Basic Info.

Model NO.

Electrical Lead Wire Solder

Percentage of Tin

From 12 to 63

Percentage of Lead

From 35 to 86

Percentage of Flux

2 Percents as Standard or Customized

Wire Diameter

0.6mm-3.2mm

Weight

50g-1000g

Packing

Spool

Alloy Name

20sn80pb

Alloy Number

20 80

Alloy Composition

20% Tin and 80% Lead

Core

Rosin Core

Diameter

1.8mm

Weight Per Reel

1 Lb

Usage

for Electrical

Usage 2

for Radiator Welding

Usage 3

for Electronics Welding

Transport Package

Spool

Specification

Tin Lead Solder

Trademark

XF Solder or OEM

Origin

Foshan, China

HS Code

831130000

Production Capacity

10800 Ton / Year

Product Description

1.8mm Rosin Core Electrical Lead Wire Solder 1 Lb 20sn80pb

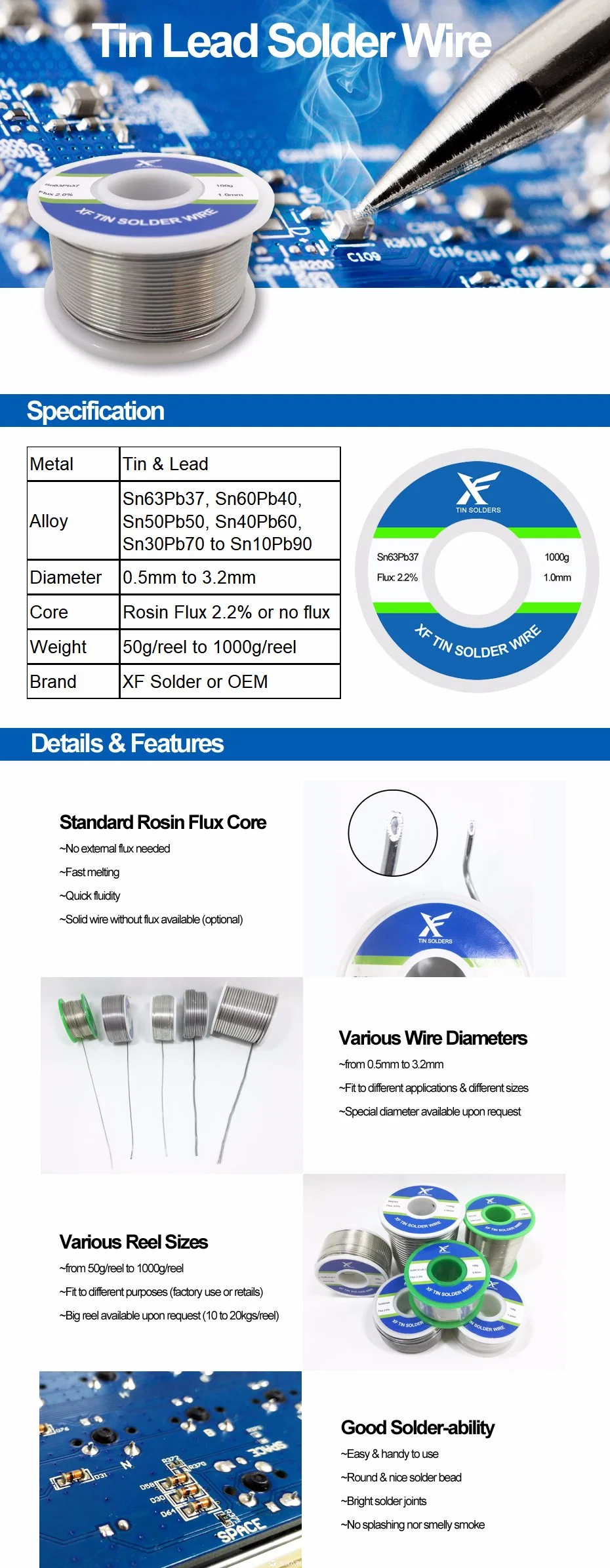

Tin Lead Solder Wires:

Our company provides Tin Lead Solder Wires with a variety of alloy composition , content and size of the diameter of pharmaceutical different specifications tin for customer choice.

