdao, Dezhou,

Changzhou, Shenzhen and other regions to establish a wholly-owned or controlled subsidiary of the main welding materials and products, including the company headquarters in Changsha The area is nearly 100,000 square meters.

The company's main products are welding rods (carbon steel electrode, low alloy steel electrode, stainless steel electrode,

surfacing electrode, cast iron electrode, nickel and nickel alloy electrode, copper and copper alloy electrode), welding wire (for MAG, MIG, TIG gas) Protective welding solid wire, flux cored wire, non-ferrous metal wire, submerged arc welding wire and gas welding wire), flux, welding machine (MMA, MIG MAG, CUT series), welding torch and various welding accessories.

The company's main products are obtained by China Classification Society (CCS), Lloyd's Register of Shipping (LR), American Ship Survey Association (ABS), French Bureau of Shipping (BV), and German Suede Classification Society (GL). Authorized by the Norwegian Classification Society (DNV), the Japan Maritime Association (NK), the Korean Classification Society (KR), the Indonesian Classification Society (BKI) and the Canadian Welding Authority (CWB).

In the future, the company will actively implement relevant diversified high-tech breakthroughs closely related to the welding process, and concentrate on integrating welding materials, welding equipment and welding application technology resources, and strive to become a world-famous "welding expert".

Changzhou, Shenzhen and other regions to establish a wholly-owned or controlled subsidiary of the main welding materials and products, including the company headquarters in Changsha The area is nearly 100,000 square meters.

The company's main products are welding rods (carbon steel electrode, low alloy steel electrode, stainless steel electrode,

surfacing electrode, cast iron electrode, nickel and nickel alloy electrode, copper and copper alloy electrode), welding wire (for MAG, MIG, TIG gas) Protective welding solid wire, flux cored wire, non-ferrous metal wire, submerged arc welding wire and gas welding wire), flux, welding machine (MMA, MIG MAG, CUT series), welding torch and various welding accessories.

The company's main products are obtained by China Classification Society (CCS), Lloyd's Register of Shipping (LR), American Ship Survey Association (ABS), French Bureau of Shipping (BV), and German Suede Classification Society (GL). Authorized by the Norwegian Classification Society (DNV), the Japan Maritime Association (NK), the Korean Classification Society (KR), the Indonesian Classification Society (BKI) and the Canadian Welding Authority (CWB).

In the future, the company will actively implement relevant diversified high-tech breakthroughs closely related to the welding process, and concentrate on integrating welding materials, welding equipment and welding application technology resources, and strive to become a world-famous "welding expert".