Features of Tin Lead Solder Wire Sn63Pb37 63 37:

Features of Tin Lead Solder Wire Sn63Pb37 63 37:

Applications of Tin Lead Solder Wire Sn63Pb37 63 37:

Electronics Production: Solder Wire 63 37 is used in electronics assembly, ensuring reliable connectivity in PCBs and components. Such televisions, smartphones, laptops and computers

refrigerators, washing machines, LED lighting.

Industrial Devices: Solder wire Sn63Pb37 is used for assembly of electrical parts inside the industrial devices, such as solar panels, machine control board, auto car components etc.

Repairs and DIY projects: It's also used for repairing of electronics or electrical devices, or for hobbyists to use for their DIY projects.

How to use Tin Lead Solder Wire Sn63Pb37 63 37:

Manual soldering: we need solder irons or soldering stations to conduct the manual soldering. It's flexible way of manufacturing that allows workers to carry out the soldering work basing on requirements.

Automatic soldering: Ideal for mass production, automatic soldering machines feed and melt the solder wire, ensuring standardized joints.

Precaution for using Tin Lead Solder Wire Sn63Pb37 63 37:

Use in a Well-Ventilated Area: Always solder in a well-ventilated space, such as a fume hood or near an open window, and use exhausting fan. Proper ventilation helps to dissipate harmful fumes and reduce the risk of inhaling lead vapors.

Wear Personal Protective Equipment (PPE): Consider wearing appropriate personal protective equipment, including safety glasses, gloves, and a lab coat or apron, to minimize skin and eye contact with solder and flux.

Avoid Ingestion and Hand-to-Mouth Contact: Never eat, drink, or smoke while working with leaded solder. Wash your hands thoroughly after handling solder and before eating or touching your face.

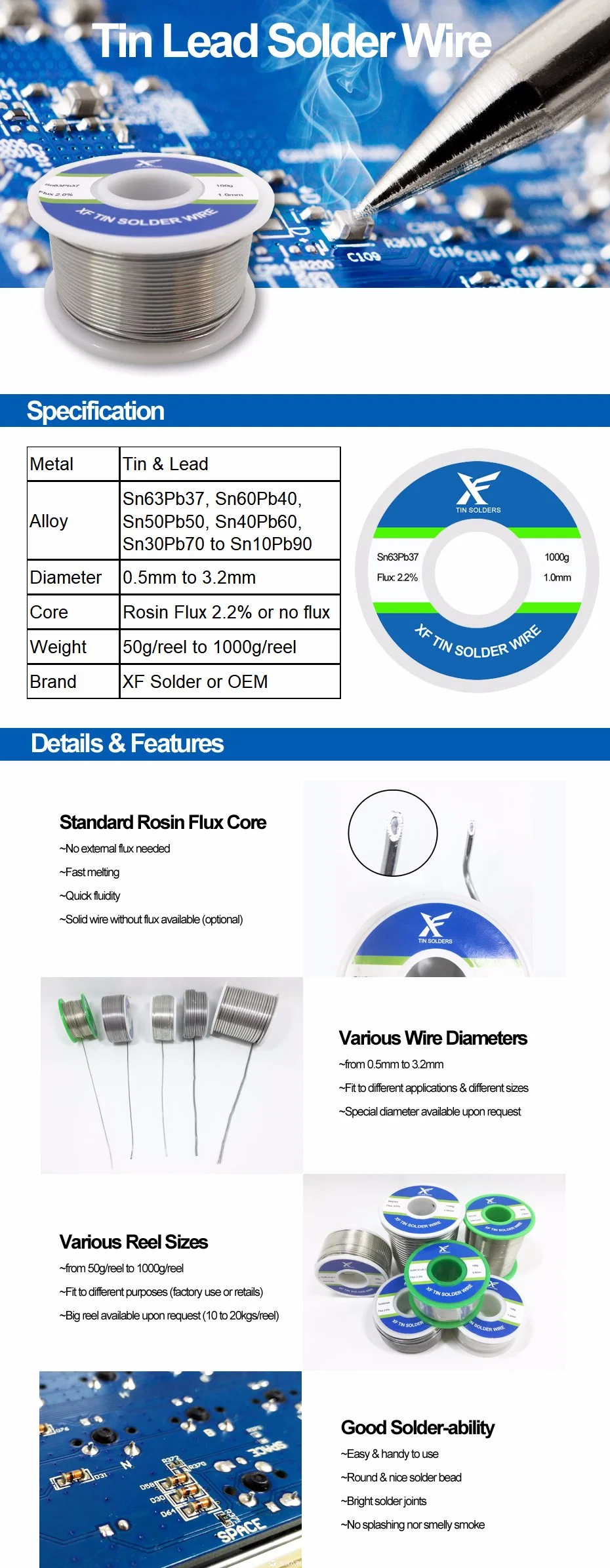

Tin Lead Solder Wires:

Our company provides Tin Lead Solder Wires with a variety of alloy composition , content and size of the diameter of pharmaceutical different specifications tin for customer choice.

Features of Tin Lead Solder Wire Sn63Pb37 63 37:

Features of Tin Lead Solder Wire Sn63Pb37 63 37: | Eutectic Alloy The melting point and solidifying point of solder wire 63 37 is same, there is no plastic range for this alloy. That makes it very easy to use even for beginners. | Excellent Wetting & Fluidity Solder Wire 63 37 has exceptional wetting and flowing properties, making the solder well flow and spread on the soldered components to get nice solder joints. | |

| Flux Core It contains neutral rosin flux core and there is no need to apply flux in separate during soldering. The rosin flux core helps the solder to fast melt and evenly flow to cover the soldering area. | Low Melting Temperature The melting point is only 183ºC which is lower than most of other solder alloys. It's easy to melt and handy to use. | |

| Affordable Price Comparing to lead free solder wires, solder wire Sn63Pb37 is at least 30% cheaper. That greatly reduce the manufacturing cost of electronics. | Flexible Packing This solder wire comes in both small package like 100g/roll up to big package like 1kg/roll. That provides flexibility for customers to select an amount without wastage. |

Applications of Tin Lead Solder Wire Sn63Pb37 63 37:

Electronics Production: Solder Wire 63 37 is used in electronics assembly, ensuring reliable connectivity in PCBs and components. Such televisions, smartphones, laptops and computers

refrigerators, washing machines, LED lighting.

Industrial Devices: Solder wire Sn63Pb37 is used for assembly of electrical parts inside the industrial devices, such as solar panels, machine control board, auto car components etc.

Repairs and DIY projects: It's also used for repairing of electronics or electrical devices, or for hobbyists to use for their DIY projects.

How to use Tin Lead Solder Wire Sn63Pb37 63 37:

Manual soldering: we need solder irons or soldering stations to conduct the manual soldering. It's flexible way of manufacturing that allows workers to carry out the soldering work basing on requirements.

Automatic soldering: Ideal for mass production, automatic soldering machines feed and melt the solder wire, ensuring standardized joints.

Precaution for using Tin Lead Solder Wire Sn63Pb37 63 37:

Use in a Well-Ventilated Area: Always solder in a well-ventilated space, such as a fume hood or near an open window, and use exhausting fan. Proper ventilation helps to dissipate harmful fumes and reduce the risk of inhaling lead vapors.

Wear Personal Protective Equipment (PPE): Consider wearing appropriate personal protective equipment, including safety glasses, gloves, and a lab coat or apron, to minimize skin and eye contact with solder and flux.

Avoid Ingestion and Hand-to-Mouth Contact: Never eat, drink, or smoke while working with leaded solder. Wash your hands thoroughly after handling solder and before eating or touching your face.